Preparation method and application of hydrophilic magnetic nanometer material

A magnetic nano-hydrophilic technology, which is applied in the field of preparation of hydrophilic magnetic nano-materials, achieves the effects of good hydrophilicity and magnetic response, high reaction yield, and accelerated stripping process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

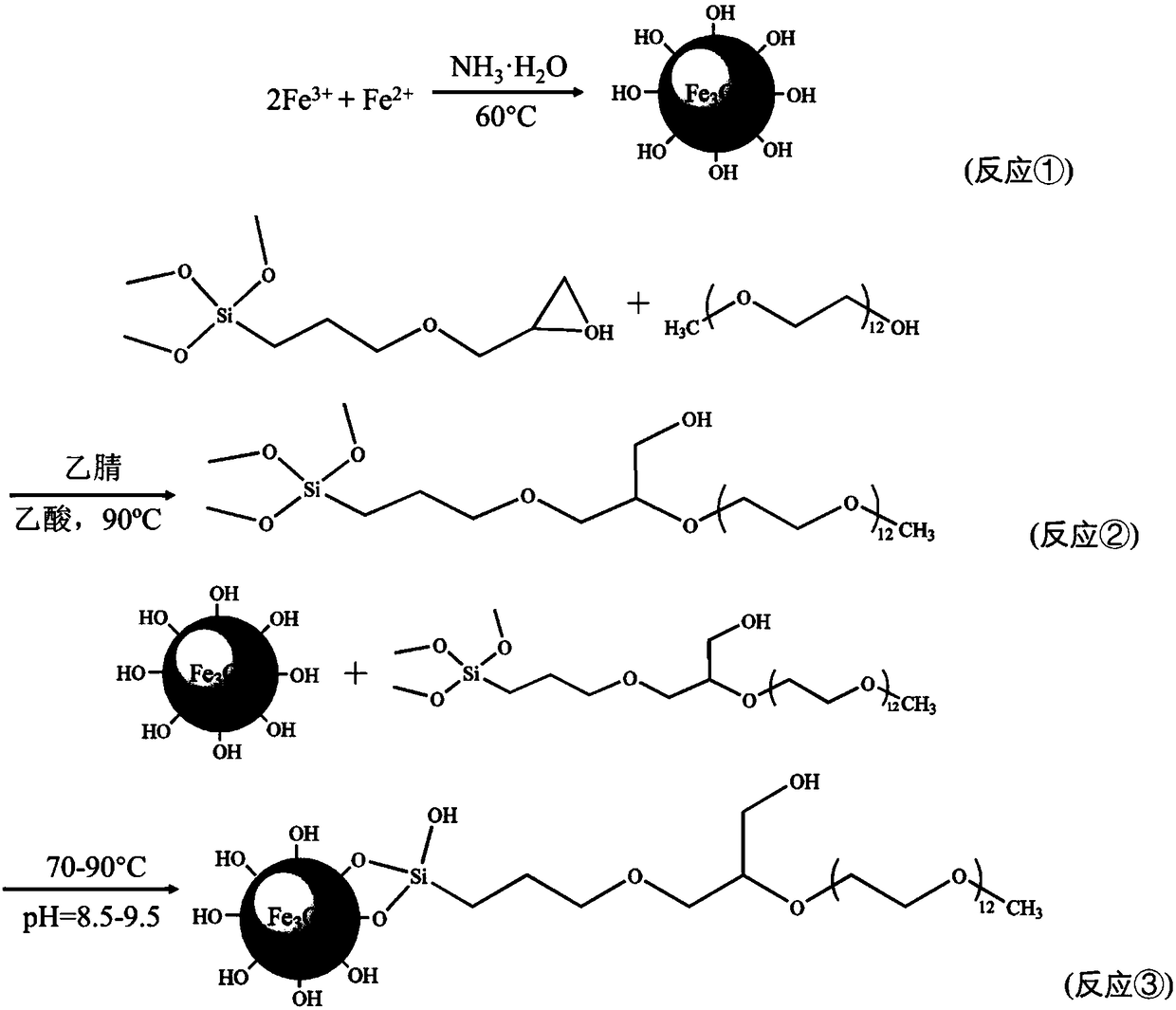

[0053] A kind of synthetic method of PEG modified nano ferric oxide, the steps are as follows:

[0054] ⑴Weigh 0.86g FeCl 2 4H 2 O and 2.34 g FeCl 3 ·6H 2 O was dissolved in 100mL of water, the temperature of the solution was adjusted to 60°C, and 20mL of ammonia water (5%) was slowly added dropwise under stirring at a nitrogen atmosphere of 500r / min, and reacted for 20min to obtain black iron ferric oxide nanoparticles. After the reaction product was separated by a magnet, it was washed twice with ethanol and water to remove excess reactants. The product was dispersed in alkali solution with pH=9.0 and ultrasonically dispersed for 30 minutes.

[0055] (2) Measure 14.00g of PEG600, heat at 90°C for 3h in an inert atmosphere to remove residual moisture, then evenly disperse it in 150mL of acetonitrile solvent, add 0.2mL of acetic acid as a catalyst, add 5.90g of KH560 dropwise, reflux at 90°C, react for 6h, the product Distill at 130 °C for 1 h to remove acetonitrile, aceti...

Embodiment 2

[0058] A kind of synthetic method of PEG modified nano ferric oxide, the steps are as follows:

[0059] ⑴Weigh 0.84g Fe(NH 4 ) 2 (SO 4 ) 2 ·6H 2 O and 0.86g Fe 2 (SO 4 ) 3 Dissolve in 100mL of water, adjust the solution temperature to 80°C, slowly add 15mL of ammonia water (5%) dropwise under a nitrogen atmosphere of 500r / min with stirring, and react for 20min to obtain black ferric oxide nanoparticles. After the reaction product was separated by a magnet, it was washed twice with ethanol and water to remove excess reactants. The product was dispersed in alkali solution with pH=9.0 and ultrasonically dispersed for 20 minutes.

[0060] (2) Take 14.00g of PEG600, heat at 90°C for 3h in an inert atmosphere to remove residual moisture, then evenly disperse it in 150mL of acetonitrile solvent, add 0.15mL of acetic acid as a catalyst, add 5.90g of KH560 dropwise, reflux at 90°C, react for 7h, the product Distill at 130 °C for 1 h to remove acetonitrile, acetic acid and exces...

Embodiment 3

[0063] A kind of synthetic method of PEG modified nano ferric oxide, the steps are as follows:

[0064] ⑴Weigh 0.43g FeCl 2 4H 2 O and 1.17 g FeCl 3 ·6H 2 Dissolve O in 50 mL of water, adjust the temperature of the solution to 60°C, slowly add 10 mL of NaOH (0.10 mol / L) solution dropwise under nitrogen atmosphere with stirring at 350 r / min, and react for 10 min to obtain black iron ferric oxide nanoparticles. After separating the reaction product with a magnet, wash it twice with methanol and water to remove excess reactants. The product is dispersed in alkali solution with pH=9.0 and ultrasonically dispersed for 10 minutes.

[0065] (2) Take 6.00g of PEG400, heat at 90°C for 3h under an inert atmosphere to remove residual moisture, then evenly disperse it in 120mL of acetonitrile solvent, add 0.15mL of acetic acid as a catalyst, add 4.21g of KH560 dropwise, reflux at 90°C, react for 6h, the product Distill at 130 °C for 1 h to remove acetonitrile, acetic acid and excess K...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com