Fluorphlogopite glass ceramics from melting and casting tailings and preparation method thereof

A technology for fluorphlogopite and glass ceramics, which is applied in the field of smelting and casting tailings fluorphlogopite glass ceramics and its preparation, can solve the problems of limited utilization of gold/molybdenum tailings, difficulty in separation and purification, environmental pollution and the like, and achieves processability. Good, good mechanical properties, the effect of solving pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

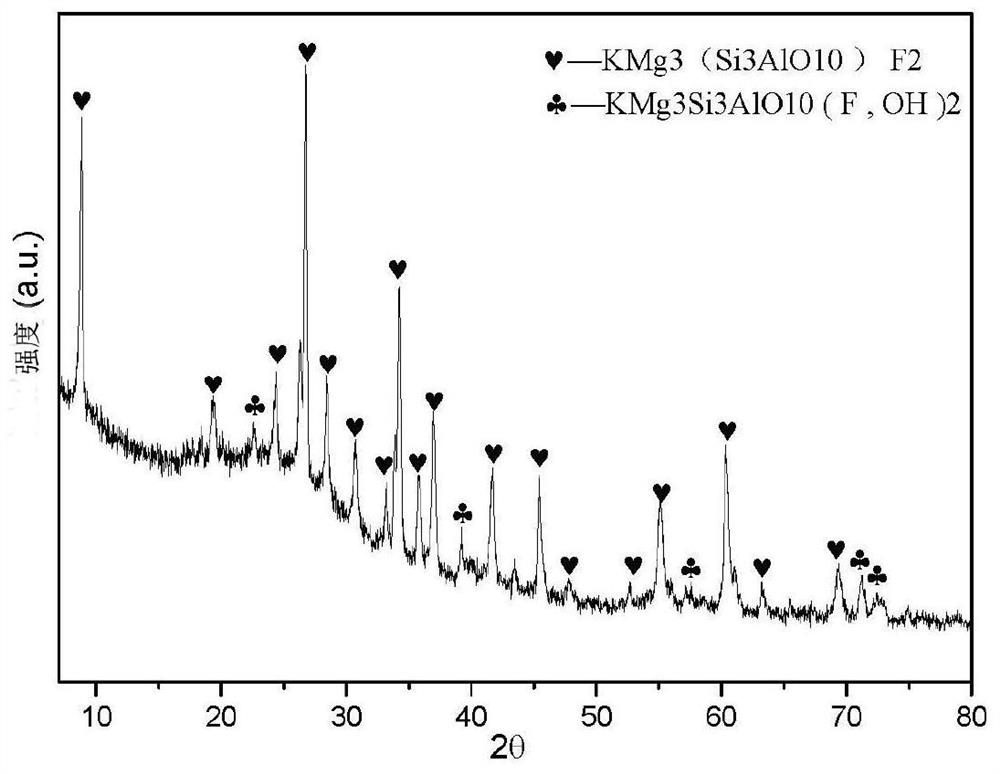

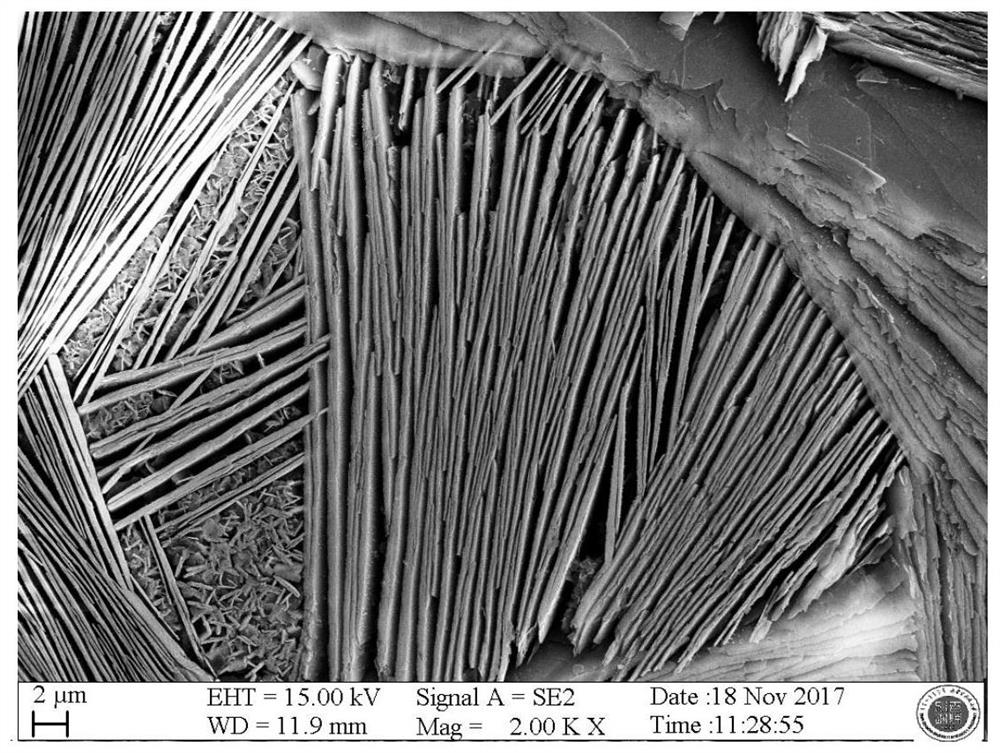

Embodiment 1

[0042] A fluorine phlogopite glass-ceramic glass-ceramic with casting tailings, which is composed of the following raw materials in weight percentage: 45% gold tailings, 22% silicon dioxide, 6% aluminum oxide, 5% magnesium oxide, 7% carbonic acid Potassium, 5% borax, 10% magnesium fluoride, the total amount of the above raw materials is 100%; additionally 1.5% chromium oxide and 0.5% zirconium oxide.

[0043] The preparation method of melting and casting tailings fluorphlogopite glass ceramics comprises the following steps:

[0044] (1) Take each raw material by weighing the raw material formula, mix evenly;

[0045](2) Put the uniformly mixed raw materials into the electric furnace, heat to 1400°C, keep it warm for 4 hours, make it melt and clarify, and obtain glass liquid;

[0046] (3) Casting the molten glass into a mold preheated to 500°C for molding, and then demoulding;

[0047] (4) The sample after demoulding is placed in an electric furnace and kept at 500°C for 3h f...

Embodiment 2

[0053] A fluorine phlogopite glass-ceramic glass-ceramic with casting tailings, which is composed of the following raw materials in weight percentage: 50% gold tailings, 18% silicon dioxide, 5% aluminum oxide, 6% magnesium oxide, 5% carbonic acid Potassium, 7% borax, 9% magnesium fluoride, the total amount of the above raw materials is 100%, and 2% chromium oxide and 2% titanium oxide of the total raw material amount are added.

[0054] The preparation method of melting and casting tailings fluorphlogopite glass ceramics comprises the following steps:

[0055] (1) Take each raw material by weighing the raw material formula, mix evenly;

[0056] (2) Add the homogeneously mixed raw materials into the electric furnace, heat to 1500°C, keep it warm for 2 hours, make it melt and clarify, and obtain molten glass;

[0057] (3) Casting molten glass into a mold preheated to 550°C for molding, and then demoulding;

[0058] (4) The sample after demoulding was placed in an electric furn...

Embodiment 3

[0064] A fluorine phlogopite glass-ceramic glass-ceramic with casting tailings, which is composed of the following raw materials in weight percent: 30% molybdenum tailings, 30% gold tailings, 12% silicon dioxide, 6% aluminum oxide, 4% Magnesium oxide, 5% potassium carbonate, 3% borax, 10% magnesium fluoride, the total amount of the above raw materials is 100%; plus 2% zirconia, 1% chromium oxide, and 1% titanium oxide .

[0065] The preparation method of melting and casting tailings fluorphlogopite glass ceramics comprises the following steps:

[0066] (1) Take each raw material by weighing the raw material formula, mix evenly;

[0067] (2) Add the homogeneously mixed raw materials into the electric furnace, heat to 1450°C, keep the temperature for 3 hours, make it melt and clarify, and obtain the molten glass;

[0068] (3) Casting the molten glass into a mold preheated to 600°C for molding, and then demoulding;

[0069] (4) The sample after demoulding was placed in an elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com