Double-layer structure flexible piezoelectric film with high output, preparation and application method thereof

A double-layer structure, flexible piezoelectric technology, applied to piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric devices or electrostrictive devices, circuits, etc., can solve the problem of decreased flexibility, The problems of high modulus of inorganic nanofillers and increased modulus of composite materials can achieve the effect of maintaining flexibility, increasing dielectric constant, and enhancing piezoelectric output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

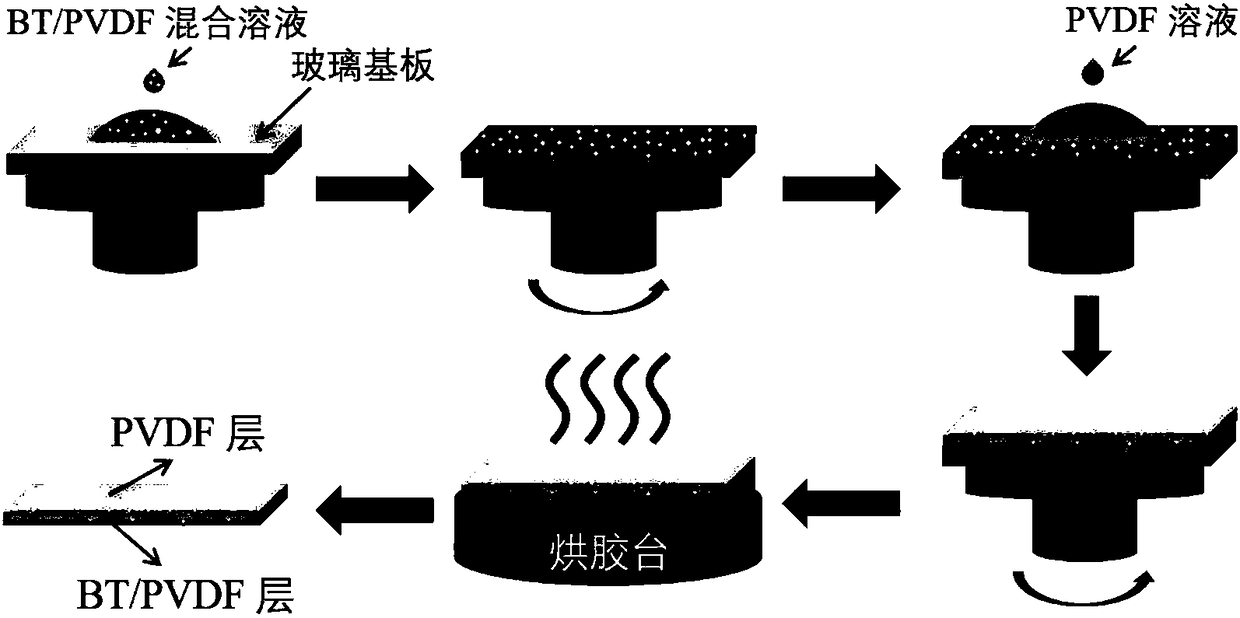

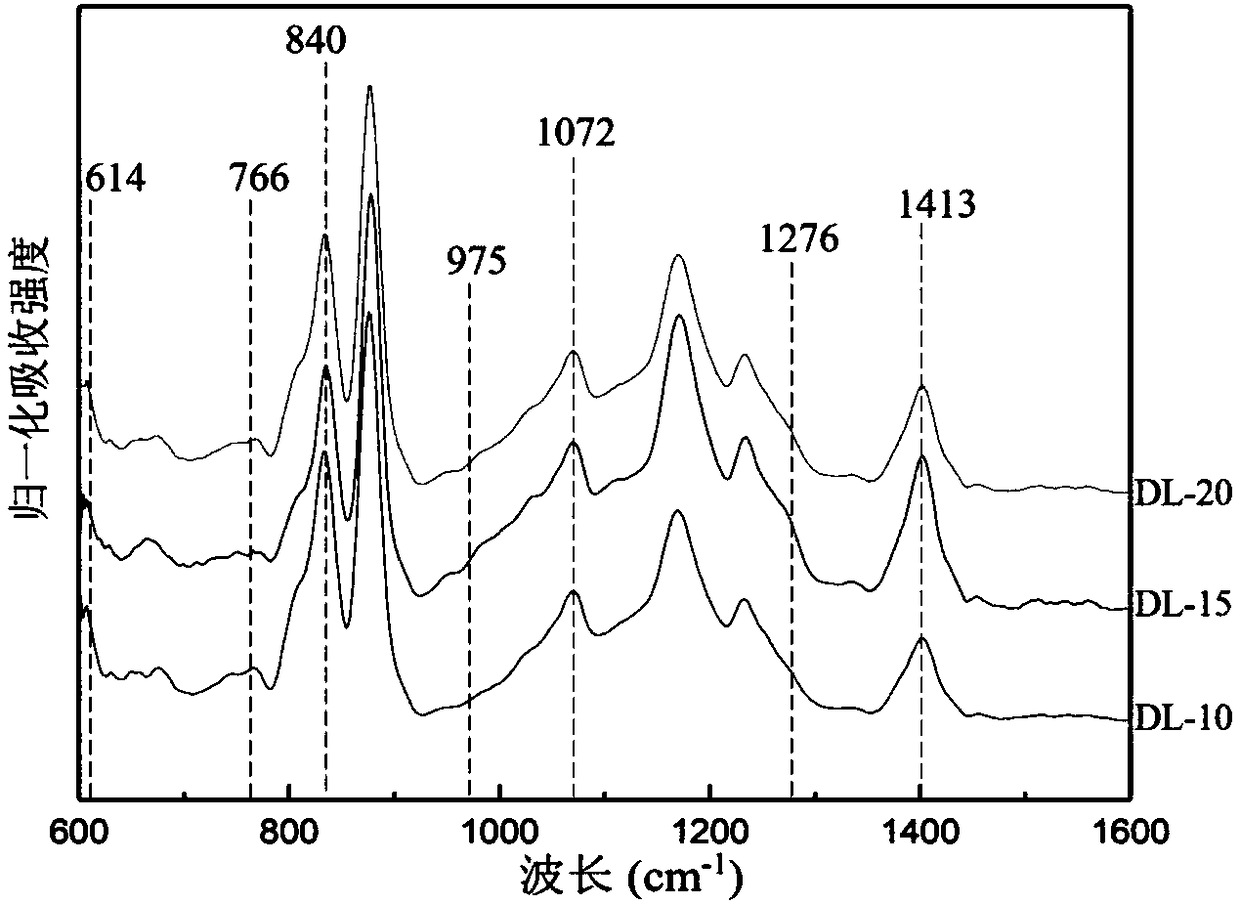

Embodiment 1

[0029] Weigh 0.5618g of surface-modified BT nanoparticles in a beaker, add 7.5mL of nitrogen-nitrogen dimethylformamide (DMF), ultrasonically disperse for 2h to form a uniform suspension, then add 1.5g of PVDF powder thereto, Stir magnetically at 30°C for 12 hours to dissolve completely. Spin coating - heat treatment process as attached figure 1 Shown: Put the mixed solution in a vacuum drying oven to pump air bubbles, turn on the homogenizer, put on the cleaned and ultrasonically treated glass slide in ethanol, then use a straw to absorb 2mL of the mixed solution, drop it on the glass slide, and perform a single Layer thin film spin coating. Spin coating at 500rpm for 10s, and then at 1000rpm for 15s. The slow speed is for the solution to be spread evenly on the glass sheet, and the fast speed is for ensuring uniform film thickness. Put the single-layer film on the rubber drying table, bake at 150°C for 2 hours (to ensure that the solvent is dried), and cool down to 40°C (t...

Embodiment 2

[0031] Weigh 0.8923g of surface-modified BT nanoparticles into a beaker, add 7.5mL of DMF, ultrasonically disperse for 2h to form a uniform suspension, then add 1.5g of PVDF powder to it, and stir magnetically at 30°C for 12h to make it completely dissolve. Put the mixed solution in a vacuum drying oven to pump air bubbles, turn on the homogenizer, put the cleaned and ultrasonically treated glass slide in ethanol, then use a straw to absorb 2mL of the mixed solution, drop it on the glass slide, and spin the single-layer film. painted. Spin coating at 600rpm for 10s, then spin coating at 1200rpm for 10s, place the single-layer film on the rubber drying table, bake at 160°C for 2h, cool down to 40°C, and apply the second layer of the single-layer film on the glass sheet Pure PVDF is spin-coated under the same spin-coating conditions, and the solvent is completely dried at 70°C for 10 hours. The double-layer film is removed from the glass substrate to obtain the BT / PVDF-PVDF do...

Embodiment 3

[0033] Weigh 1.2640g of surface-modified BT nanoparticles in a beaker, add 7.5mL of nitrogen nitrogen dimethylformamide (DMF), ultrasonically disperse for 2h to form a uniform suspension, then add 1.5g of PVDF powder thereto, Stir magnetically at 30°C for 12 hours to dissolve completely. Put the mixed solution in a vacuum drying oven to pump air bubbles, turn on the homogenizer, put the cleaned and ultrasonically treated glass slide in ethanol, then use a straw to absorb 2mL of the mixed solution, drop it on the glass slide, and spin the single-layer film. painted. Spin-coat at 600rpm for 10s, then spin-coat at 1500rpm for 10s, place the single-layer film on the rubber drying table, bake at 150°C for 2 hours, cool down to 40°C, and apply the second layer of the single-layer film on the glass sheet Pure PVDF is spin-coated under the same spin-coating conditions, and the solvent is completely dried at 70°C for 10 hours. The double-layer film is taken off from the glass substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com