Water gel modified anti-protein pollution ultrafiltration membrane and preparation method thereof

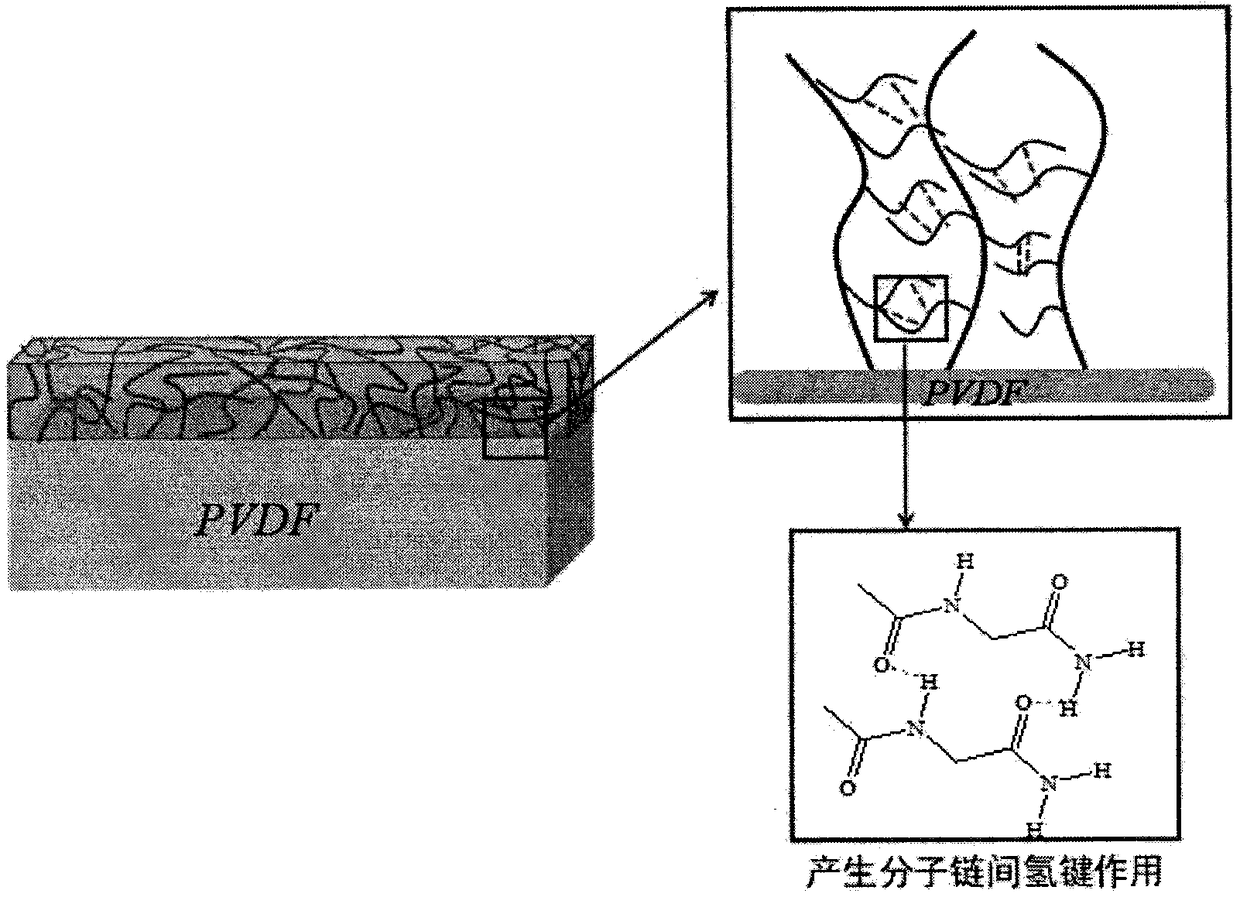

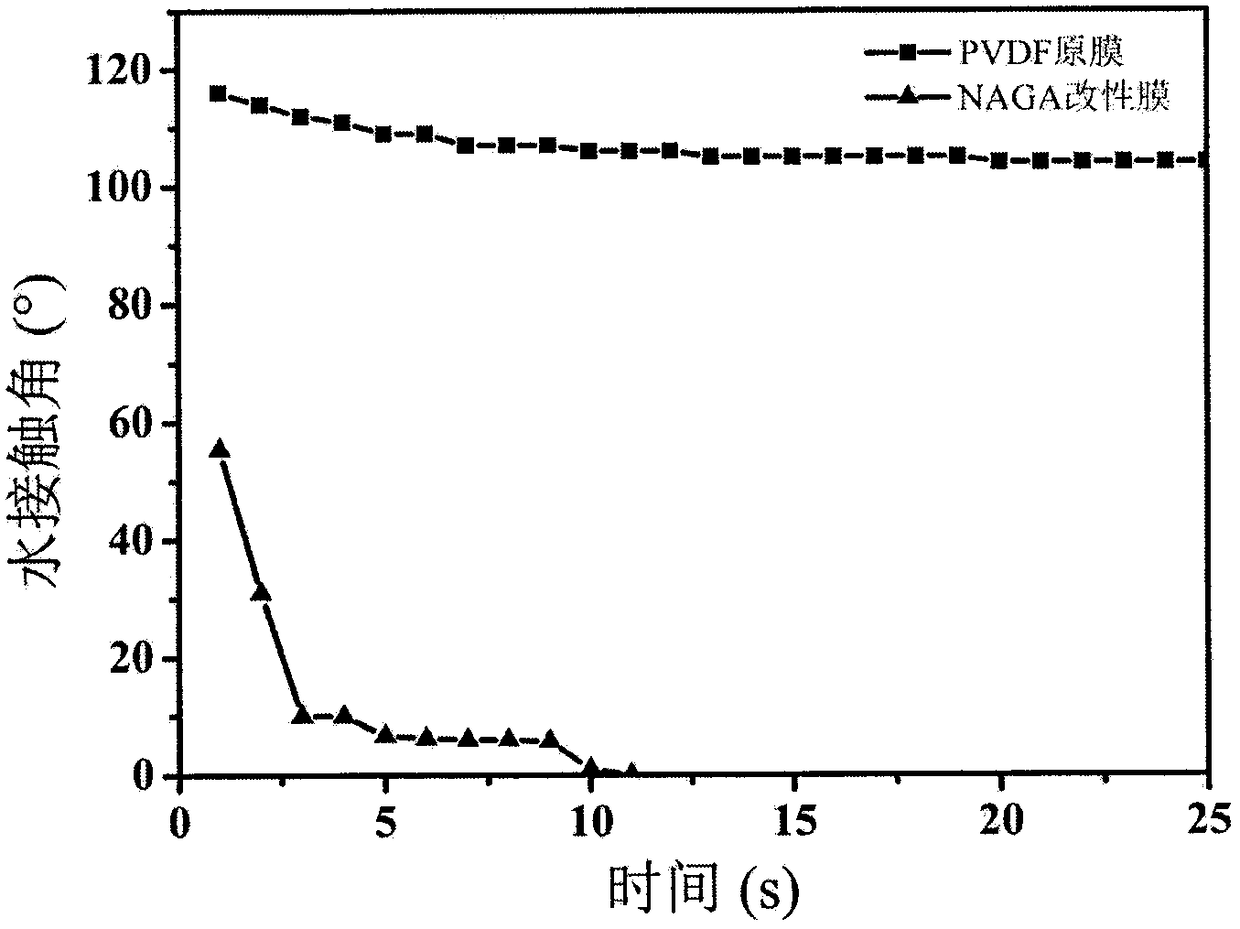

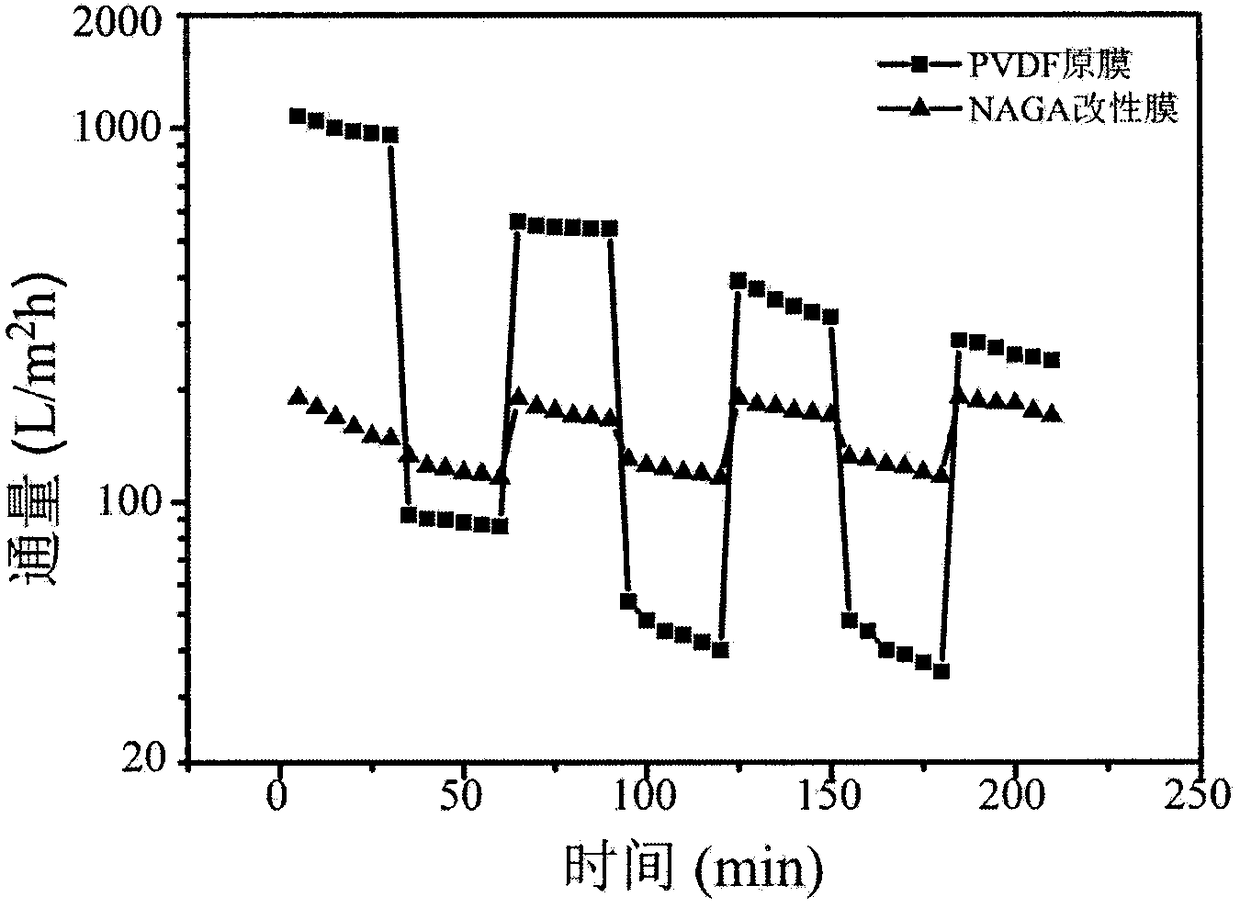

A technology for modifying and membrane surface, which is applied in ultrafiltration, water/sewage treatment, chemical instruments and methods, etc. It can solve the problems of inability to guarantee the stability of the gel layer, affect the resistance to proteins, and complicated operation, and achieve easy cleaning, The effect of good biocompatibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Synthesis of N-acryloyl glycinamide:

[0035] 1) Add glycinamide hydrochloride (6.30g, 0.05706mol), 6mL deionized water, 33.6mL cold potassium carbonate (2mol / L) and 18mL cold ether into a three-necked glass flask (volume 100mL, ice-water mixing bath )middle;

[0036] 2) Add a mixed solution of diethyl ether (24mL) and acryloyl chloride (5.70g) dropwise to the above mixture using a constant pressure separatory funnel, and finish adding dropwise for 1 hour, and continue stirring at room temperature for 4 hours;

[0037] 3) Add 6mol / L HCl dropwise to the above reacted mixture to adjust the pH to 2;

[0038] 4) The above mixture was washed three times with 150 mL of ether, and then the residual ether was removed by rotary evaporation;

[0039] 5) Adjust the pH of the mixture solution to neutral with 2mol / L NaOH, and freeze-dry to obtain the crude product;

[0040] 6) The crude product (N-acryloylglycylamide and potassium chloride, etc.) was washed three times with 1...

Embodiment 2

[0048] (1) Synthesis of N-acryloylglycinamide: same as Example 1.

[0049] (2) Preparation of anti-protein contamination separation membrane:

[0050] 1) The pore size is 0.22μm, the upper surface area is 18cm 2 The PVDF commercial original membrane is cleaned in methanol solution;

[0051] 2) Soak the cleaned PVDF membrane in methanol solution containing benzophenone (0.7mol / L), take it out after 1h and let it dry naturally;

[0052] 3) Weigh 0.4g of N-acryloyl glycinamide, 0.1g of ferrous ammonium sulfate, 11mL of methanol and 39mL of distilled water to make a mixed solution, then transfer it into a quartz tube, pass nitrogen gas for 0.5h, and immerse the dried PVDF membrane in , sealed and preserved;

[0053] 4) Place the sealed quartz tube in an optical density of 6J / cm 2 Irradiate under UV lamp for 35min. The membrane was then removed and washed with methanol and aqueous solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com