Chitosan-containing polyether-type polycarboxylate superplasticizer and preparation method thereof

A technology of polyether carboxylic acid and chitosan, applied in the field of concrete admixtures, can solve the problems of low use efficiency of thickeners, poor workability, poor compounding compatibility, etc. Effects of sex and slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

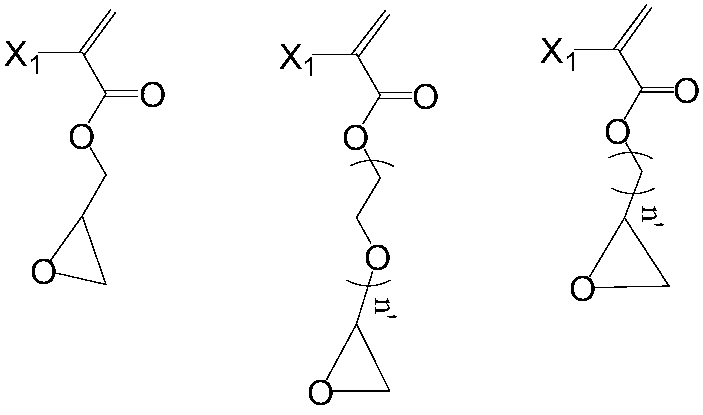

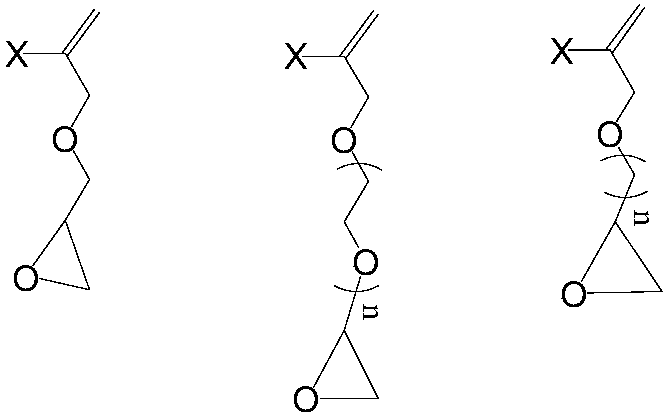

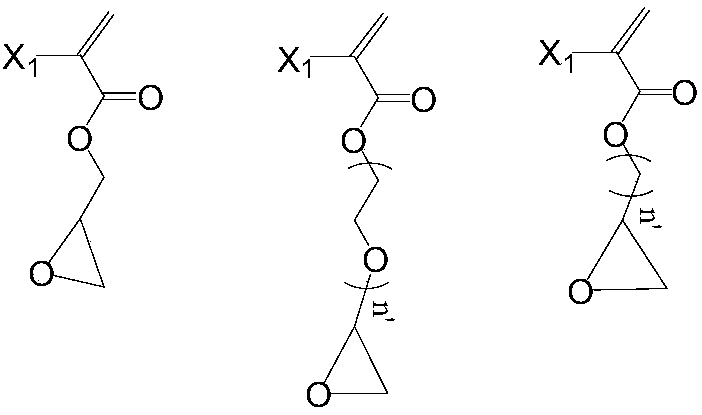

Image

Examples

Embodiment 1

[0052] Example 1: 32 parts of isopentenol polyoxyethylene ether (Mn=2400), 0.6 part of chitosan, 0.6 part of acrylic acid were dissolved in 65 parts of water under stirring, and the reaction system was preheated and controlled after dissolution. The temperature is in the range of 20-60°C, then mix 4.5 parts of acrylic acid, 1.5 parts of maleic anhydride and 0.7 parts of unsaturated carboxylate derivatives containing epoxy groups and drop them into the monomer mixture, while adding 1.9 parts Initiating component solution A (initiating component A, wherein the weight ratio of ammonium persulfate and water is 1:10) and 1.9 parts of initiating component solution B (initiating component solution B consists of thioglycolic acid: ascorbic acid: water The weight ratio is 1.2:1:10), the trigger component solution A and the trigger component solution B were dropped into the mixing system to initiate the reaction. The introduced monomer or initiator is added dropwise within 30-80 minutes...

Embodiment 2

[0053] Example 2: Preheat 50 parts of water to 35°C, then add 16 parts of isopentenol polyoxyethylene ether macromonomer (Mn=2400), 16 parts of allyl polyoxyethylene ether macromonomer under stirring Monomer (Mn=3600), 0.36 parts of water-soluble chitosan and 0.34 parts of unsaturated ether derivatives containing epoxy groups, after the above mixture is dissolved, weigh 7 parts of methacrylic acid and drop into the reaction system, and weigh Get 8 parts of initiating component solution B (the parts by weight of initiating component solution B consist of mercaptopropionic acid: ascorbic acid: water=0.8:1.8:20) and drop into the reaction system; simultaneously 4.8 parts of initiating component solution A (initiating group The composition of the sub-solution A is hydrogen peroxide: potassium persulfate and: water = 1.9:0.9:10) introduced into the polymerization reaction system within 30 minutes, the temperature is controlled not to exceed 65 ° C, the reaction time is not to exceed...

Embodiment 3

[0054] Example 3: 35 parts of methallyl polyoxyethylene ether macromers (Mn=2400), 0.5 parts of epoxy-containing unsaturated carboxylic acid ester derivatives and 8 parts of epoxy-containing unsaturated Saturated ether derivatives, 9 parts of acrylic acid are dissolved in 30 parts of water under stirring, the reaction system is preheated and the temperature is controlled within the range of 0-60°C; then 2.5 parts of the initiator component solution B (initiator component solution The parts by weight of B are composed of thioglycolic acid: ascorbic acid: water=0.44:0.34:8) and 5 parts of initiating component solution A (the parts by weight of initiating component solution A are composed of hydrogen peroxide: water=0.28:1.76) respectively Add dropwise to the polymerization reaction system, and dropwise in 30-60min, continue to react after 20-80min, add 14.5 parts of chitosan solutions (the weight portion of chitosan solution is composed of chitosan: 1 % thioglycolic acid aqueous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com