Preparation and application method of nano-tin oxide powder co-doped with niobium and indium

A nano-tin oxide and powder technology, applied in tin oxide, oxide conductors, chemical instruments and methods, etc., to achieve good interface bonding, high density, and improved hardness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

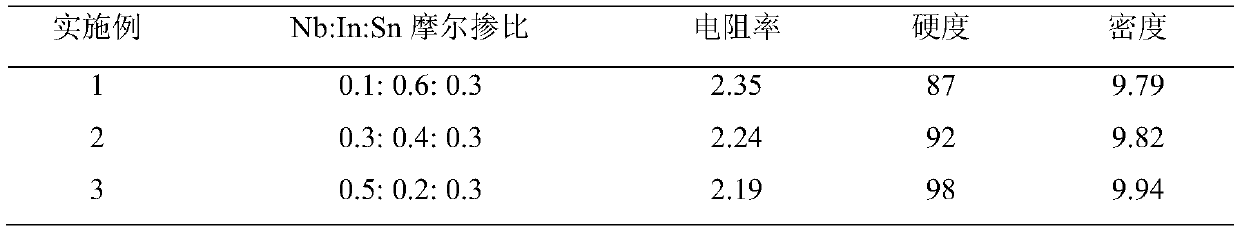

Embodiment 1

[0026] 1.Nb-In co-doped SnO 2 Powder synthesis

[0027] molar ratio (NbCl 5 ):(InCl 3 ):(SnCl 4 ·5H 2 O)=0.1:0.6:0.3 Weigh niobium pentachloride (NbCl 5 ), indium trichloride (InCl 3 ) and tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), put into a beaker and fully dissolve to form a uniform mixed solution, and the NbCl in the mixed solution 5 , InCl 3 and SnCl 4 ·5H 2 The molar percentages of O are 0.1 mol%, 0.6 mol%, and 0.3 mol%, respectively. Then add the complexing agent accounting for 5wt% of the total mass of niobium pentachloride, indium trichloride and tin tetrachloride pentahydrate in the above-mentioned mixed solution, and import in the rotary evaporator and carry out the complexation reaction of metal cation, wherein The complexing agent is citric acid, ethylenediaminetetraacetic acid, oxalic acid. After sufficient complexation, an ammonia solution with a mass concentration of 28 wt.% was added to adjust the pH of the solution, wherein the pH adjustmen...

Embodiment 2

[0032] 1.Nb-In co-doped SnO 2 Powder synthesis

[0033] molar ratio (NbCl5 ):(InCl 3 ):(SnCl 4 ·5H 2 O)=0.3:0.4:0.3 Weigh niobium pentachloride (NbCl 5 ), indium trichloride (InCl 3 ) and tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), put into a beaker and fully dissolve to form a uniform mixed solution, and the NbCl in the mixed solution 5 , InCl 3 and SnCl 4 ·5H 2 The mole percentages of O are 0.3 mol%, 0.4 mol%, and 0.3 mol%, respectively. Then add the complexing agent accounting for 5wt% of the total mass of niobium pentachloride, indium trichloride and tin tetrachloride pentahydrate in the above-mentioned mixed solution, and import in the rotary evaporator and carry out the complexation reaction of metal cation, wherein The complexing agent is citric acid. After sufficient complexation, an ammonia solution with a mass concentration of 28 wt.% is added to adjust the pH of the solution, wherein the pH adjustment range of the solution is pH=7. After that, the ...

Embodiment 3

[0038] 1.Nb-In co-doped SnO 2 Powder synthesis

[0039] molar ratio (NbCl 5 ):(InCl 3 ):(SnCl 4 ·5H 2 O)=0.5:0.2:0.3 Weigh niobium pentachloride (NbCl 5 ), indium trichloride (InCl 3 ) and tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O), put into a beaker and fully dissolve to form a uniform mixed solution, and the NbCl in the mixed solution 5 , InCl 3 and SnCl 4 ·5H 2 The mole percentages of O are 0.5 mol%, 0.2 mol%, and 0.3 mol%, respectively. Then add the complexing agent accounting for 5wt% of the total mass of niobium pentachloride, indium trichloride and tin tetrachloride pentahydrate in the above-mentioned mixed solution, and import in the rotary evaporator and carry out the complexation reaction of metal cation, wherein The complexing agent is ethylenediaminetetraacetic acid. After sufficient complexation, an ammonia solution with a mass concentration of 28 wt.% is added to adjust the pH of the solution, wherein the pH adjustment range of the solution is p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com