Fluorine-containing prepolymer modified waterborne epoxy (meth)acrylate composite UV curing coating and its preparation and application

A water-based epoxy and acrylate technology, which is applied in the field of polymer coatings, can solve the problems of lower coating body performance, difficult migration of fluorine-containing groups, and opaque materials, and achieve good coating adaptability, low viscosity, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

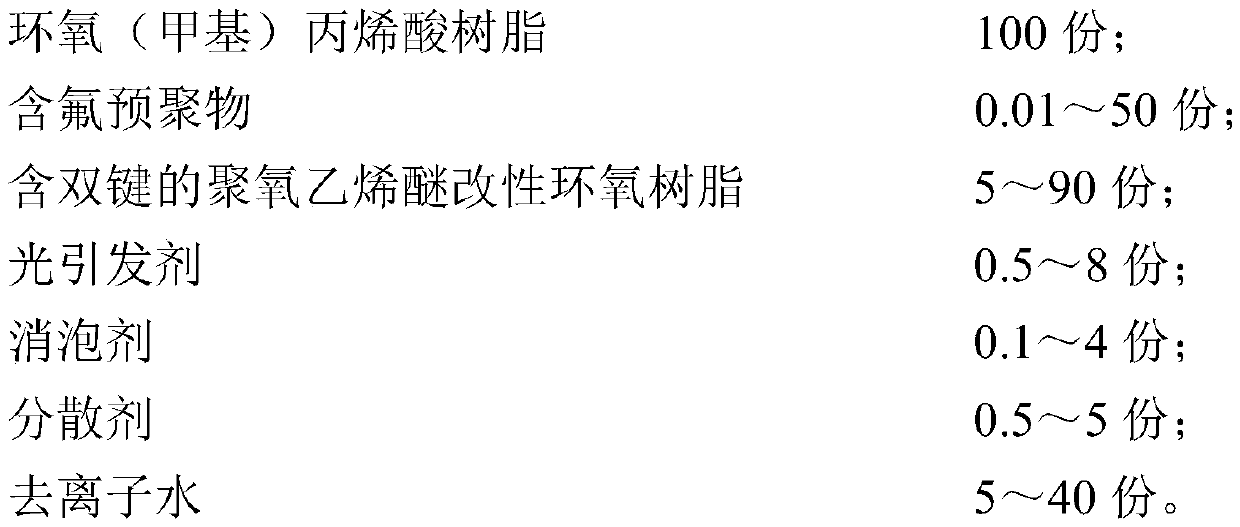

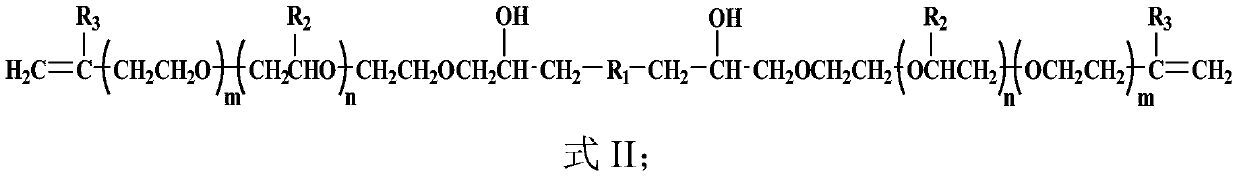

Method used

Image

Examples

Embodiment 1

[0064] (1) Preparation of epoxy methacrylate resin: 100 parts by mass of bisphenol A type epoxy resin (epoxy value 0.51) is added in the reactor that reflux condenser, dropping funnel, thermometer and stirrer are housed, Heat and stir to 80°C, then add 2 parts by mass of tetrabutylammonium bromide, 0.8 parts by mass of hydroquinone and 50 parts by mass of methacrylic acid, raise the temperature to 110°C, and react for 4 hours to obtain epoxy methacrylate resin.

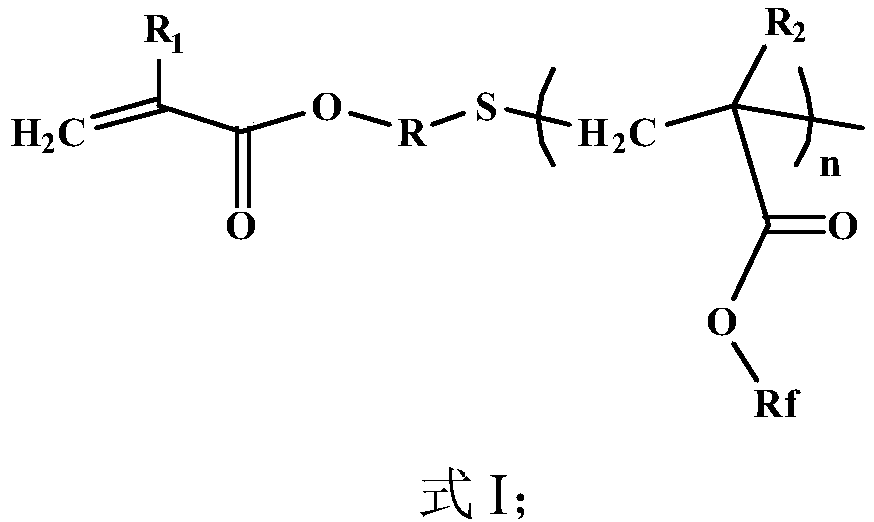

[0065] (2) Preparation of fluorine-containing prepolymer: add 30 parts by mass of methyl perfluorocyclohexyl acrylate and 55 parts by mass of dioxane into a container, heat up to 80° C., add 1 part by mass of 6-mercaptohexanol, pass 0.3 parts by mass of benzoyl oxide, stirred and reacted for 9 hours to obtain a hydroxyl-terminated fluorine-containing prepolymer solution; the temperature was cooled to 0°C in an ice bath, and 1.8 parts by mass of triethylamine and 1.5 parts by mass of acryloyl chloride were added to the...

Embodiment 2

[0069] (1) Preparation of epoxy acrylate resin: add 100 parts by mass of bisphenol A type epoxy resin (epoxy value 0.51) into the reactor equipped with reflux condenser, dropping funnel, thermometer and stirrer, heat and stir to 75°C, then add 1.5 parts by mass of tetrabutylammonium bromide, 0.5 parts by mass of hydroquinone and 40 parts by mass of acrylic acid, raise the temperature to 105°C, and react for 4 hours to obtain an epoxy acrylate resin.

[0070] (2) Preparation of fluorine-containing prepolymer: Add 30 parts by mass of 1H, 1H-perfluorooctyl methacrylate and 55 parts by mass of N,N-dimethylformamide in a container, heat up to 90°C, Add 3 parts by mass of 3-mercapto-1-hexanol and 0.4 parts by mass of azobisisobutyronitrile, stir and react for 8 hours to obtain a hydroxyl-terminated fluorine-containing prepolymer solution; 4 parts by mass of acryloyl chloride were added to the hydroxyl-terminated fluorine-containing prepolymer solution, stirred for 8 hours, and the f...

Embodiment 3

[0074] (1) Preparation of epoxy acrylate resin: 100 parts by mass of resorcinol bisglycidyl ether type epoxy resin (epoxy value 0.85) is added to the reaction that reflux condenser, dropping funnel, thermometer and stirrer are housed In a container, heat and stir to 78°C, then add 0.08 parts by mass of tetrabutylammonium bromide, 1.5 parts by mass of hydroquinone and 50 parts by mass of acrylic acid, raise the temperature to 108°C, and react for 2.5 hours to obtain epoxy acrylate resin .

[0075] (2) Preparation of fluorine-containing prepolymer: Add 40 parts by mass of heptadecanyl methacrylate and 80 parts by mass of ethyl acetate in a container, heat up to 78°C, add 1.2 parts by mass of 3-mercapto-1-propanol parts, 0.3 parts by mass of cumene peroxide, stirred and reacted for 9 hours to obtain a fluorine-containing prepolymer solution with terminal hydroxyl groups; cooled to 0°C in an ice bath, 2.2 parts by mass of triethylamine and 2 parts by mass of methacryloyl chloride ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com