Preparation method of N-doped carbon/manganese dioxide composite electrode materials of porous communication network

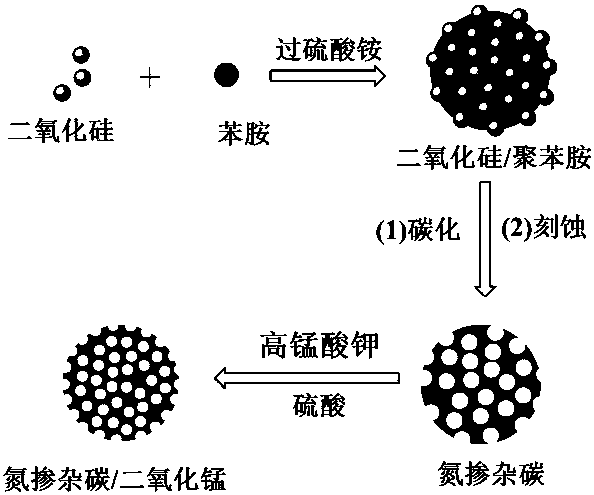

A technology of nitrogen-doped carbon and manganese dioxide, which is used in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, can solve the problems of low conductivity and poor electrochemical performance of manganese dioxide, and achieve excellent performance and improved performance. Hydrophilic and conductive, dispersing effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Disperse 5.7 g of ammonium persulfate in 50 mL of aqueous hydrochloric acid solution with a concentration of 1 mol / L to prepare an oxidant mixture, and refrigerate at 0°C for 0.5 h until use;

[0035] (2) Disperse 4.6g of silica sol (with a particle size of 20nm) in 50 mL of aqueous hydrochloric acid solution with a concentration of 1 mol / L, ultrasonically disperse for 0.5 h, and the ultrasonic frequency is 40 kHz;

[0036] (3) Add 2 mL of aniline to the silicon dioxide hydrochloric acid mixture in step (2), and disperse for 0.5 h with mechanical stirring at a stirring speed of 300 rpm and ultrasonic frequency at 40 kHz, and keep the temperature of the mixed liquid at 0°C.

[0037] (4) To the silica / aniline mixed solution in step (3), add dropwise the oxidant mixed solution in step (1) refrigerated for use; after the oxidant mixed solution has been added dropwise, mechanically Stirring and ultrasonic frequency of 40 kHz were used to disperse for 2 h, and the temper...

Embodiment 2

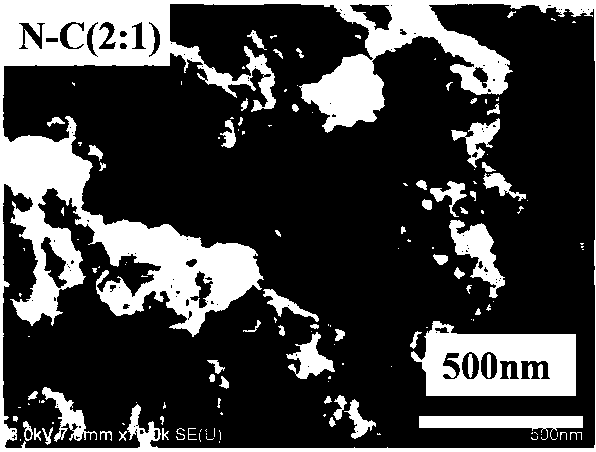

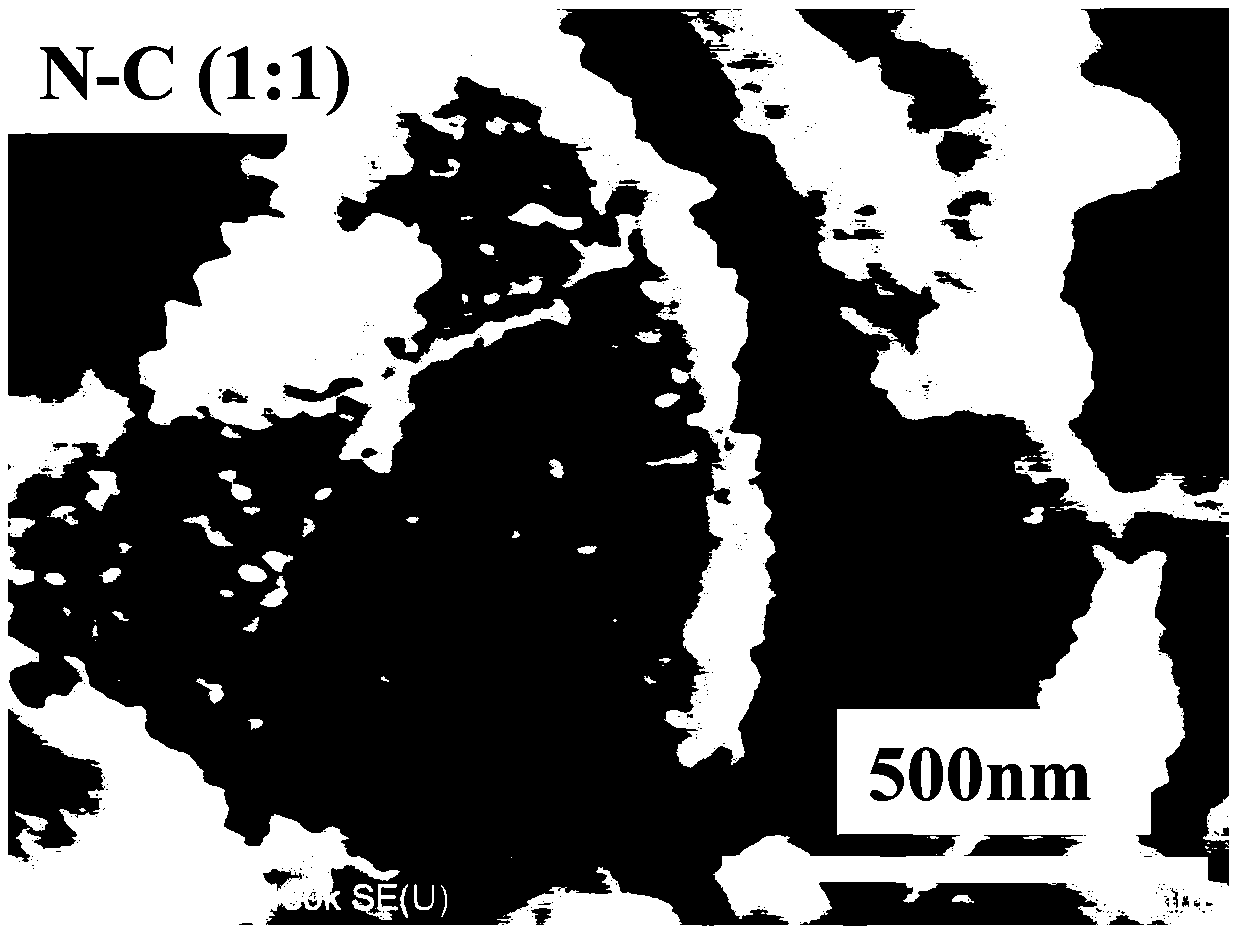

[0043] On the basis of the preparation in Example 1, the amount of silica sol was adjusted to: 2.3g;

[0044] The nitrogen-doped carbon material of the porous interconnection network prepared in this embodiment is marked as N-C (1:1), and its scanning electron microscope picture is shown in image 3 .

[0045] After high temperature carbonization and alkali etching, from image 3 The obtained nitrogen-doped carbon material is fiber-type, and many protrusions are formed on the surface of the fiber.

Embodiment 3

[0047] On the basis of the preparation of Example 1, the amount of silica sol was adjusted to: 6.9g;

[0048] The nitrogen-doped carbon material of the porous interconnection network prepared in this embodiment is marked as N-C (3:1), and its scanning electron microscope picture is shown in Figure 4 , the obtained nitrogen-doped carbon material is an irregular spherical shape, and the surface of the spherical shape contains holes of different sizes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap