A kind of positive electrode material of potassium ion battery based on nickel-manganese binary oxide and preparation method thereof

A binary oxide, battery cathode technology, applied in nickel compounds, battery electrodes, secondary batteries, etc., can solve the problems of poor cycle performance, low energy density, poor operation controllability, etc. The effect of high controllability and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 0.005mol nickel acetate, 0.005mol manganese acetate and 0.013mol potassium acetate (5% excess) in 20mL of ethanol and deionized water with a volume ratio of 1:1;

[0032] (2) Dissolve 1.299g of acetic acid in 10mL of ethanol and deionized water with a volume ratio of 1:2;

[0033] (3) Add the metal salt solution dropwise into the acetic acid solution at a rate of 1-2 drops / s, and then stir for 6 hours at a rate of 200 rpm;

[0034] (4) heating the obtained mixed solution at 60° C. under vacuum until the water is evaporated to dryness to obtain a powder;

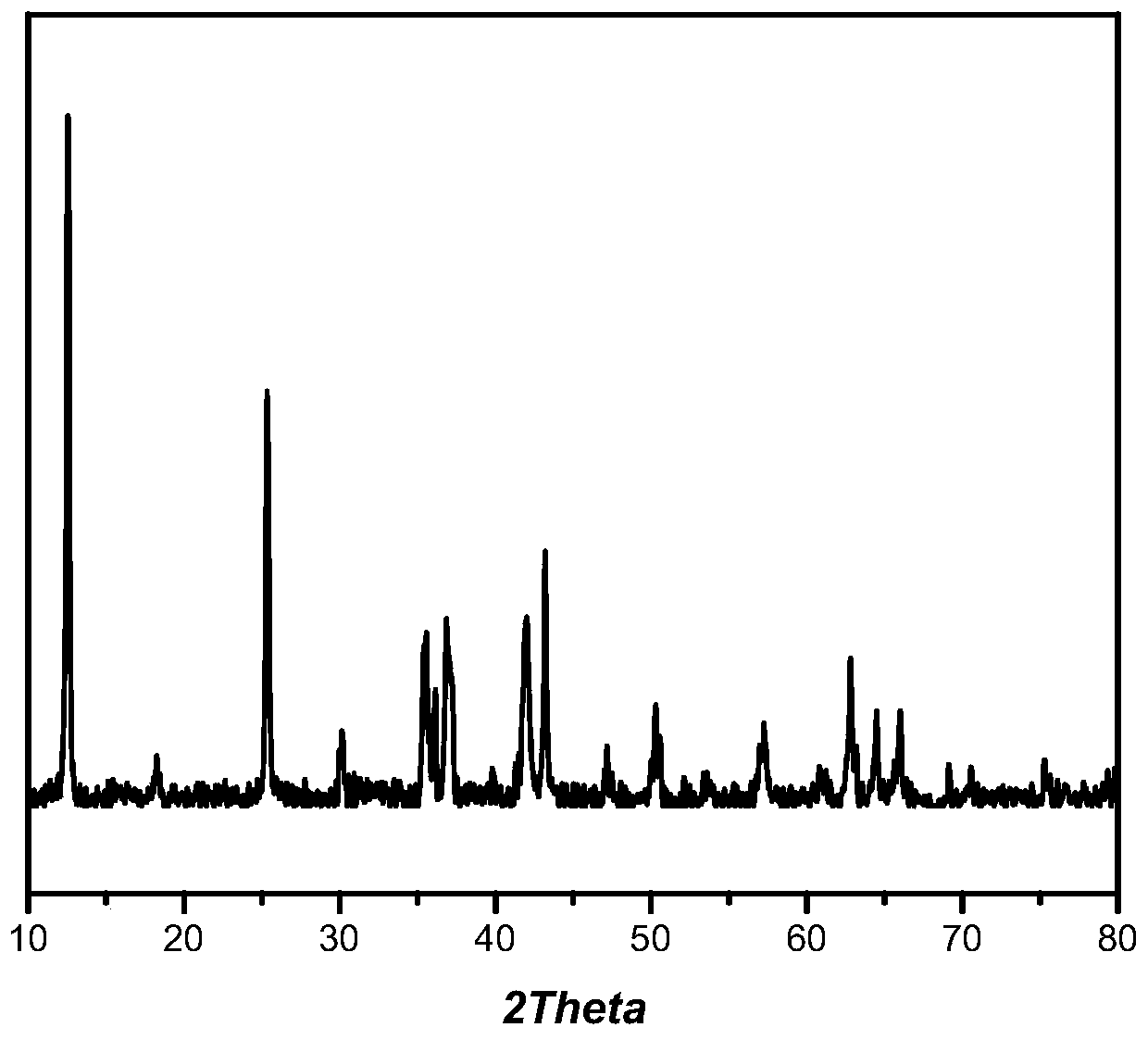

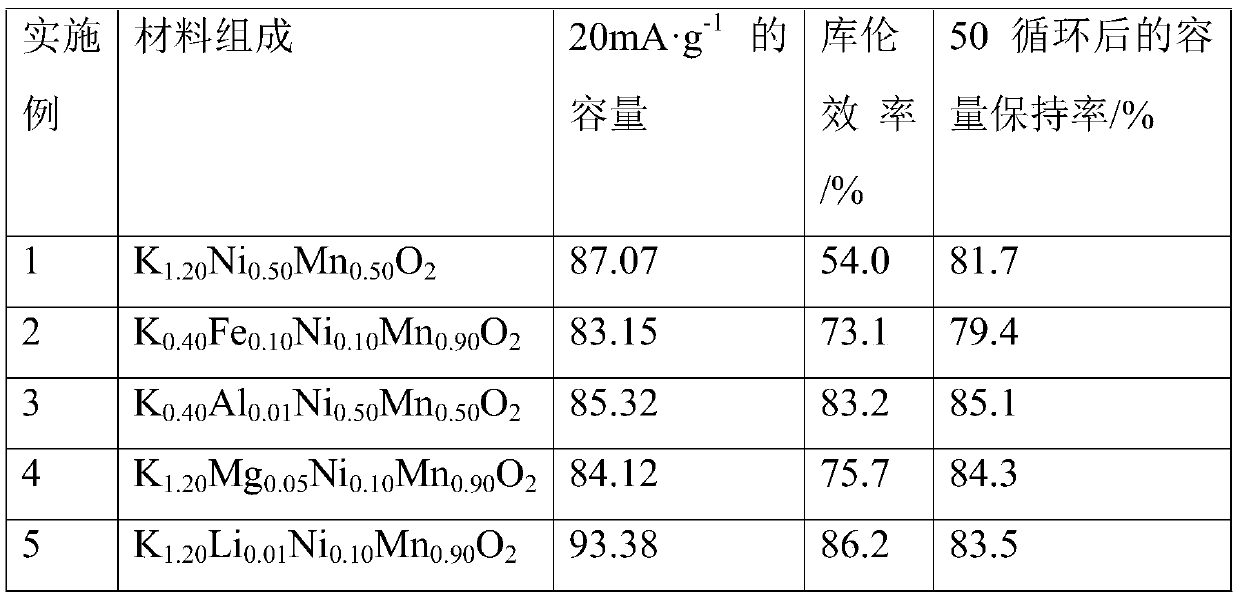

[0035] (5) The obtained powder was pre-sintered at 300°C in an air atmosphere (the heating rate was 3°C / min), then cooled to room temperature and then ground, and then calcined at 700°C for 8 hours (the heating rate was 5°C / min) to obtain potassium ions Battery cathode material K 1.20 Ni 0.50 mn 0.50 o 2 .

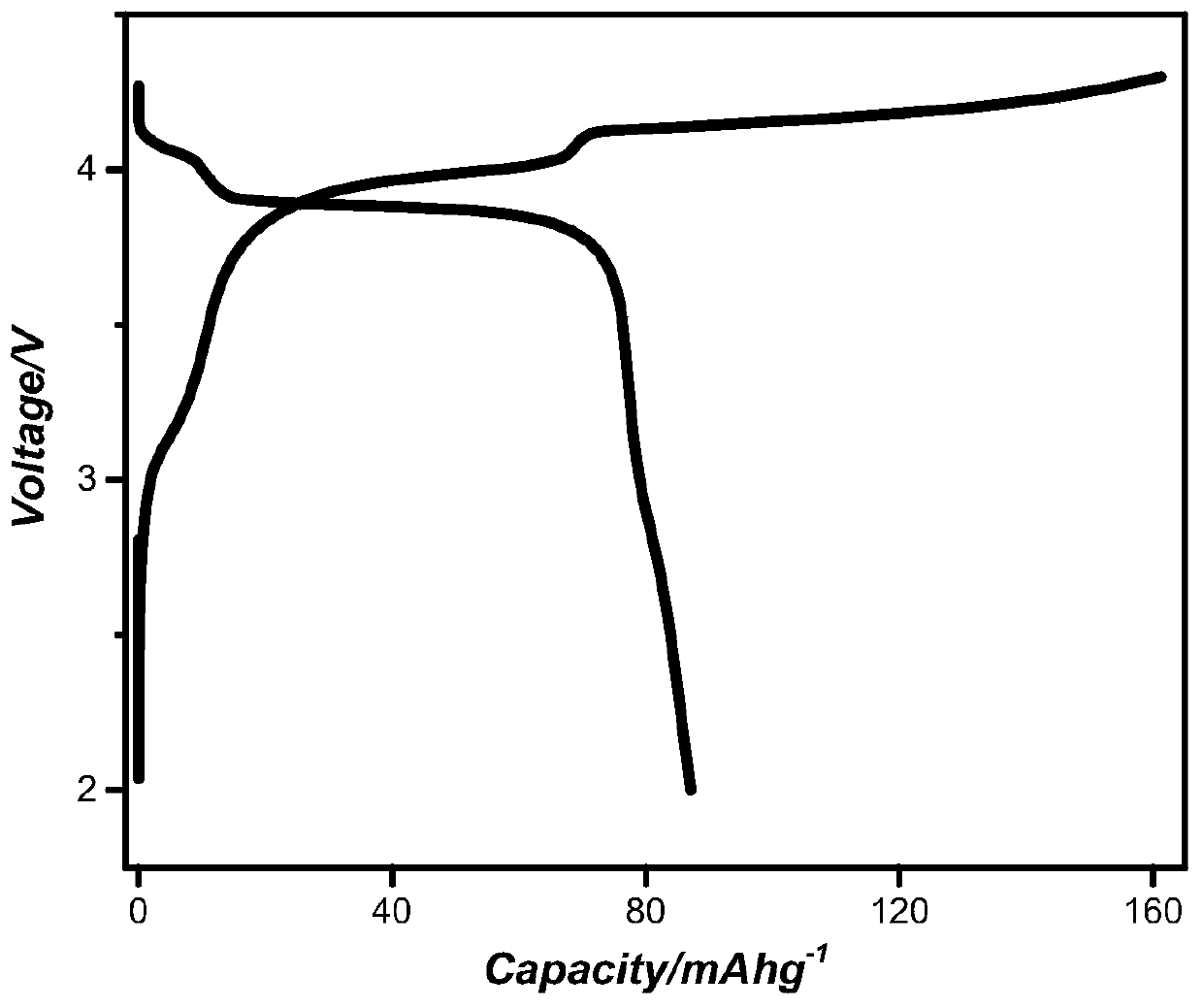

[0036] The assembly steps of the button battery: mix the positive electrode material with the...

Embodiment 2

[0041] (1) Dissolve 0.001mol nickel nitrate, 0.009mol manganese nitrate, 0.004mol potassium hydroxide (5% excess) and 0.001mol ferrous nitrate in 50mL of ethylene glycol and deionized water with a volume ratio of 1:4;

[0042] (2) 1.458g of oxalic acid was dissolved in 40mL of ethylene glycol and deionized water with a volume ratio of 1:6;

[0043] (3) Add the oxalic acid solution dropwise to the metal salt solution at a rate of 1-2 drops / s, and then stir at a rate of 500 rpm for 12 hours;

[0044] (4) Heat the obtained mixed solution at 120°C until the water is evaporated to dryness to obtain a powder;

[0045] (5) The obtained powder was pre-sintered at 500°C in an air atmosphere (heating rate of 5°C / min), cooled to room temperature and then ground, and roasted at 1000°C for 20h (heating rate of 3°C / min) to obtain a positive electrode for a potassium ion battery Material K 0.40 Fe 0.10 Ni 0.10 mn 0.90 o 2 .

[0046] The basic properties of the materials are shown in T...

Embodiment 3

[0048] In addition to using 0.004mol potassium carbonate to replace 0.013mol potassium acetate, 0.0005mol aluminum chloride to replace ferrous nitrate, nickel sulfate and manganese sulfate to replace nickel nitrate and manganese nitrate in equal moles, acetone to replace ethanol, and citric acid to replace acetic acid, other ingredients Use and preparation method are exactly the same as example 2, prepare positive electrode material K 0.40 Al 0.01 Ni 0.50 mn 0.50 o 2 .

[0049] The basic properties of the materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com