Anionic thermoviscosifying water-soluble polymer as well as preparation method and application thereof

A water-soluble polymer, anionic technology, applied in drilling compositions, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high preparation and application cost, difficult post-processing, long dissolution time, etc. Achieve the effect of reducing application cost, improving production efficiency, and reducing dissolution time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-18

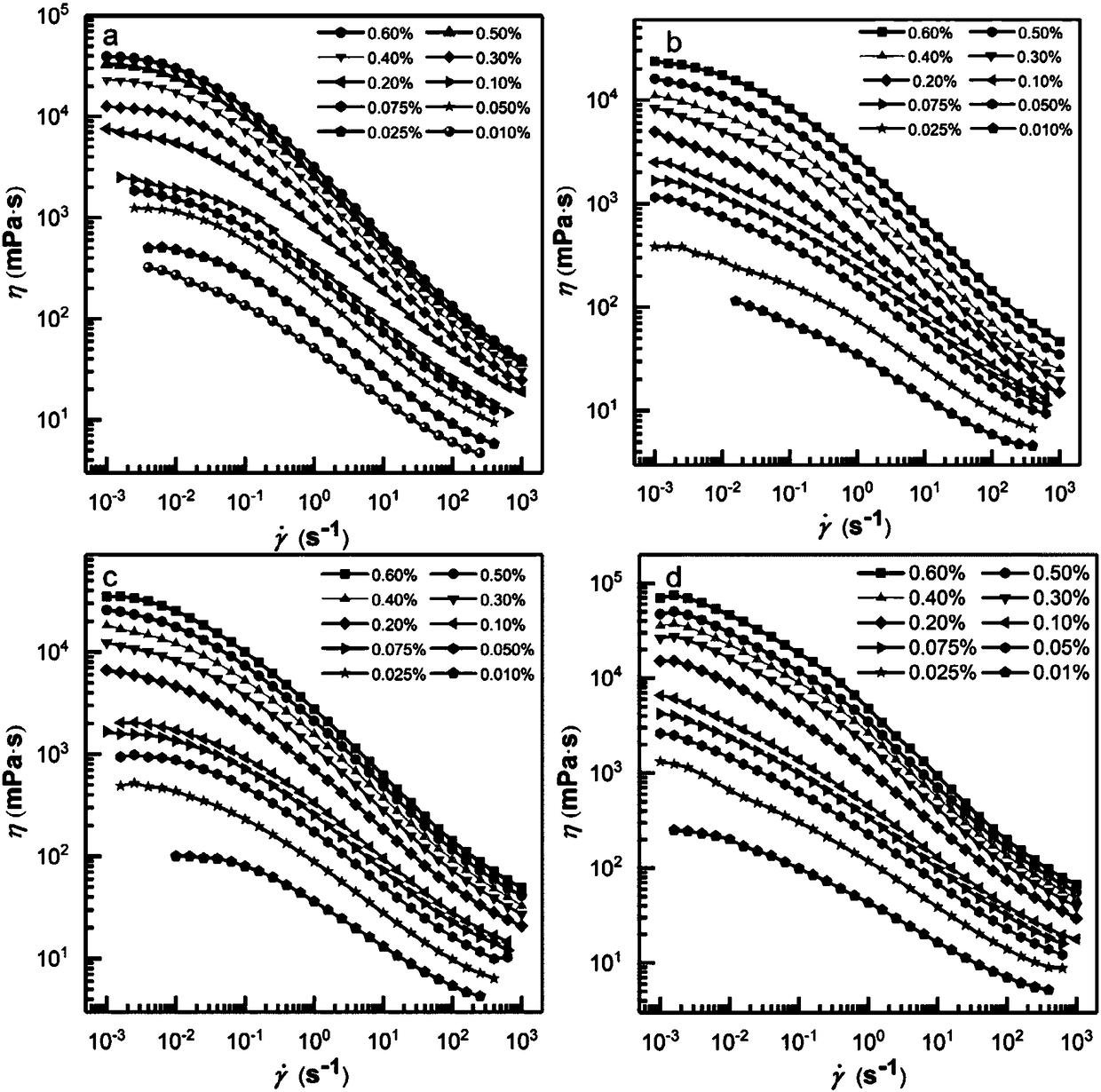

[0064] The following table explores the optimal inverse emulsion ratio from the four aspects of emulsifier type, oil-water ratio, monomer ratio, and the presence or absence of NaAA, so as to obtain the optimal anionic thermal tackifying polymer.

[0065] Table 1 Effect of emulsifier type on emulsion state

[0066]

[0067]

[0068] a × means no inverse emulsion was prepared, √ means inverse emulsion was prepared.

[0069] Table 2 Effect of oil-water ratio on emulsion state

[0070]

[0071] a × means no inverse emulsion was prepared, √ means inverse emulsion was prepared.

[0072] Table 3 Effect of monomer ratio on polymer properties

[0073]

[0074]

[0075] a × represents that the prepared polymer dry powder has no thermal viscosity-increasing property, and √ represents that the prepared polymer dry powder has thermal viscosity-increasing property.

[0076] Table 4 Effect of the presence or absence of NaAA monomer on polymer properties

[0077]

[0...

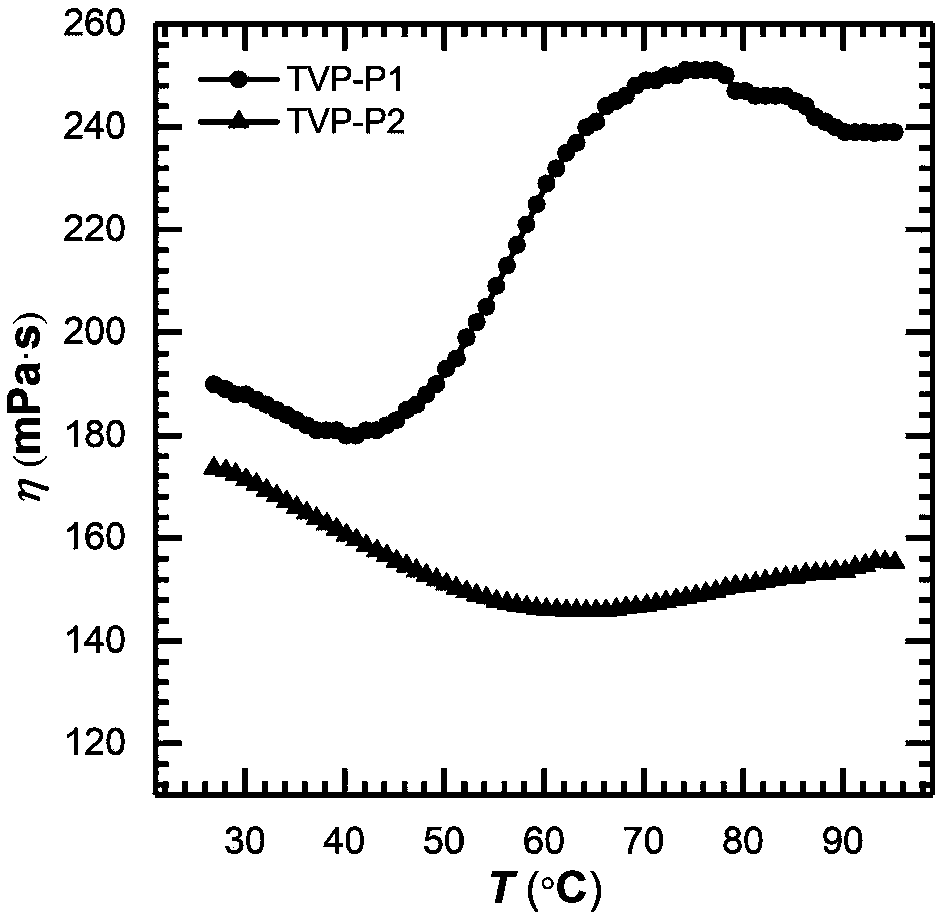

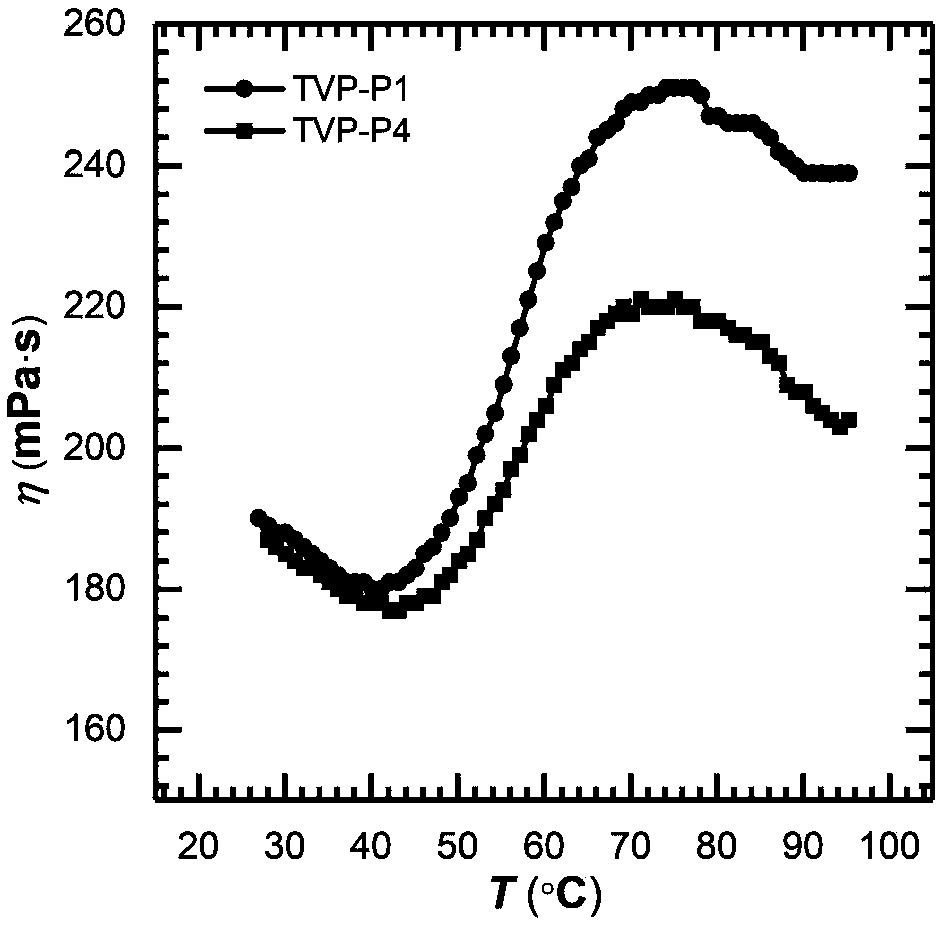

Embodiment 19

[0081] Dissolve 31.7% (w / w, the same below) of acrylamide, 9.5% of sodium acrylate, 8.6% of F127, and 5.0% of sodium chloride in 45.2% of deionized water, adjust the pH to 7.0, and prepare water Mutually. Dissolve 14.0% emulsifier HB246 in 86.0% mineral oil, heat to 50°C to dissolve, then add the oil phase and water phase to the emulsifier in sequence according to the ratio of mass ratio oil phase:water phase=4.5:5.5, Stir well and emulsify. After the emulsification is completed, transfer it to a 250mL four-neck flask equipped with stirring, nitrogen tube, and digital display thermometer, raise the temperature to 45°C in a water bath, and after passing nitrogen for a certain period of time, add the initiator AIBN, and start the polymerization. After the thermometer shows that the temperature rise is over, keep warm for 2 hours. The inverse emulsion ETVP-P1 of the anionic heat-thickening water-soluble polymer is obtained, and the obtained inverse emulsion is precipitated, was...

Embodiment 20

[0083] Dissolve 31.7% (w / w, the same below) of acrylamide, 9.5% of sodium acrylate, 8.6% of F108, and 5.0% of sodium chloride in 45.2% of deionized water, adjust the pH to 7.0, and prepare water Mutually. Dissolve 14.0% emulsifier HB246 in 86.0% mineral oil, heat to 45°C to dissolve, then add the oil phase and water phase to the emulsifier in sequence according to the ratio of mass ratio oil phase: water phase = 4.5:5.5, Stir well and emulsify. After the emulsification is completed, transfer it to a 250mL four-neck flask equipped with stirring, nitrogen tube, and digital display thermometer, raise the temperature to 45°C in a water bath, and after passing nitrogen for a certain period of time, add the initiator AIBN, and start the polymerization. After the thermometer shows that the temperature rise is over, keep warm for 2 hours. The inverse emulsion ETVP-P2 of the anionic heat-thickening water-soluble polymer is obtained, and the obtained inverse emulsion is precipitated, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com