Compound preservative containing capryloyl hydroxamic acid and preparation method thereof

A technology of caprylyl hydroxamic acid and compound preservatives, which is applied in the field of cosmetics, can solve the problems that it is difficult to achieve a balanced antibacterial state of the system, difficult to achieve antibacterial effect, difficult to dissolve and disperse, and achieve stable antibacterial effect and antibacterial effect. Wide range of bacteria, the effect of inhibiting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

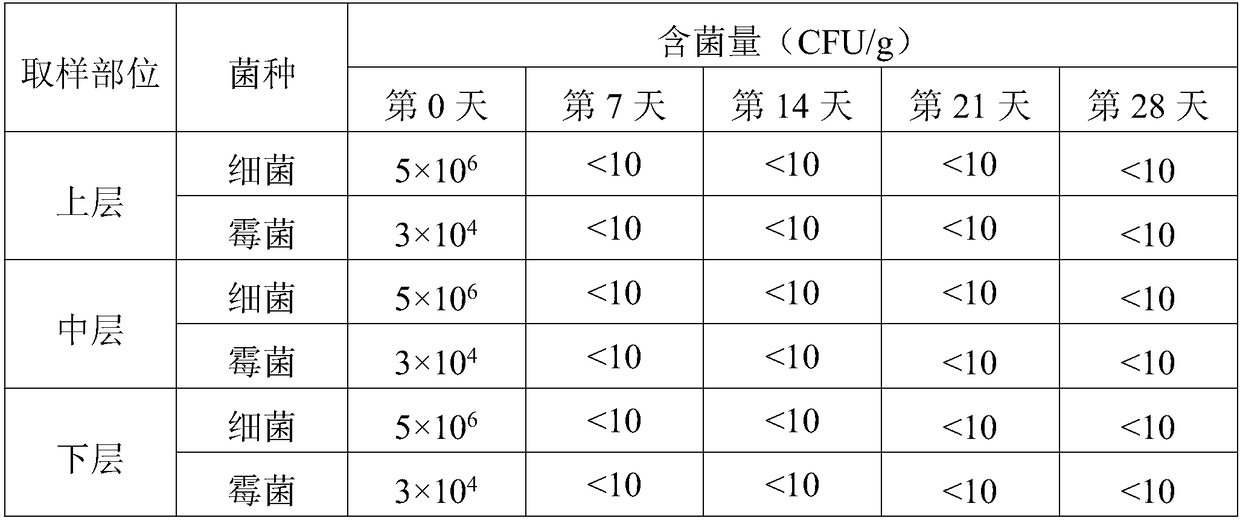

[0023] Embodiment 1 A kind of facial mask liquid containing compound preservative

[0024] It is made from the following raw materials and their mass percentages: 2% water-soluble chitosan, 1% loofah water, 8% glycerin, 0.6% compound preservative and the balance sterile water.

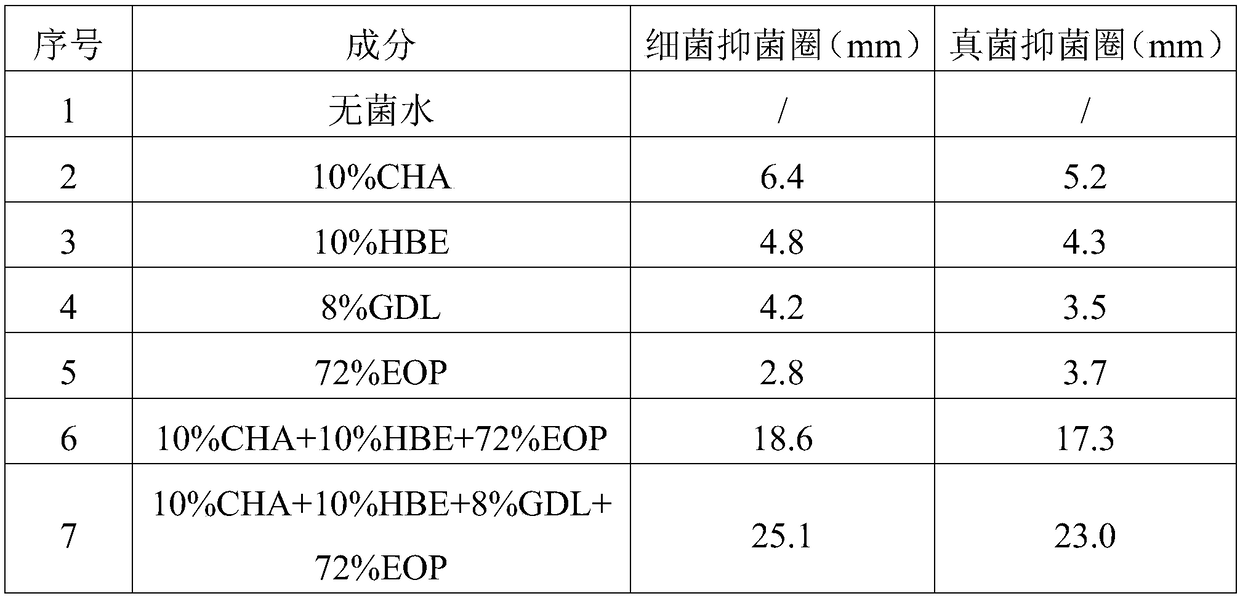

[0025] Wherein, the compound preservative is made of the following raw materials and their mass percentages: caprylyl hydroxamic acid 10%, p-hydroxyacetophenone 10%, glucono-δ-lactone 8% and ethylhexylglycerin 72% .

[0026] Preparation:

[0027] S1. Preparation of compound preservatives: Take the corresponding amount of ethylhexylglycerin and glucono-δ-lactone in the reaction kettle, stir and heat to 45°C, add the corresponding amount of caprylyl hydroxamic acid and p-hydroxyphenylethyl ether Ketone, continue to stir until uniform, cool to room temperature, fill, and obtain;

[0028] S2, preparation of facial mask liquid: get corresponding amount of sterile water, add corresponding amount of glyce...

Embodiment 2

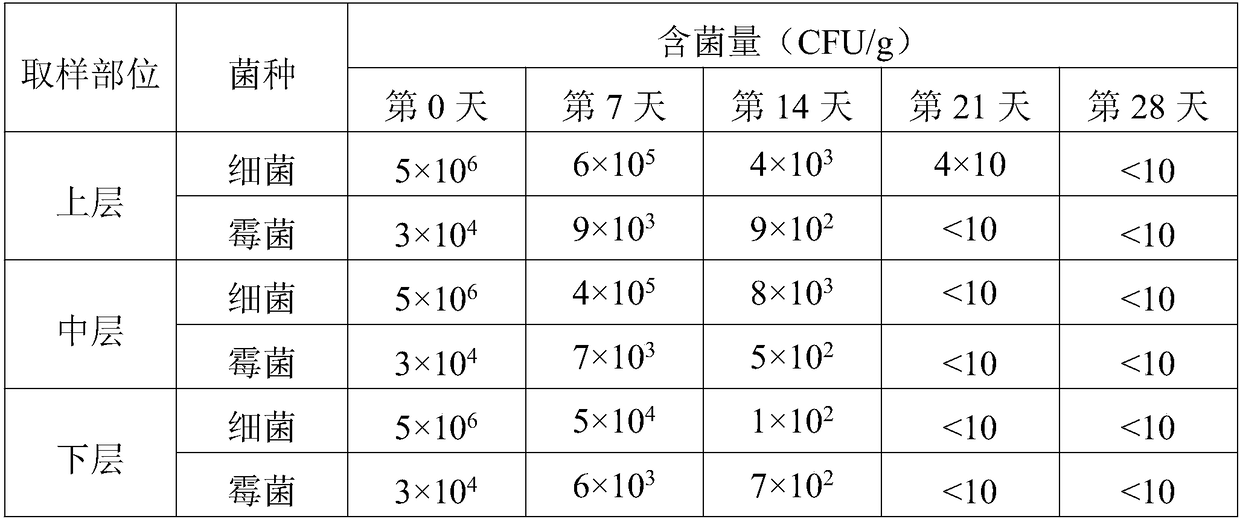

[0029] Embodiment 2 A kind of skin lotion containing compound antiseptic

[0030] It is made of the following raw materials and their mass percentages: 10% of plant extracts, 15% of glycerin, 8% of glycerol monostearate, 15% of wheat germ oil, 1% of compound preservatives and the balance of sterile water.

[0031] Wherein, the compound preservative is made of the following raw materials and their mass percentages: caprylyl hydroxamic acid 12%, p-hydroxyacetophenone 8%, glucono-δ-lactone 8% and ethylhexylglycerin 72% .

[0032] Preparation:

[0033] S1, preparation of compound antiseptic: reference example 1;

[0034] S2. Preparation of body lotion: Take the corresponding amount of glycerin monostearate and wheat germ oil and heat to 80°C, stir until completely dissolved to obtain mixture A; heat the corresponding amount of glycerin and sterile water to 90°C, and stir until Completely dissolve to obtain mixture B; mix mixture A and mixture B evenly, stir and emulsify, adju...

Embodiment 3

[0035] Embodiment 3 A kind of hand sanitizer containing compound antiseptic

[0036] Made from the following raw materials and their mass percentages: oil 6%, alkali 3%, absolute ethanol 5.5%, essence 0.2%, pigment 0.2%, fatty acid polyoxyethylene ether sodium sulfate 5%, lauryl dimethyl beet Alkali 3%, compound preservative 0.5% and the balance sterile water.

[0037] Wherein, the compound preservative is made of the following raw materials and their mass percentages: caprylyl hydroxamic acid 10%, p-hydroxyacetophenone 8%, glucono-δ-lactone 6% and ethylhexylglycerin 76% .

[0038] Preparation:

[0039] S1, preparation of compound antiseptic: reference example 1;

[0040] S2. Preparation of hand sanitizer: Take the corresponding amount of oil, alkali, absolute ethanol, essence, pigment, fatty acid polyoxyethylene ether sodium sulfate, lauryl dimethyl betaine, compound preservative and sterile water to mix, Stir and heat to 70-80°C, mix evenly, cool down, and fill and pack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com