Nano-modified coating material and preparation method thereof

A coating material and nano-modification technology, applied in the field of nano-technology in coating materials, can solve problems such as influence and uncontrollable reaction, and achieve the effect of improving mechanical properties, improving salt spray resistance, and obvious toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

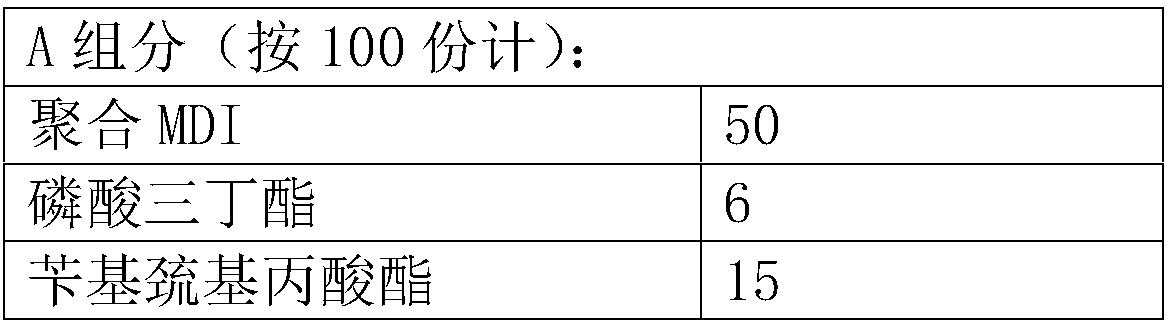

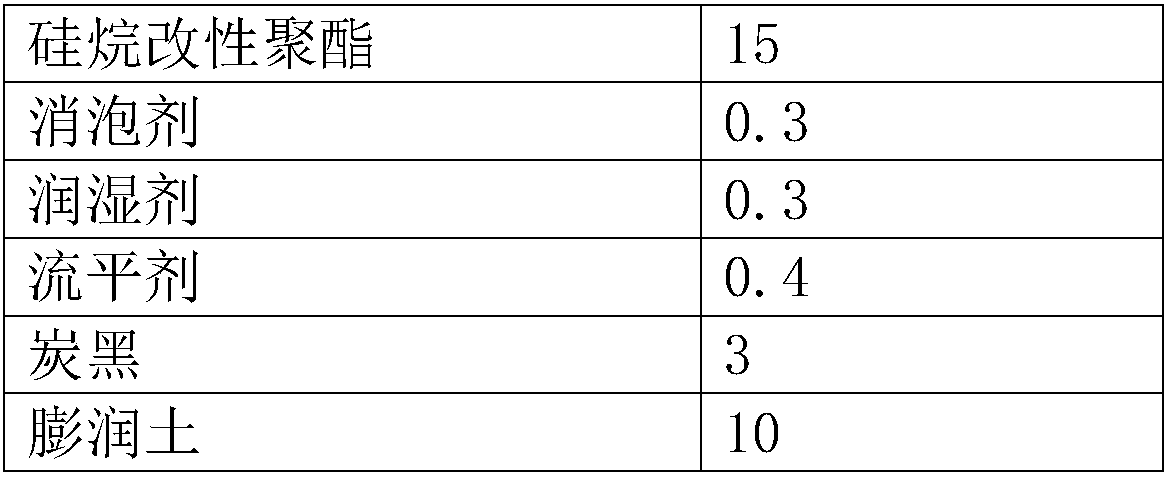

[0045] A polyurethane / polyurea material modified by inorganic nanoparticles, prepared according to the following ratio:

[0046]

[0047]

[0048]

[0049] Note: Defoamer is Tego 900

[0050] Leveling agent is Tego410

[0051] Wetting agent BYK 2151

[0052] The preparation method of the polyurethane / polyurea coating material modified by inorganic nanoparticles is as follows:

[0053] ① Add 50 parts of modified polymerized MDI to the dispersion kettle, and sequentially add 6 parts of tributyl phosphate, 15 parts of methacryloxyethyl phosphate, 15 parts of monofunctional acrylic phosphate polymer, and stir for 10 minutes;

[0054] ②Add 3 parts of carbon black and 10 parts of bentonite to the above slurry, and use 1000-2000r to disperse for 1-2 hours until the slurry is stable;

[0055] ③Add 0.3 part of wetting agent, 0.4 part of leveling agent, and 0.3 part of defoamer to the above stable slurry, stir for 10 minutes, and filter to obtain component A.

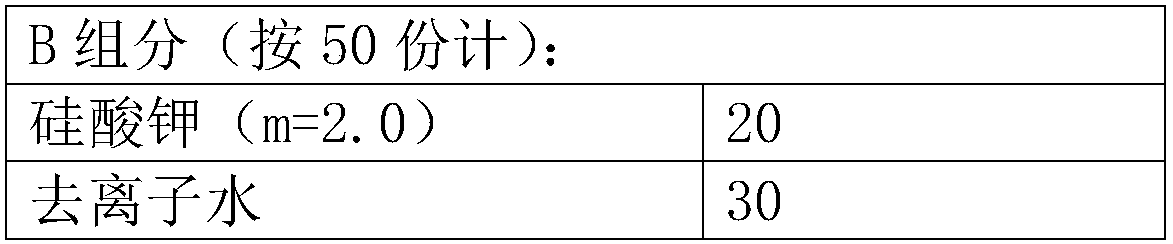

[0056] ④ Add 40 parts of potassium sil...

Embodiment 2-14

[0059] The phosphate ester mixture in the formulation of Example 1 was replaced as shown in Table 1, and the other compositions and ratios remained unchanged.

[0060] Table 1 Types of Functional Phosphate Mixtures in Examples

[0061]

[0062]

[0063] Note: Monomer ① is benzyl mercaptopropionate;

[0064] Monomer ② is ethylene glycol methacrylate phosphate;

[0065] Monomer ③ is methacryloyloxyethyl phosphate;

[0066] Polymer ① is silane modified polyester 928, Hengshui Songshan Chemical Co., Ltd.;

[0067] Polymer ②Polyester / silicon hybrid resin EVOK-343PP;

[0068] Polymer ③ is a bifunctional acrylic phosphate polymer SWR-150, Wafer Chemical Co., Ltd.;

[0069] Polymer ④ is a multifunctional acrylic phosphate polymer, SWR-151, Wafer Chemical Co., Ltd.;

[0070] Polymer ⑤ is a bifunctional epoxy modified polyester, SRE-6005-30, Shi Rui Co., Ltd.;

[0071] Polymer ⑥ is a multifunctional epoxy modified polyester, SRE-6005A Shi Rui Co., Ltd.;

Embodiment 10

[0073] A polyurethane / polyurea material modified by inorganic nanoparticles, prepared according to the following ratio:

[0074]

[0075] Note: Defoamer is Tego 900

[0076] The leveling agent is Tego410 plasticizer is mixed and matched

[0077] Wetting agent BYK 2151

[0078] The preparation method of the polyurethane / polyurea coating material modified by inorganic nanoparticles is as follows:

[0079] ① Add 50 parts of modified polymerized MDI to the dispersion kettle, and sequentially add 6 parts of tributyl phosphate, 8 parts of methacryloxyethyl phosphate, 22 parts of monofunctional acrylic phosphate polymer, and stir for 10 minutes;

[0080] ②Add 3 parts of carbon black and 10 parts of bentonite to the above slurry, and disperse at 1000-2000r for 1-2 hours until the slurry is stable;

[0081] ③Add 0.3 part of wetting agent, 0.4 part of leveling agent, and 0.3 part of defoaming agent to the above stable slurry, stir for 10 minutes, and filter to obtain component A.

[0082] ④ Add 40 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com