Barium zirconate titanate-based capacitor ceramic and preparation method thereof

A barium zirconate titanate and capacitor technology, which is applied in the field of barium zirconate titanate-based capacitor ceramics and its preparation, can solve the problems of poor temperature stability, poor dielectric constant temperature stability, and low room temperature dielectric constant. Achieve the effects of improved temperature stability, high dielectric constant, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

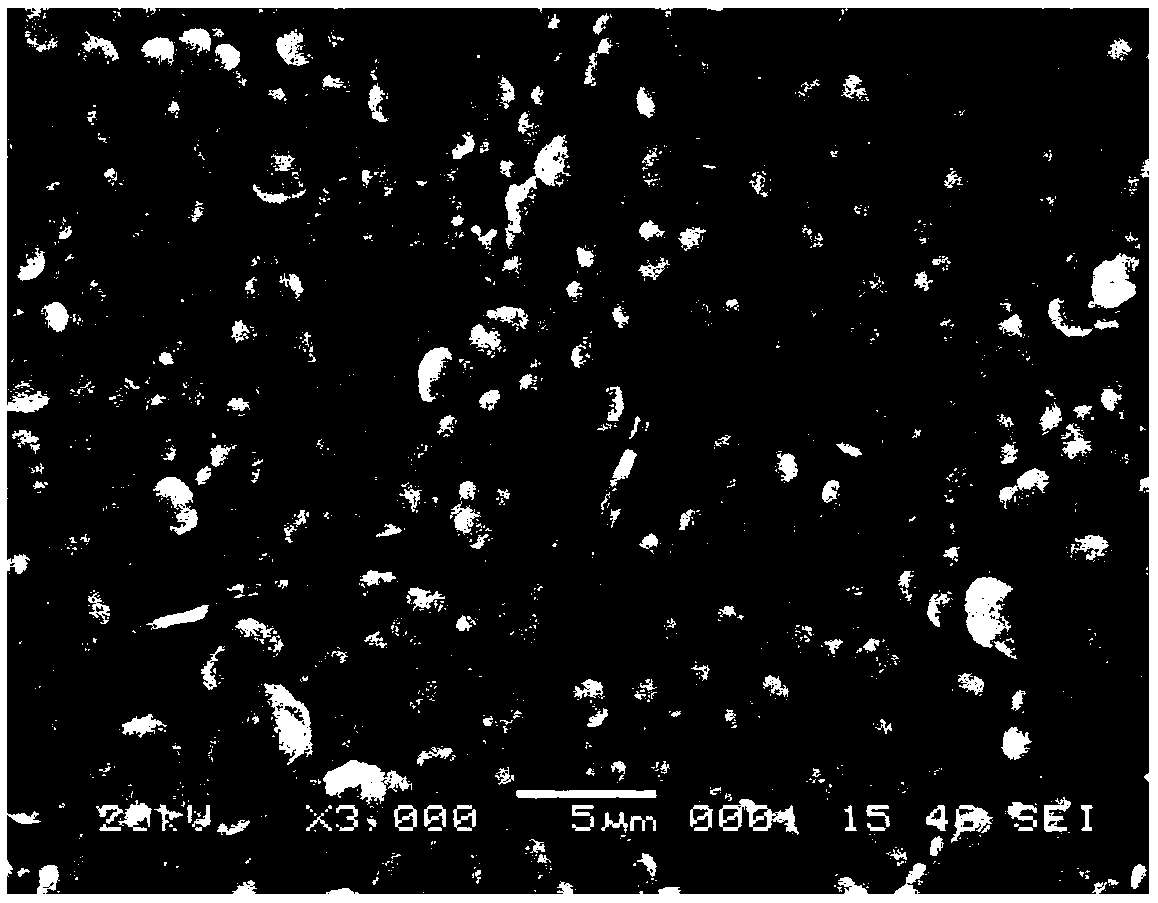

Image

Examples

Embodiment 1

[0024] The chemical formula of porcelain is: 0.97Ba(Zr 0.1 Ti 0.9 )O 3 -0.03Ba(Zn 1 / 3 Nb 2 / 3 )O 3 .

[0025] The preparation method of the ceramic material comprises the following steps:

[0026] (1) Weigh 0.2mol, 0.0194mol, 0.1746mol, 0.002mol, 0.002mol of BaCO respectively 3 , ZrO 2 ,TiO 2 , ZnO and Nb 2 o 5 , mixed to prepare the ingredients, the ingredients and agate balls and deionized water in a mass ratio of 1:2:3 into a nylon ball mill tank, wet ball milling in the tank mill with a speed of 110r / min for 24h to obtain a slurry material, then the slurry was dried at 130°C, controlled temperature increase rate of 300°C / h to 1080°C for 2h, and then synthesized 0.97Ba(Zr 0.1 Ti 0.9 )O3 -0.03Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Main crystal phase powder;

[0027] (2) After wet ball milling the powder prepared above for 24 hours, dry it at 120°C, then add 5wt% polyvinyl alcohol (PVA) aqueous solution to granulate, pass through a 40-mesh sieve, and mold to obtain a Φ10mm tabl...

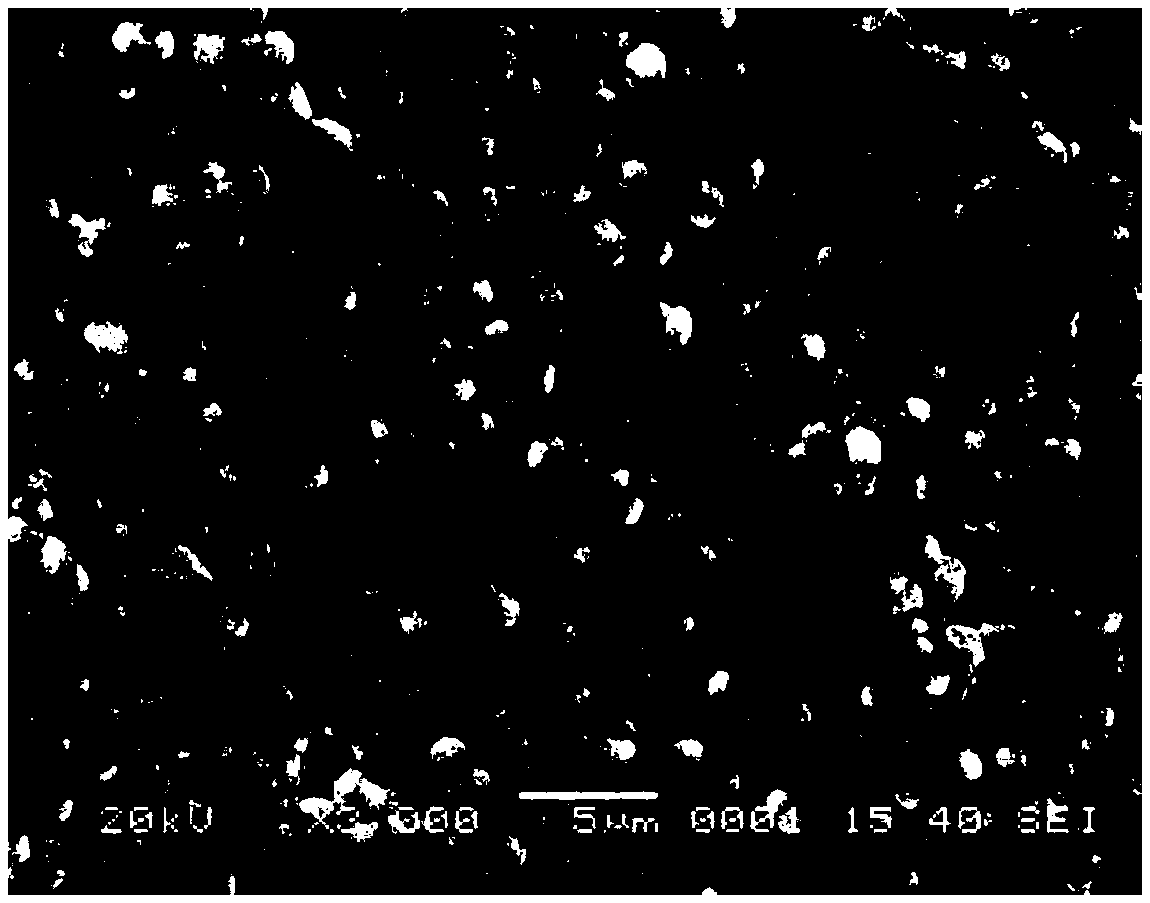

Embodiment 2

[0031] The chemical formula of porcelain is: 0.95Ba(Zr 0.1 Ti 0.9 )O 3 -0.05Ba(Zn 1 / 3 Nb 2 / 3 )O 3 .

[0032] The preparation method of the ceramic material comprises the following steps:

[0033] (1) Weigh 0.2mol, 0.019mol, 0.171mol, 0.00333mol, 0.00333mol of BaCO respectively 3 , ZrO 2 ,TiO 2 , ZnO and Nb 2 o 5 , mixed to prepare ingredients, the ingredients and agate balls and deionized water in a mass ratio of 1:1.5:2.5 into a nylon ball mill tank, wet ball milling in the tank mill at a speed of 110r / min for 24h to obtain a slurry Then the slurry was dried at 130°C, and the temperature was controlled at a rate of 300°C / h to rise to 1100°C for calcination for 2 hours, and the solid phase reaction synthesized 0.95Ba(Zr 0.1 Ti 0.9 )O 3 -0.05Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Main crystal phase powder;

[0034] (2) After wet ball milling the powder prepared above for 24 hours, dry it at 120°C, then add 6wt% polyvinyl alcohol (PVA) aqueous solution to granulate, pass through...

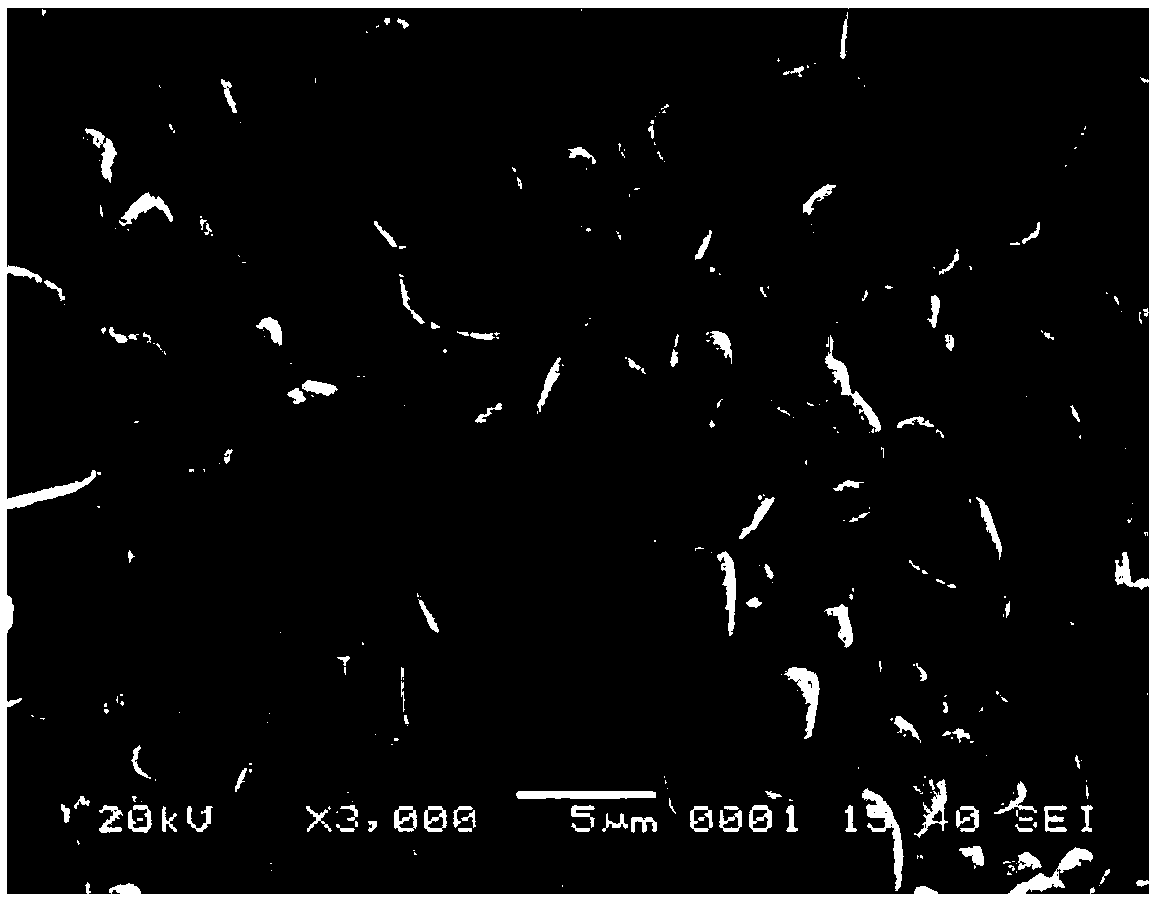

Embodiment 3

[0038] The chemical formula of porcelain is: 0.96Ba(Zr 0.1 Ti 0.9 )O 3 -0.04Ba(Zn 1 / 3 Nb 2 / 3 )O 3 .

[0039] The preparation method of the ceramic material comprises the following steps:

[0040] (1) Weigh 0.2mol, 0.0192mol, 0.1728mol, 0.00266mol, 0.00266mol of BaCO respectively 3 , ZrO 2 ,TiO 2 , ZnO and Nb 2 o 5 , mixed to prepare ingredients, the ingredients and agate balls and deionized water in a mass ratio of 1:1.5:2.5 into a nylon ball mill tank, wet ball milling in a tank mill with a speed of 110r / min for 16h to obtain a slurry Then the slurry was dried at 130°C, and the temperature was controlled at a rate of 300°C / h to rise to 1050°C for calcination for 2 hours, and the solid phase reaction synthesized 0.96Ba(Zr 0.1 Ti 0.9 )O 3 -0.04Ba(Zn 1 / 3 Nb 2 / 3 )O 3 Main crystal phase powder;

[0041] (2) After wet ball milling the powder prepared above for 24 hours, dry it at 120°C, then add 5wt% polyvinyl alcohol (PVA) aqueous solution to granulate, pass throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com