A method for preparing high-performance aluminum-based silicon carbide

A technology of aluminum-based silicon carbide and silicon carbide, applied in metal processing equipment, nanotechnology for materials and surface science, transportation and packaging, etc., can solve problems such as uneven distribution and uneven density distribution of green compacts, and achieve Excellent comprehensive performance, low production cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

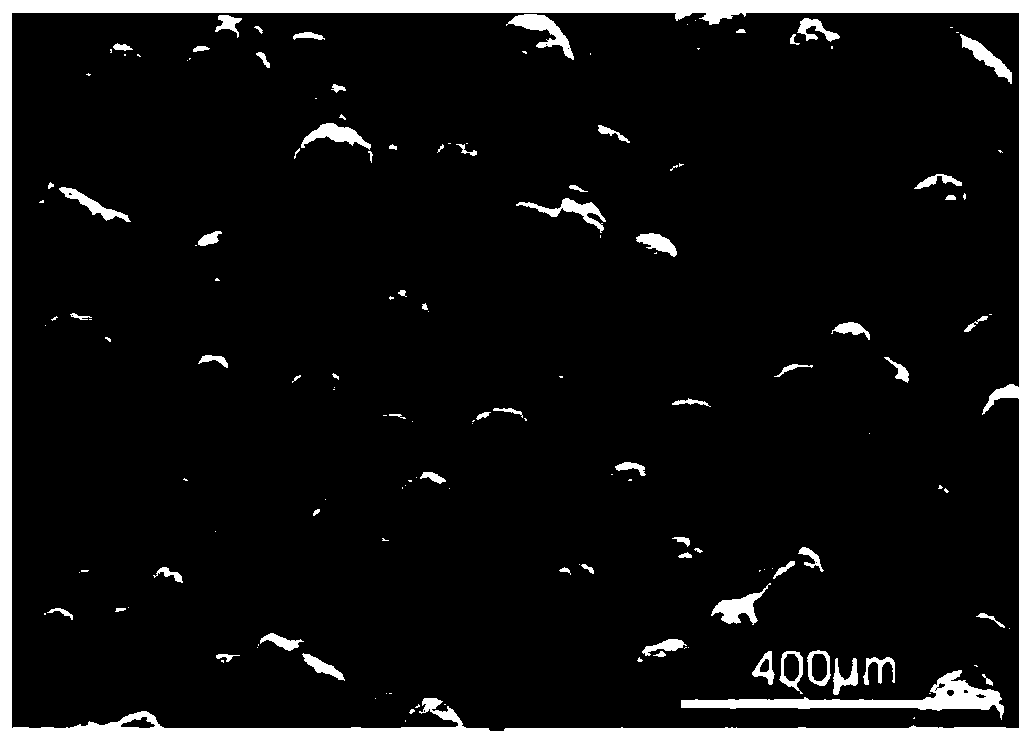

[0035] (1) 18g of phenolic resin and 1.8g of nickel nitrate were dissolved in 60ml of absolute ethanol and stirred, then added 60ml of tetraethyl orthosilicate; after the above solution was fully mixed, 5g of surfactant sodium lauryl sulfate was added, and then Add 10ml of oxalic acid for hydrolysis, and then add 4mL of methyltetramine to accelerate the gelation. After the gel is formed, it is aged for 22 hours to obtain silicon carbide powder. Put 10g of the prepared silicon carbide powder into a test tube, add 5ml of acetone, and disperse it by ultrasonication for 15 minutes, then add 2ml of coupling agent KH-550 (γ-aminopropyltriethoxysilane), and continue ultrasonication After 40 minutes, reflux in an oil bath at 85°C for 12 hours. The oil bath is made of silicone oil. After sufficient centrifugation, it is washed with acetone, dried and baked at 70°C to obtain surface-modified silicon carbide.

[0036] (2) Measure 300mL of distilled water into a 500mL three-neck flask, he...

Embodiment 2

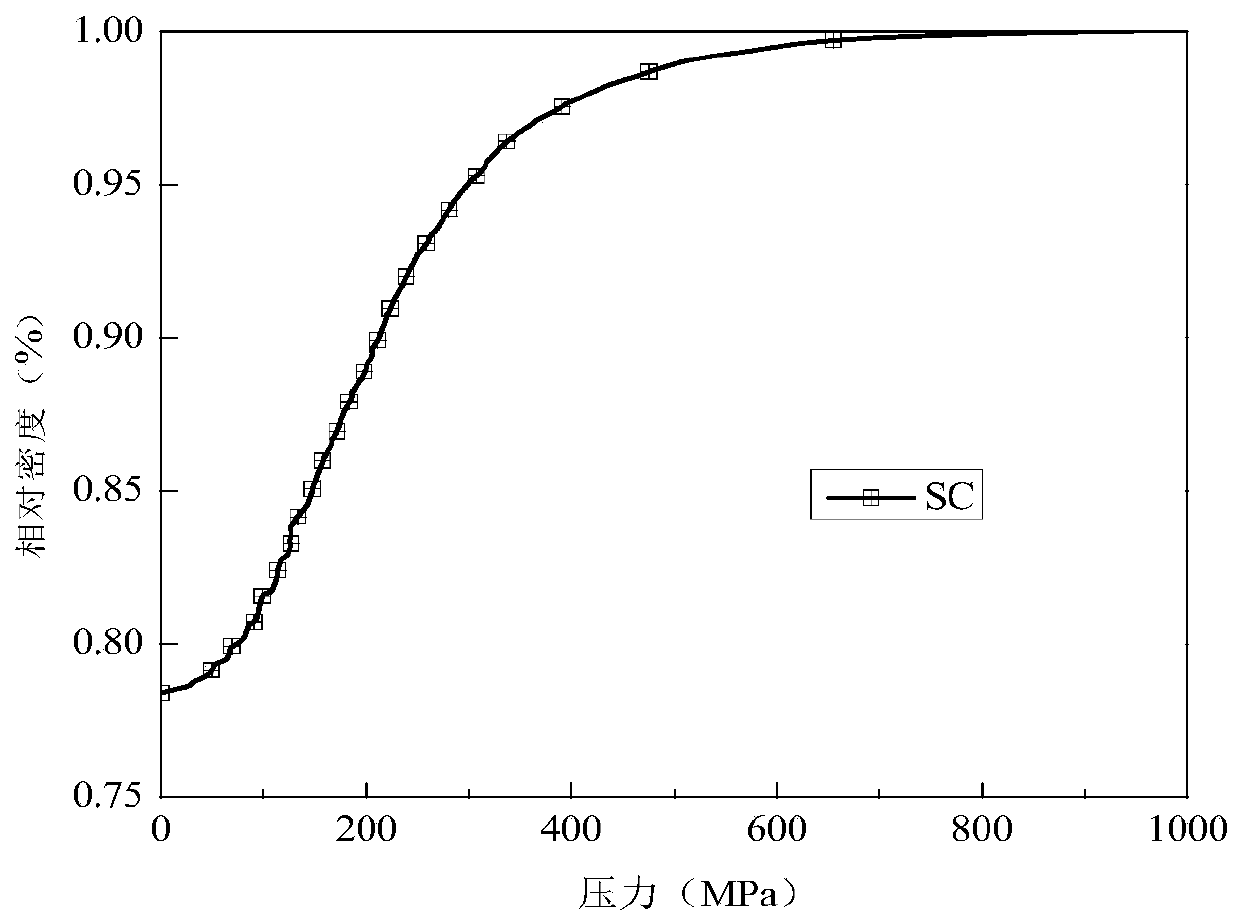

[0042] When embodiment 2Al and SiC content are different, the impact on compaction density and temperature

[0043] On the basis of Example 1, by controlling Al(C 3 h 7 O) 3 / HNO 3 The precipitation solution and the pH value can be used to obtain core-shell structure composite particles of aluminum nanoshells coated with silicon carbide with core (SiC) shell (Al) size ratios of 5:1, 5:2, and 2:1. During the reaction process, the more precipitation solution, the more Al ions in the solution. When pH3 h 7 O) 3 / HNO 3 The thickness of the shell is controlled by the precipitation solution and the pH value, thereby adjusting the size ratio of the core to the shell.

[0044] Aluminum-based silicon carbide particles with the same mass and particle size of core (SiC) shell (Al) size ratios of 5:1, 4:1, 5:2, and 2:1 were put into the mold, and then pressed at high speed. Press every 80MPa, the pressure range is 0-2000MPa, measure the relative density and the temperature of the ...

Embodiment 3

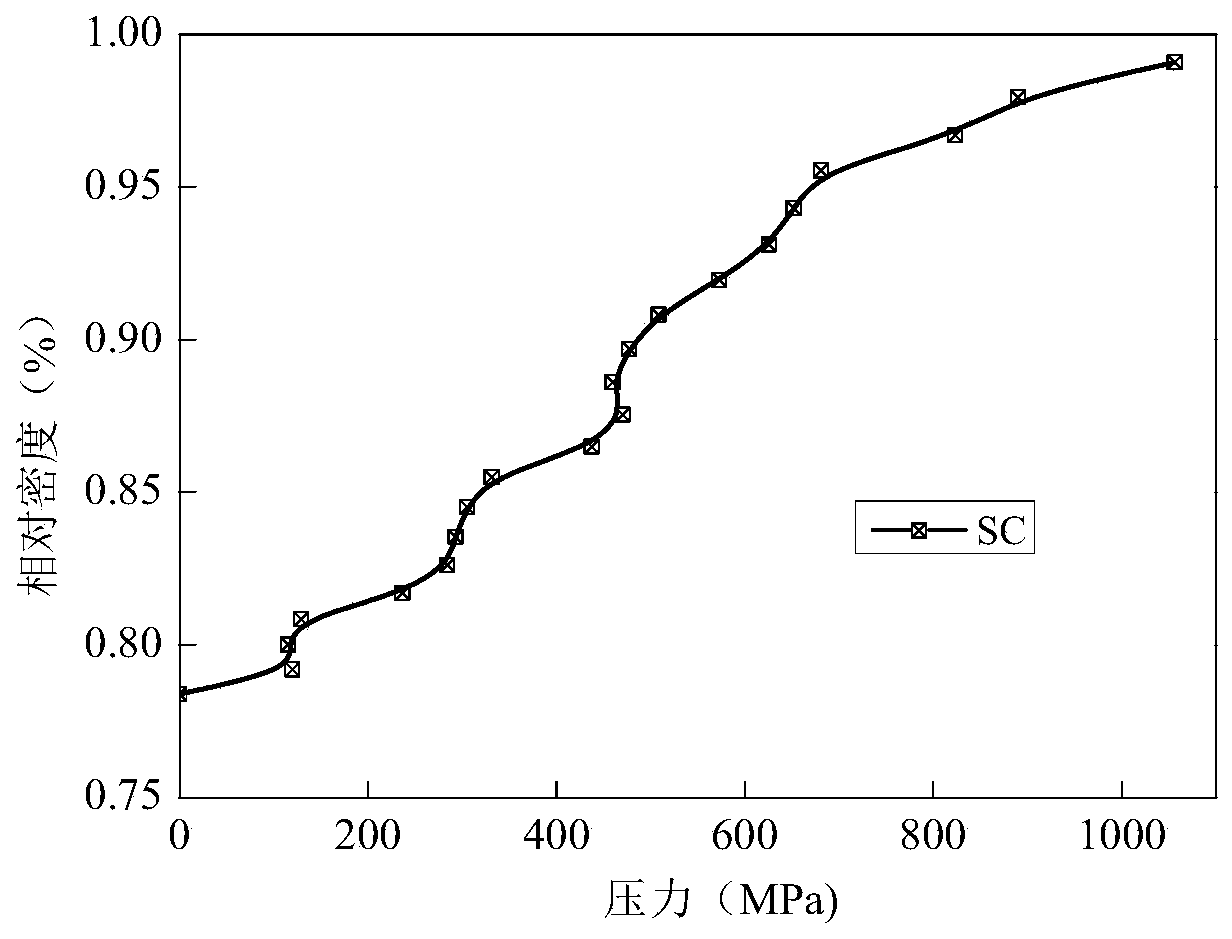

[0046] Embodiment 3 The impact of pressing speed on green compact density and temperature

[0047] Put the aluminum-based silicon carbide particles with the same mass and the same content and particle size into the mold, wherein the core (SiC) shell (Al) size ratio of the aluminum-based silicon carbide particles is 4:1, which can be prepared according to Example 1, and the hammerhead is controlled The speeds are 10m / s, 20m / s, 30m / s, 40m / s and 50m / s respectively, samples are taken every 100MPa, the pressure range is 0-2000MPa, and the influence of the pressing speed on the pressing process is observed. The result is as Figure 6 shown. It shows that the higher the pressing speed, the greater the temperature rise, but the compact density is relatively low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com