A kind of preparation method of cobalt sulfide/carbon nano catalyst of rechargeable zinc-air battery

A carbon nano and cobalt sulfide technology, applied in the field of nano materials, can solve the problems of poor reversibility and poor stability of precious metals, and achieve the effects of simple preparation process, improved electrocatalytic properties, and reduced energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Weigh zinc nitrate and cobalt nitrate according to the molar ratio of zinc nitrate and cobalt nitrate being 7:3 (5.1 moles in total) and dissolve them in 80ml of methanol solution until they dissolve evenly (the color is red at this time); Dissolve 3.7 grams of methylimidazole in 80 ml of methanol, and wait until it dissolves evenly. The methanol solution containing metal ions zinc and cobalt and the methanol solution of organic dimethylimidazole were mechanically mixed together (the color was blue at this time), stirred with a magnet at room temperature for 24 hours, and the mixed solution gradually became cloudy from clear. Stop stirring after 24 hours, let stand for a period of time, there is a blue precipitate at the bottom of the beaker, and the color of the precipitate becomes lighter with the increase of zinc ions. The bottom precipitate was centrifuged and dried to obtain the precursor. According to the mass ratio of the precursor and the sulfur powder is 20:1,...

Embodiment 2

[0045]Weigh zinc nitrate and cobalt nitrate according to the molar ratio of zinc and cobalt as 4:1 (2 moles in total), and dissolve them in 8 grams of deionized water, and weigh 22.7 grams of dimethylimidazole and dissolve them in 80 grams of deionized water , and the aqueous solution of the above metal ions and the aqueous solution of organic ligand dimethylimidazole were mechanically mixed and magnetically stirred for 12 hours, centrifuged, and dried in an oven at 60 degrees to obtain a precursor. Weigh it according to the ratio of 10:1 of the mass of precursor and sulfur powder and put it in the roasting crucible, pass high-purity nitrogen gas, use the program to raise the temperature to 850 degrees, keep it for 150 minutes, and then carry out the program at 10 degrees per minute Cool down, take out the sample when the temperature of the tube furnace drops to room temperature, treat it with a hydrochloric acid solution with a concentration of 1.0 molar, soak it for 5 hours, ...

Embodiment 3

[0047] The composite material prepared in Example 1 was tested.

[0048] The powder diffraction pattern of cobalt sulfide / carbon nanocomposite is characterized by MiniFlex II powder diffractometer;

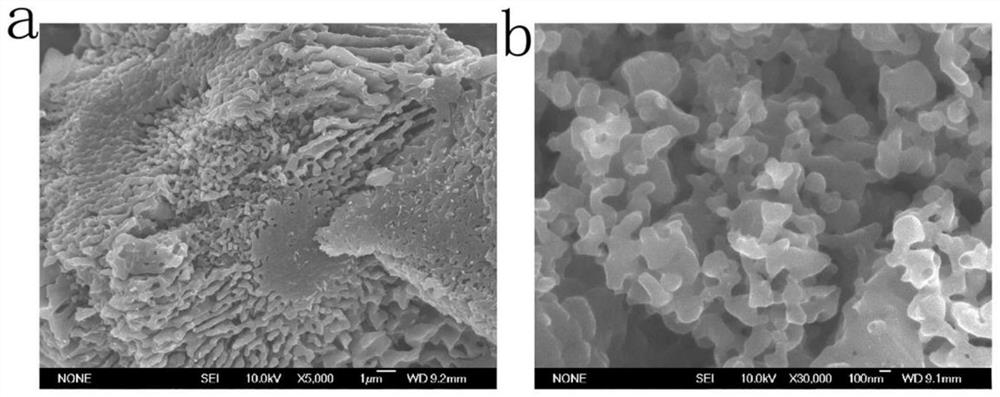

[0049] The scanning electron microscope image of the cobalt sulfide / carbon nanocomposite is characterized by a JSM-6700 scanning electron microscope;

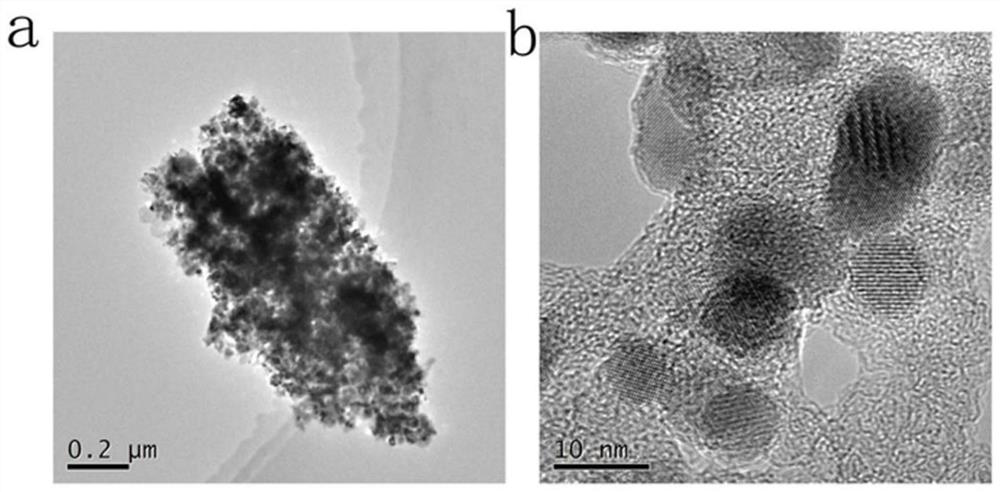

[0050] The transmission electron microscope image of the cobalt sulfide / carbon nanocomposite was characterized by a Tecnai G2F20 transmission electron microscope;

[0051] The nitrogen isotherm adsorption curve analysis of cobalt sulfide / carbon nanocomposites is characterized by ASAP2020M adsorption instrument;

[0052] The battery data of the cobalt sulfide / carbon nanocomposite is obtained through the blue point battery test system.

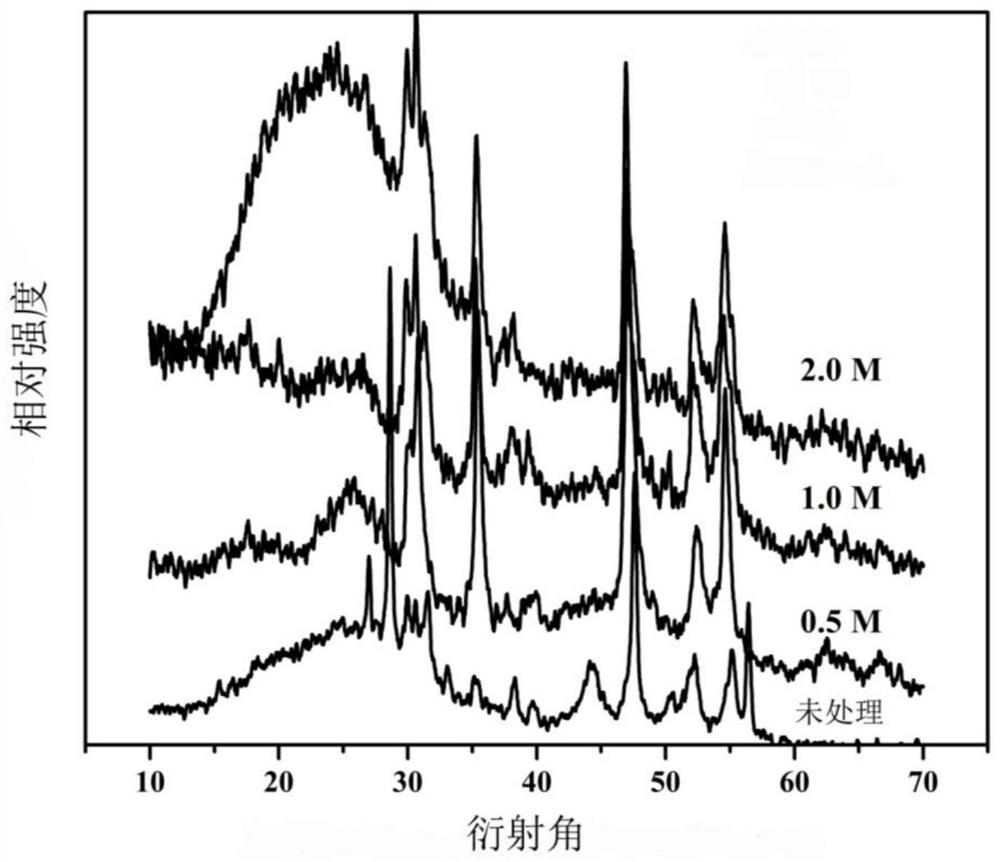

[0053] figure 1 It is the acid stability test chart of the composite material prepared in Example 1. In the figure, untreated refers to the composite material that has not been treated with acid,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com