Transitional metal phosphide-carbon composite material as well as preparation method and application thereof

A technology of carbon composite materials and transition metals, applied in nanotechnology, electrochemical generators, electrical components, etc. for materials and surface science, can solve problems affecting battery cycle performance, powdering of electrode materials, volume expansion, etc. Achieve the effect of improving the kinetic process of the electrode reaction, good rate performance, and avoiding particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of transition metal phosphide-carbon composite material, comprises the following steps:

[0031] (1) adding the transition metal ion salt solution dropwise to the carbon precursor suspension to carry out a complexation reaction to obtain a complexation solution, the carbon precursor being egg shells, shrimp shells or chitosan;

[0032] (2) mixing the complex solution, potassium hydroxide and phosphorus source obtained in the step (1) and evaporating to dryness to obtain a transition metal phosphide-carbon composite material precursor;

[0033] (3) in an inert atmosphere, the transition metal phosphide-carbon composite material precursor obtained in the step (2) is roasted to obtain a roasted product;

[0034] (4) soaking the calcined product obtained in the step (3) in mineral acid to obtain a transition metal phosphide-carbon composite material.

[0035] In the invention, the transition metal ion salt solution is add...

Embodiment 1

[0065] (1) Add 1.2g of egg shells into 100ml of deionized water, and stir for 2 hours by magnetic force.

[0066] (2) Dissolve 1 mmol of nickel acetate in a small amount of deionized water, add dropwise to the above liquid under constant stirring, and stir magnetically for 3 hours.

[0067] (3) Add 1.2g of potassium hydroxide solution and keep stirring, then add 1.2g of red phosphorus and stir for 1 hour, evaporate to dryness at 80°C, and dry in a 70°C drying oven.

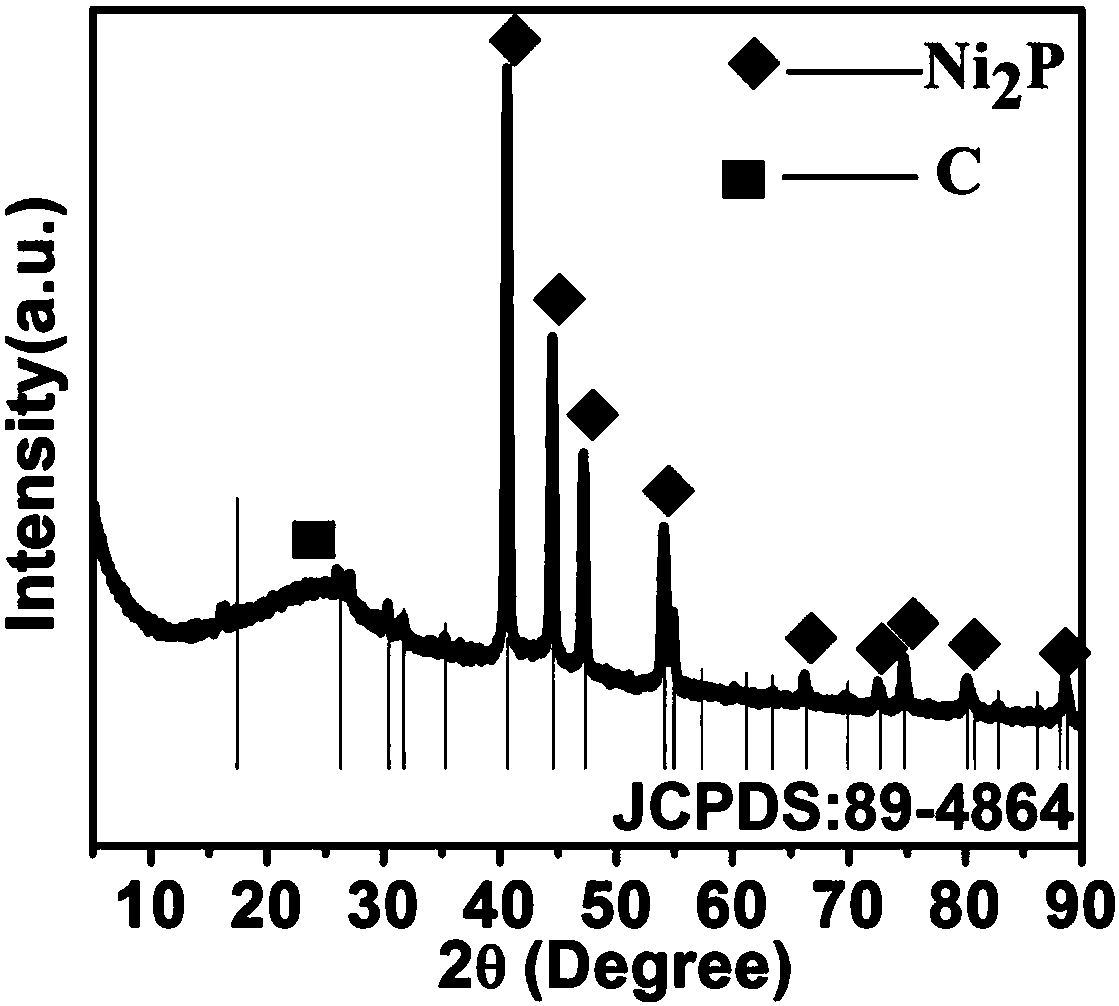

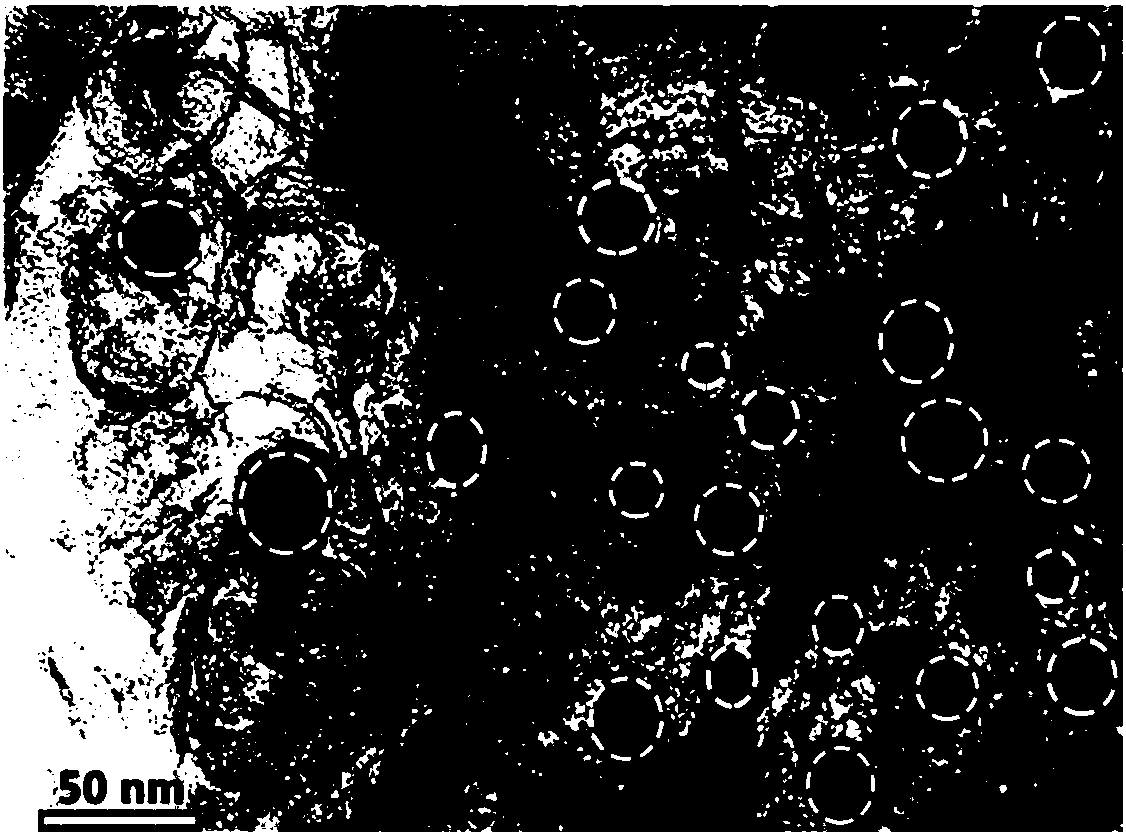

[0068] (4) Keep the temperature at 700°C for 2 hours in an inert gas atmosphere, and the heating rate is 2°C / min. After naturally cooling to room temperature, the obtained product was washed with 1M HNO 3 After immersing in ultrasound for 20 min, wash with deionized water and ethanol three times, and dry in a 70°C drying oven to obtain a transition metal phosphide-carbon composite (Ni 2 P@NPC).

Embodiment 2

[0070] (1) Add 1.2g of chitosan into 100ml of deionized water, and stir for 4 hours by magnetic force.

[0071] (2) Dissolve 2 mmol of nickel acetate in a small amount of deionized water, add dropwise to the above liquid under constant stirring, and stir magnetically for 2 hours.

[0072] (3) Add 2.4g of potassium hydroxide solution and keep stirring, then add 2.4g of red phosphorus and stir for 1 hour, evaporate to dryness at 80°C, and dry in a 70°C drying oven.

[0073] (4) Keep warm at 700°C for 2h in an inert gas atmosphere. After naturally cooling to room temperature, the obtained product was treated with 2MHNO 3 After immersing in ultrasound for 20 min, wash with deionized water and ethanol three times, and dry in a 70°C drying oven to obtain a transition metal phosphide-carbon composite (Ni 2 P@NPC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com