Green environment-friendly biomass particle fuel and preparation method thereof

A biomass particle, green and environmental protection technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of reduced fuel utilization rate and combustion efficiency, insufficient combustion, flue gas corrosion, etc., and achieve fuel processing performance and equipment power. Loss improvement, improved ash fusion, and reduced vapor volatilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

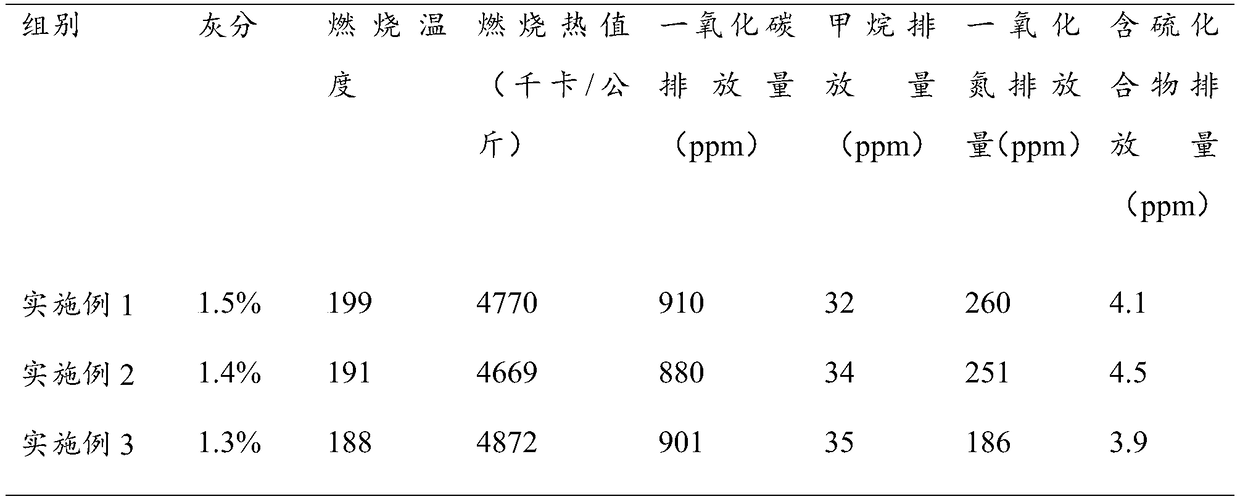

Examples

Embodiment 1

[0016] The preparation of embodiment 1 biomass particle fuel

[0017] A green and environment-friendly biomass pellet fuel is composed of the following raw materials in parts by weight: 60 parts of corn straw, 55 parts of rice straw, 15 parts of waste paper pulp, 5 parts of magnesium oxide, 4 parts of sodium hydroxide, 3 parts of aluminum oxide, 4 parts of kaolin, 5 parts of ammonium sulfate, 5 parts of milk of lime or carbide slag.

[0018] The preparation method of described biomass fuel particle, comprises the following steps:

[0019] Step 1. After drying, pulverizing, mixing, and pressing the above-mentioned portions of corn stalks and rice stalks respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use. The drying temperature is 90-120°C ;

[0020] Step 2, grinding waste paper pulp, magnesium oxide, aluminum oxide, kaolin, ammonium sulfate, milk of lime or carbide slag for 30-40 minutes, and spray dry...

Embodiment 2

[0022] Embodiment 2: the preparation of biomass particle fuel

[0023] A green and environment-friendly biomass pellet fuel is composed of the following raw materials in parts by weight: 65 parts of corn straw, 60 parts of rice straw, 20 parts of waste paper pulp, 7 parts of magnesium oxide, 6 parts of sodium hydroxide, 5 parts of aluminum oxide, 6 parts of kaolin, 7 parts of ammonium sulfate, 10 parts of milk of lime or carbide slag.

[0024] The preparation method of described biomass fuel particle, comprises the following steps:

[0025] Step 1. After drying, pulverizing, mixing, and pressing the above-mentioned portions of corn stalks and rice stalks respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use. The drying temperature is 90-120°C ;

[0026] Step 2, grinding waste paper pulp, magnesium oxide, aluminum oxide, kaolin, ammonium sulfate, milk of lime or carbide slag for 30-40 minutes, and spray d...

Embodiment 3

[0028] Embodiment 3: the preparation of biomass particle fuel

[0029] A green and environment-friendly biomass pellet fuel is composed of the following raw materials in parts by weight: 62 parts of corn stalks, 58 parts of rice stalks, 18 parts of waste paper pulp, 6 parts of magnesium oxide, 5 parts of sodium hydroxide, 4 parts of aluminum oxide, 5 parts of kaolin, 6 parts of ammonium sulfate, 8 parts of milk of lime or carbide slag.

[0030] The preparation method of described biomass fuel particle, comprises the following steps:

[0031] Step 1. After drying, pulverizing, mixing, and pressing the above-mentioned portions of corn stalks and rice stalks respectively, continue the pyrolysis and gasification reaction, and after cooling, crush them into powder again for later use. The drying temperature is 90-120°C ;

[0032] Step 2, grinding waste paper pulp, magnesium oxide, aluminum oxide, kaolin, ammonium sulfate, milk of lime or carbide slag for 30-40 minutes, and spray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com