General scale inhibitor for salt and sodium sulfate co-production technology in salt-making industry

A technology of co-production of salt and nitrate and antiscalant, which is applied in the field of salt industry, can solve problems such as increased equipment corrosion, increased ion membrane voltage, poor calcium and magnesium ion chelation ability, etc., and achieves simplified addition process and high-efficiency chelation Ability, strong dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

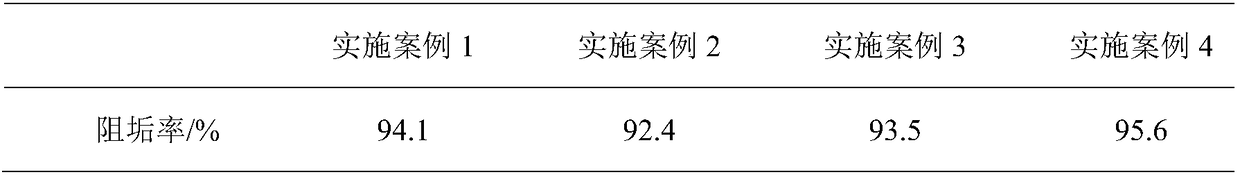

Embodiment 1

[0021] A general-purpose scale inhibitor for co-production of salt and nitrate, prepared according to the following mass fraction percentages:

[0022] Amino trimethylene phosphonic acid 10%; ethylenediamine tetramethylene phosphonic acid 10%; terpolymer T15 30%; hydrolyzed polymaleic anhydride (synthesized by solvent method, molecular weight between 10 million and 20 million) 20%; Antiprex.A (acrylic acid modified) 10%; the balance is deionized water.

[0023] The above-mentioned general-purpose antiscalant for the salt-nitrate co-production process in the salt-making industry is used in the brine pipeline, heating room, preheating room, and evaporation tank of the salt-nitration co-production system, and the addition amount in the refined brine is 10-25mg / L.

Embodiment 2

[0025] A general-purpose scale inhibitor for co-production of salt and nitrate, prepared according to the following mass fraction percentages:

[0026] Amino trimethylene phosphonic acid 5%; ethylenediamine tetramethylene phosphonic acid 15%; terpolymer T15 25%; hydrolyzed polymaleic anhydride (synthesized by solvent method, molecular weight between 10 million and 20 million) 25%; Antiprex.A (acrylic acid modification) 10%; the balance is deionized water.

[0027] The above-mentioned general-purpose antiscalant for the salt-nitrate co-production process in the salt-making industry is used in the brine pipeline, heating room, preheating room, and evaporation tank of the salt-nitration co-production system, and the addition amount in the refined brine is 10-25mg / L.

Embodiment 3

[0029] A general-purpose scale inhibitor for co-production of salt and nitrate, prepared according to the following mass fraction percentages:

[0030] Amino trimethylene phosphonic acid 15%; Ethylenediamine tetramethylene phosphonic acid 5%; Terpolymer T15 20%; Hydrolyzed polymaleic anhydride (synthesized by solvent method, molecular weight between 10 million and 20 million) 20%; Antiprex.A (acrylic acid modification) 20%; the balance is deionized water.

[0031] The above-mentioned general-purpose antiscalant for the salt-nitrate co-production process in the salt-making industry is used in the brine pipeline, heating room, preheating room, and evaporation tank of the salt-nitration co-production system, and the addition amount in the refined brine is 10-25mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com