Chip epitaxial structure of low-resistance LED and preparation method thereof

An epitaxial structure and chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problem of reducing the contact resistance of P-type semiconductor materials/P-type electrodes, increasing hole injection efficiency, and poor hole injection efficiency and other issues, to achieve the effect of improving photoelectric conversion efficiency, improving I-V characteristics, and alleviating the effect of current crowding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

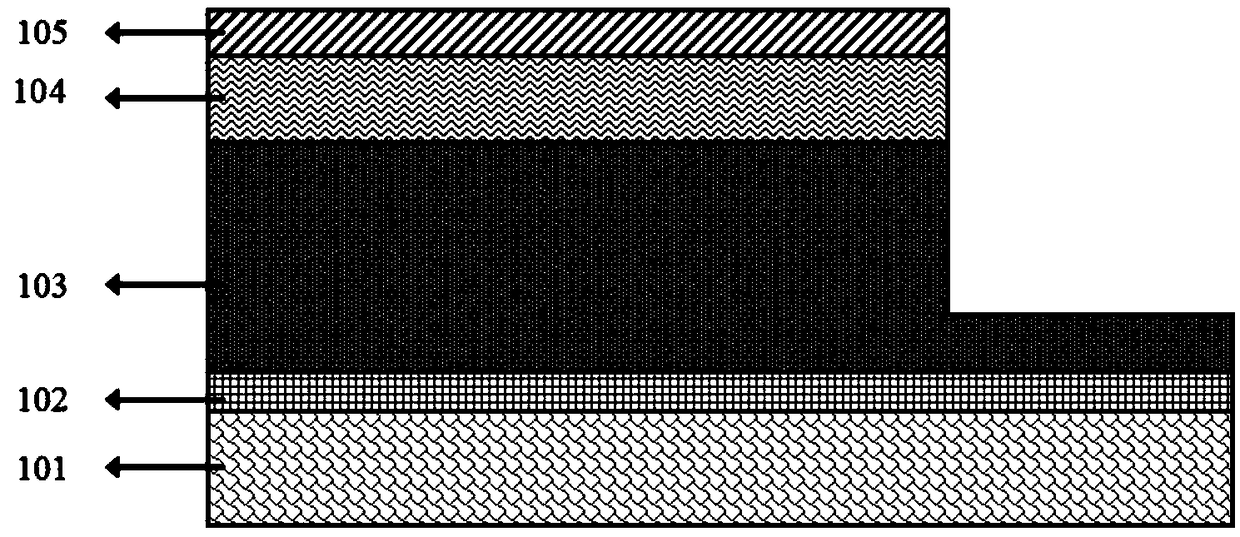

[0059] A method for preparing a chip epitaxial structure of a low-resistance LED of the present invention, the steps of the method are as follows:

[0060] In the first step, the substrate 101 is baked at a high temperature of 900°C to 1400°C in an MOCVD (metal organic compound chemical vapor deposition) or MBE (molecular beam epitaxy) reaction furnace to remove foreign matter attached to the substrate surface ;

[0061] The second step is to epitaxially grow a buffer layer 102 with a thickness of 10 to 50 nm on the surface of the substrate 101 treated in the first step in an MOCVD or MBE reactor, so as to filter dislocations and release stress caused by lattice mismatch;

[0062] The third step is to deposit an N-type semiconductor material layer 103 with a thickness of 1-5 μm on the buffer layer 102 obtained in the second step in an MOCVD or MBE reactor;

[0063] In the fourth step, in the MOCVD or MBE reaction furnace, epitaxially grow the multi-quantum well layer 104 on t...

Embodiment 1

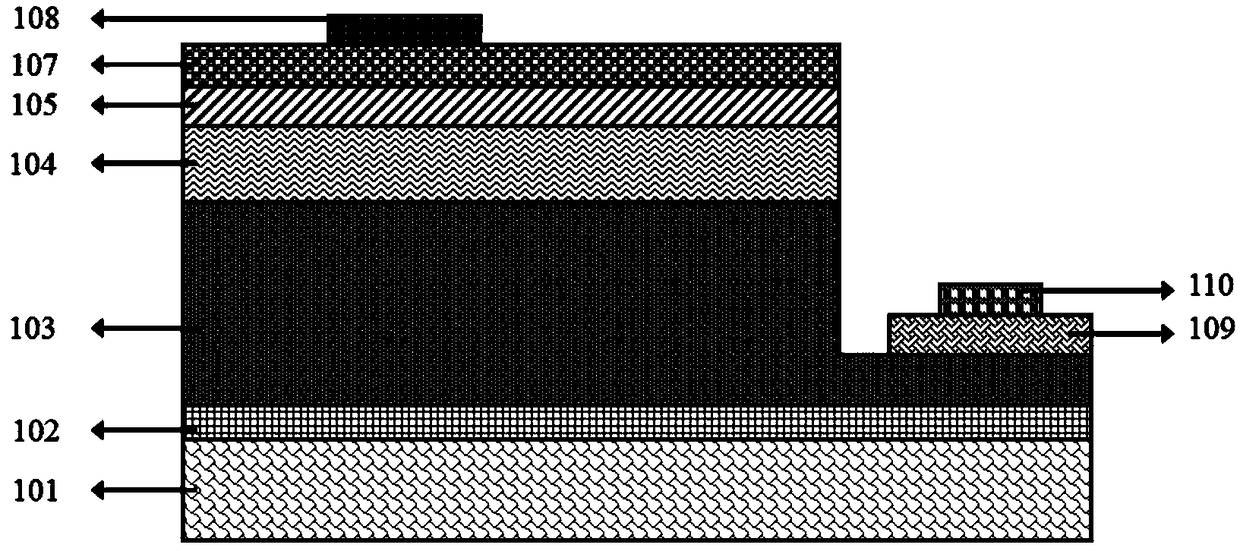

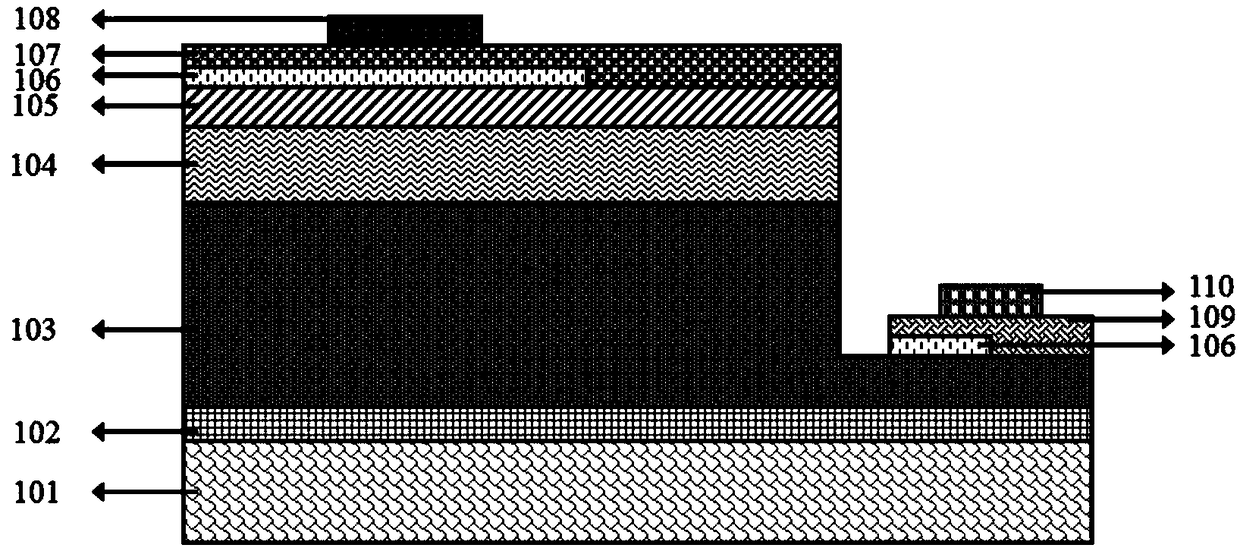

[0072] The present embodiment has a chip epitaxial structure of a low-resistance LED, and the epitaxial structure includes in sequence along the epitaxial growth direction: a substrate 101, a buffer layer 102, an N-type semiconductor material layer 103, a multi-quantum well layer 104, a P- Type semiconductor material layer 105, insulating layer 106, current spreading layer 107, N pole ohmic contact layer 109, P-type ohmic electrode 108 and N-type ohmic electrode 110, wherein the material used for the thickness of insulating layer 106 is SiO 2 , the thickness is 1 nm, the insulating layer 106 on the P-type semiconductor material layer 105 is a 1 / 4 ring, and the width of this ring is 200 μm, and the insulating layer 106 on the N-type semiconductor material layer 103 is a 1 / 2 ring, The ring has a width of 10 μm and is a patterned film structure.

[0073] Among the above, the substrate 101 is sapphire, which grows epitaxially along the [0001] direction; the material of the buffer ...

Embodiment 2

[0089] The components of the chip epitaxial structure of a low-resistance LED in this embodiment are the same as in Embodiment 1, except that the material of the buffer layer 102 is GaN with a thickness of 25nm; the material of the N-type semiconductor material layer 103 is GaN, The thickness is 3 μm; the structure of the multi-quantum well layer 104 is 3 periods of In 0.18 Ga 0.82 N / GaN layer, in which the thickness of the quantum barrier GaN is 10nm, and the quantum well In 0.18 Ga 0.82 The thickness of N is 3nm, and the forbidden band width of quantum barrier is 0.83eV larger than the forbidden band width of quantum well; The material of P-type semiconductor material layer 105 is GaN, and thickness is 60nm; The material of insulating layer 106 is Al 2 o 3 , the thickness is 1.5nm, the insulating layer 106 on the P-type semiconductor material layer 105 is a square, and the side length is 100 μm, and the insulating layer 106 on the N-type semiconductor material layer 103 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com