Aluminum coated ternary zirconium-doped composite material, composite cathode material, preparation and application thereof in lithium ion batteries

A composite positive electrode material and composite material technology, which is applied in the field of lithium-ion battery positive electrode materials, precursors and their preparation, to achieve the effects of improved stability, excellent performance, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

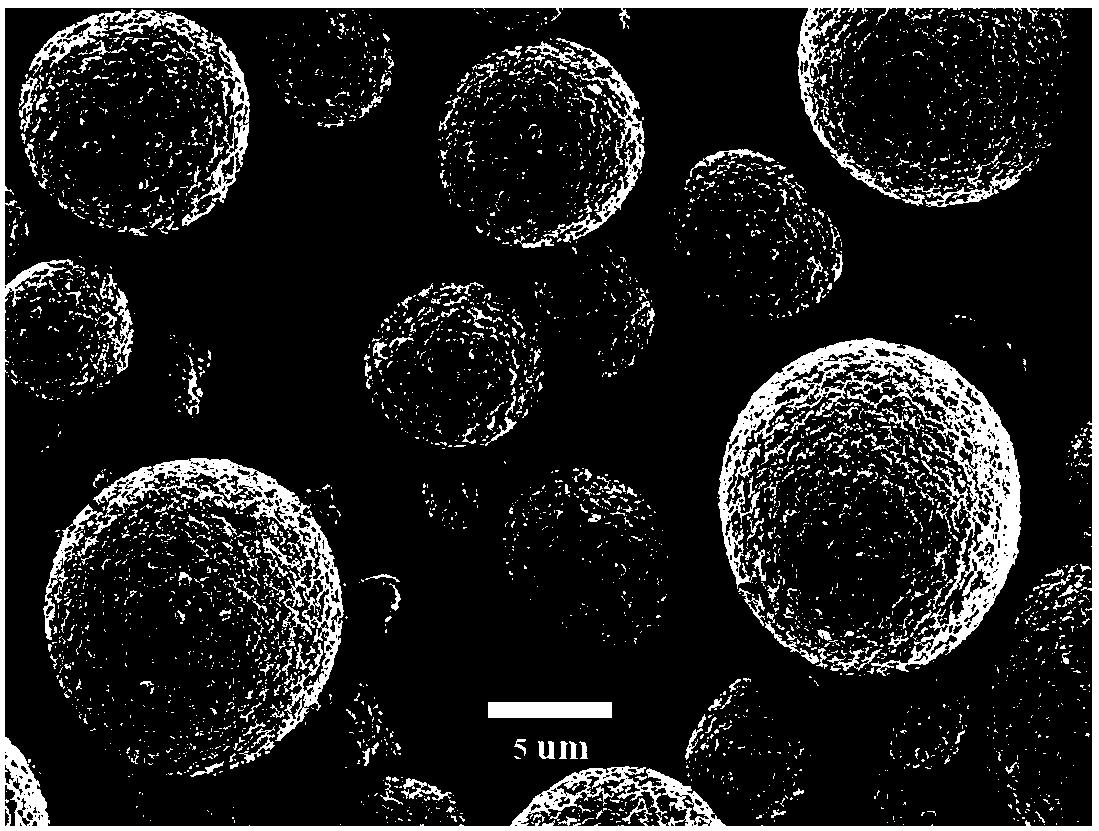

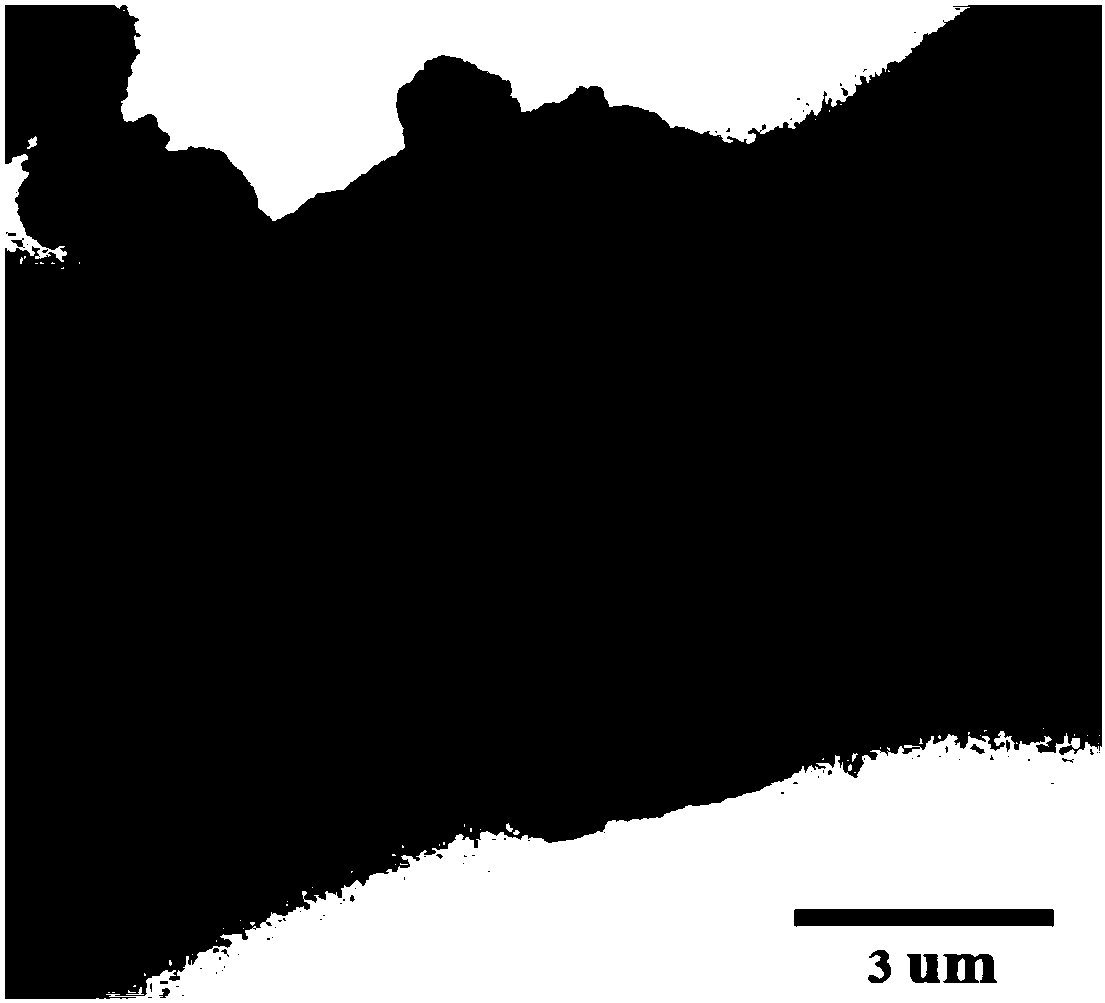

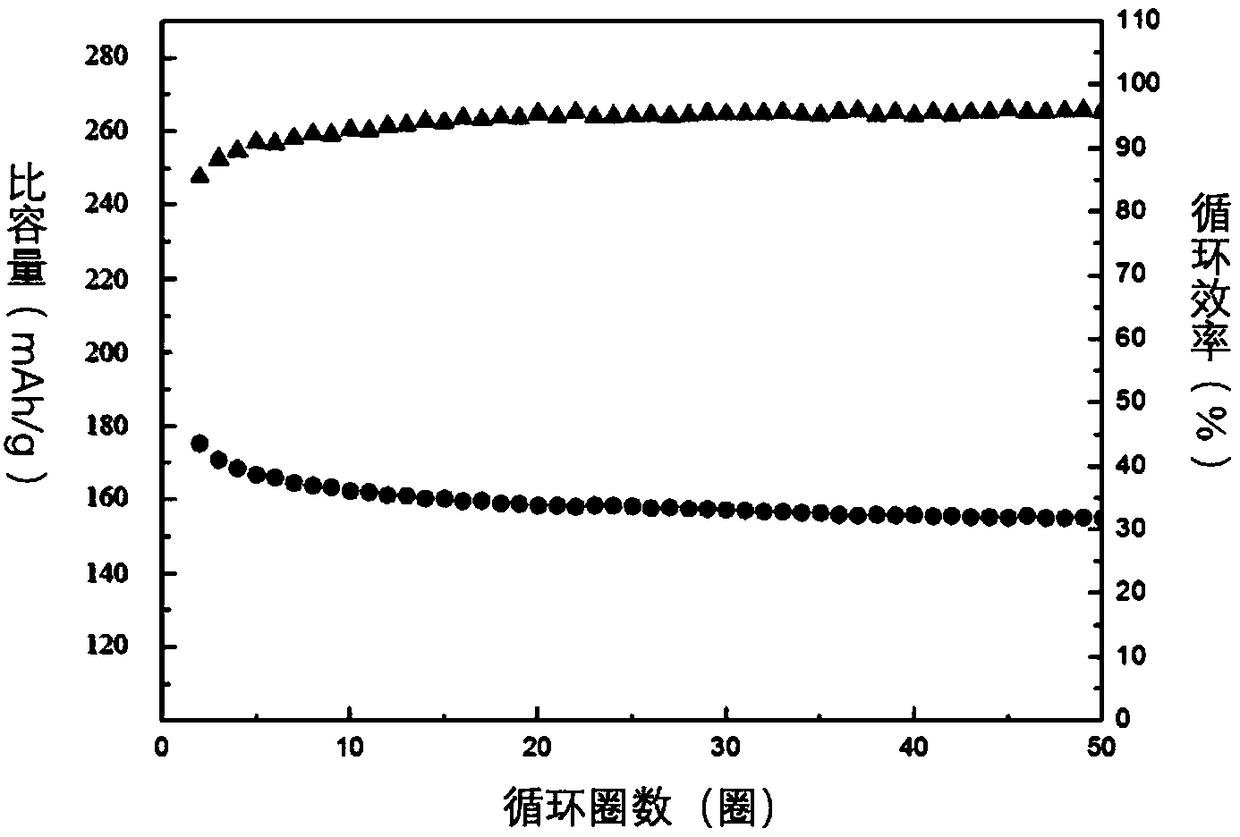

[0086] A metal salt solution with a total metal ion concentration of 1.5 mol / L (Ni, Co, Al, and Zr element ratio of nickel sulfate: cobalt sulfate: aluminum nitrate: zirconium oxychloride = 79: 15: 5:1. Mix the above Add the solution together with ammonia and sodium hydroxide to the reaction kettle containing the bottom liquid (a mixture of ammonia and alkali), adjust the speed of the reaction kettle to 300r / min and the temperature to 55 degrees. Adjust the ammonium concentration of the solution system during the reaction to 8 -9g / L, the pH is 10.5, so that the uniformly mixed nickel, cobalt, aluminum, and zirconium in the solution are co-precipitated according to the stoichiometric ratio. After that, the raw material is stopped and carbon dioxide gas is introduced to adjust the pH=9. Finally, the above precursor The body (aluminum-coated ternary zirconium-doped composite material) is filtered, washed, and dried. The particle diameter D50 of the obtained precursor is 9.5um, the ...

Embodiment 2

[0090] A metal salt solution with a total metal ion concentration of 1.5 mol / L (the element ratio of Ni, Co, Al, and Zr of nickel sulfate: cobalt sulfate: sodium metaaluminate: zirconium chloride = 79.8:15:5:0.2) is prepared. Add the above mixed solution together with ammonia and sodium hydroxide into the reactor containing the sodium hydroxide and ammonia mixture, and adjust the speed of the reactor to 360r / min and the temperature to 50 degrees. Adjust the ammonium concentration of the solution system in the reaction process to 7-8g / L, and the pH to 12, so that the uniformly mixed nickel, cobalt, aluminum, and zirconium in the solution are co-precipitated according to the chemical dose ratio. After that, the feed of raw materials was stopped, and carbon dioxide gas was introduced to adjust the pH=10. Finally, the precursor is filtered, washed, and dried. The particle diameter D50 of the precursor (aluminum-coated ternary zirconium-doped composite material) is 10.3um, the thick...

Embodiment 3

[0094] A metal salt solution with a total metal ion concentration of 1.5 mol / L (Ni, Co, Al, Zr element ratio of nickel sulfate: cobalt sulfate: aluminum sulfate: zirconium sulfate = 77:15:5:3) is prepared. Add the above mixed solution together with ammonia and sodium hydroxide into the reaction kettle containing the bottom liquid (a mixed solution of ammonia and alkali), and adjust the speed of the reaction kettle to 270 r / min and the temperature to 60 degrees. Adjust the ammonium concentration of the solution system in the reaction process to 6.5-7.5g / L, and the pH to 10.3, so that the uniformly mixed nickel, cobalt, aluminum, and zirconium in the solution are co-precipitated according to the chemical dose ratio. After that, the feed of raw materials was stopped, and carbon dioxide gas was introduced to adjust the pH=8.5. Finally, the precursor is filtered, washed, and dried. The particle diameter D50 of the precursor (aluminum-coated ternary zirconium-doped composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com