Activation solution for electroless plating of non-conductive substrate and preparation method thereof

An activation solution and non-conductive technology, which is applied in liquid chemical plating, printed circuit manufacturing, printed circuit, etc., can solve the problems of insufficient adhesion between the chemical plating layer and the substrate, uneven coverage, missing plating, etc., and can be applied to a wide range of plate types performance, good backlight, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

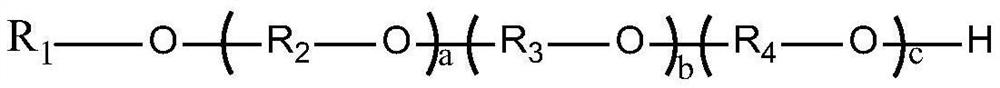

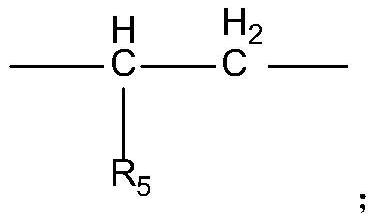

[0059] Referring to the general synthesis method of polymer modifiers, each polymer modifier 1-7 was prepared according to the ingredients listed in Table 1, the structure of each monomer and the number of repeating units.

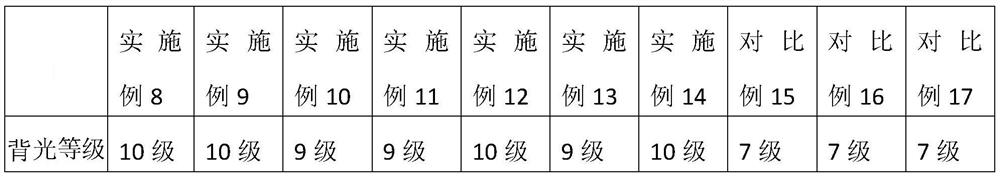

[0060] Table 1

[0061]

[0062]

[0063] Wherein, the preparation method of polymer regulator in embodiment 1 comprises the steps:

[0064] Add 1 part of isobutanol into the stainless steel reaction kettle, and pass in nitrogen gas. After the oxygen content in the kettle is less than 100ppm, add an appropriate amount of potassium hydroxide in a closed manner, raise the temperature to 80°C, continue to pass in nitrogen to pressurize, and raise the temperature to 110°C, and the pressure is 0.3 MPa, continuously add 10 parts of propylene oxide, react for 12 hours, lower the temperature, dehydrate, and the obtained intermediate product is directly used for the subsequent reaction.

[0065] Add an appropriate amount of potassium hydroxide to the reactio...

Embodiment 8

[0069] Preparation of activation solution: 150mg of palladium chloride (calculated as palladium ion concentration) and 250mg of acetylacetone were dissolved in 1L of deionized water, then 75mg of the polymer regulator prepared in Example 1 was added and fully stirred to dissolve, and finally 8.4g / L of aqueous sodium bicarbonate solution to adjust the pH to 7.5.

[0070] Electroless copper plating: The glass fiber through-hole plate with a thickness of 2.5mm and an aperture ratio of 10:1 is firstly subjected to expansion, degumming, neutralization, degreasing, micro-etching, and pre-dipping operations in sequence according to the conventional copper deposition process, and then At room temperature, immerse in the palladium activation solution obtained above for 60 seconds, and finally treat it with 0.1% sodium borohydride aqueous solution for 40 seconds for reduction. EDTA disodium salt, 15mg / L formaldehyde and 13g / L sodium hydroxide in the electroless copper plating solution,...

Embodiment 9

[0072] Preparation of activation solution: 300mg of palladium chloride (calculated as palladium ion concentration) and 450mg of acetylsalicylic acid were dissolved in 1L of deionized water, then 100mg of the polymer regulator prepared in Example 2 was added and fully stirred to dissolve, and finally 3.6 g / L aqueous potassium hydroxide solution to adjust the pH to 12, and place the solution in a water bath at 45°C for later use.

[0073] Electroless copper plating: The resin through-hole plate with a thickness of 2.5mm and an aperture ratio of 10:1 is firstly subjected to expansion, degumming, neutralization, degreasing, microetching, and pre-dipping operations in sequence according to the conventional copper plating process, and then immersed in In the above-mentioned palladium activation solution for 15 seconds, then through the same reduction and electroless copper plating process as in Example 8, copper plating is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com