Biodegradable iron-zinc alloy and preparation method thereof

An iron-zinc and biological technology, applied in the field of biodegradable iron-zinc alloy and its preparation, can solve the problems of hindering the corrosion process of the iron-zinc alloy substrate, slow electrodeposition speed, and large difference in melting point, etc. Degradability and mechanical properties, fast cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Use 50μm iron powder and 50μm zinc powder as raw materials, weigh 0.9g iron powder and 0.1g zinc powder according to the mass ratio of 90:10, and ball mill under the protection of 99.999% high-purity argon gas. 10:1, ball milling time 40h, iron-zinc supersaturated solid solution alloy powder is obtained after ball milling.

[0048] The obtained iron-zinc supersaturated solid solution alloy powder is placed in the molding chamber of the optical fiber sintering system, and the sintering temperature is controlled under the technological conditions of 99.999% high-purity argon gas protection, a spot diameter of 100 μm, a laser power of 180W, and a scanning speed of 10mm / s The temperature is 1300 ℃, and the biodegradable iron-zinc alloy is prepared by selective laser melting process.

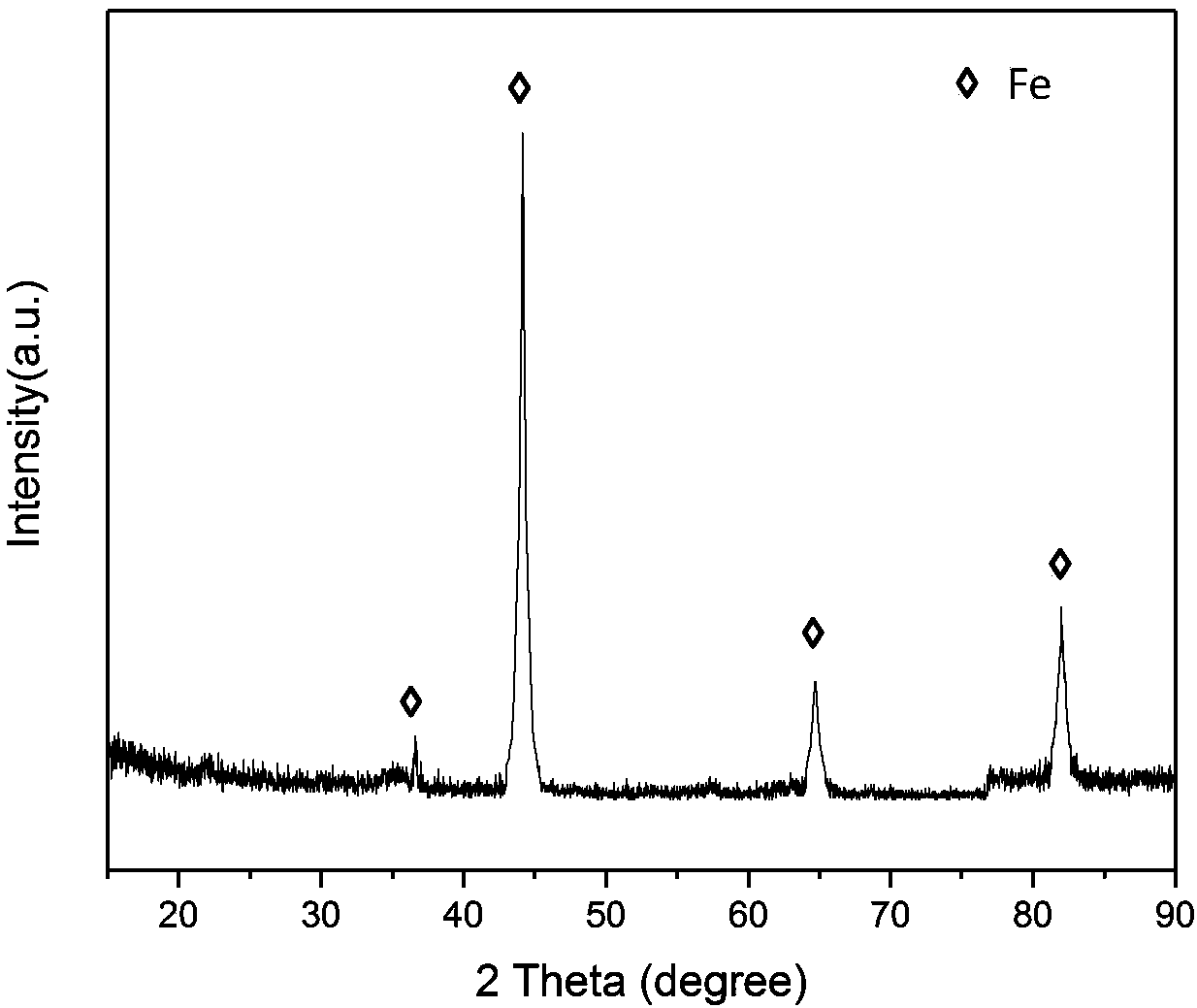

[0049] Phase detection found ( figure 1 ), the prepared iron-zinc alloy only has iron diffraction peaks, indicating that zinc is completely dissolved in the iron matrix to form a supersaturate...

Embodiment 2

[0053] Use 50μm iron powder and 50μm zinc powder as raw materials, weigh 0.9g iron powder and 0.1g zinc powder according to the mass ratio of 90:10, and ball mill under the protection of 99.999% high-purity argon gas. 10:1, ball milling time 40h, iron-zinc supersaturated solid solution alloy powder is obtained after ball milling.

[0054] Under the technological conditions of 99.999% high-purity argon protection, spot diameter of 100 μm, laser power of 100 W, and scanning speed of 25 mm / s, the sintering temperature was controlled at 1000 ° C, and the iron-zinc alloy was prepared by selective laser melting process.

[0055] Phase detection found that the prepared iron-zinc alloy only had iron diffraction peaks, indicating that zinc was completely dissolved in the iron matrix to form a supersaturated solid solution; the grain size was 5-12 μm; electrochemical analysis found that the iron-zinc alloy was Corrosion potential in -0.64V, corrosion current density 6.92μA / cm 2 , the c...

Embodiment 3

[0057] Use 50μm iron powder and 50μm zinc powder as raw materials, weigh 0.9g iron powder and 0.1g zinc powder according to the mass ratio of 90:10, and ball mill under the protection of 99.999% high-purity argon gas. 10:1, ball milling time 40h, iron-zinc supersaturated solid solution alloy powder is obtained after ball milling.

[0058] Under the technological conditions of 99.999% high-purity argon protection, spot diameter of 100 μm, laser power of 80 W, and scanning speed of 30 mm / s, the sintering temperature was controlled at 800 ° C, and the iron-zinc alloy was prepared by selective laser melting process.

[0059] Phase detection found that the prepared iron-zinc alloy only had iron diffraction peaks, indicating that zinc was completely dissolved in the iron matrix to form a supersaturated solid solution; the grain size was 5-10 μm; electrochemical analysis found that the iron-zinc alloy was Corrosion potential in -0.65V, corrosion current density 5.61μA / cm 2 , the cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com