Preparation method of silicone rubber polyurethane thermoplastic elastomer

A thermoplastic elastomer and polyurethane technology, applied in the preparation of silicone rubber polyurethane thermoplastic elastomers, in the field of thermoplastic elastomers, can solve the problems of long mixing time, high cost, poor uniformity, etc. The effect of high efficiency and easy response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

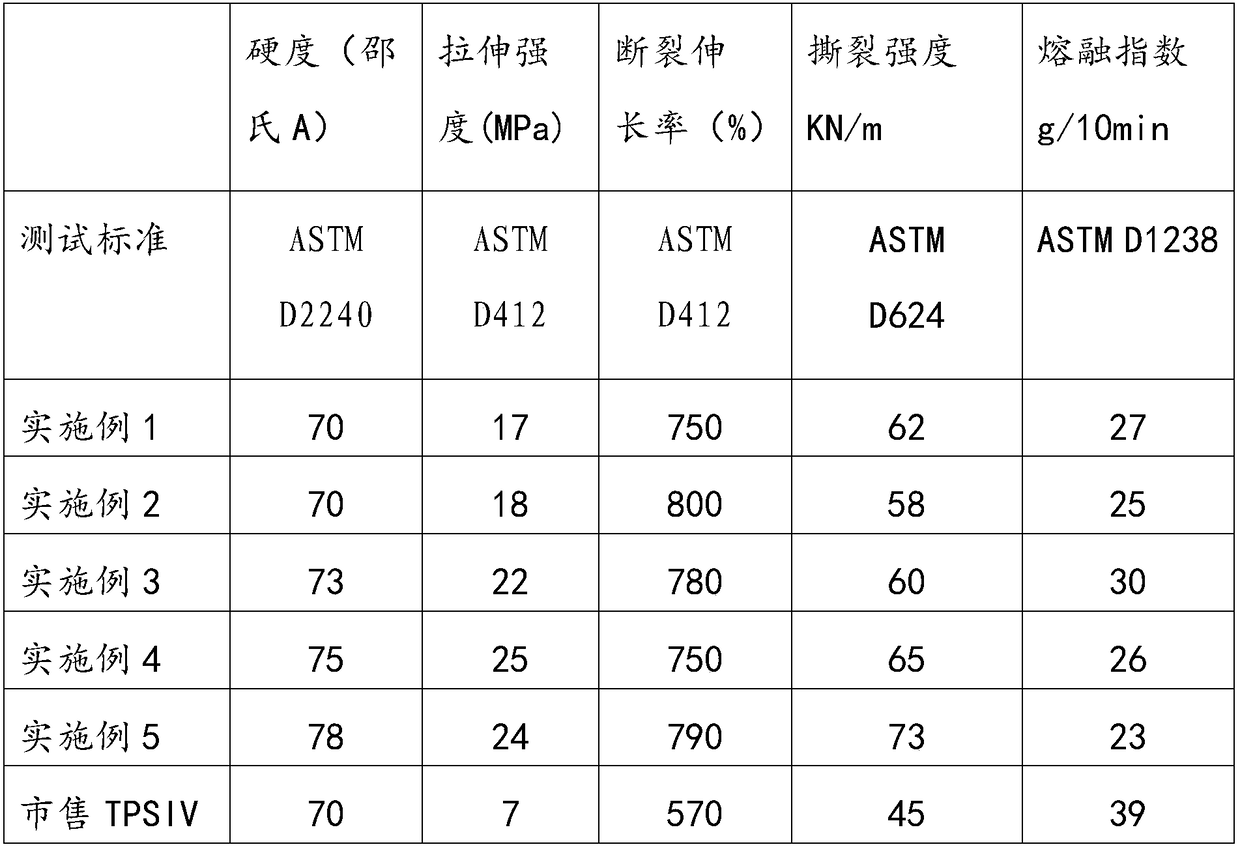

Examples

Embodiment 1

[0030] A kind of preparation of silicone rubber polyurethane thermoplastic elastomer specifically comprises the following steps:

[0031] Step 1: In parts by weight, take the following raw materials: 68.18 parts of polyethylene adipate butanediol ester diol with a molecular weight of 2000 g / mol, 3.66 parts of 1,4-butanediol, diphenylmethane diisocyanate 19.06 parts, liquid methyl silicone rubber 9012A component 5.5 parts, liquid methyl silicone rubber 9012B component 5.5 parts, antioxidant 1010 0.05 parts, light stabilizer 7700.05 parts, lubricant erucamide 0.05 parts and dilaurel 0.05 parts of dibutyltin dilaurate; Among them, liquid methyl silicone rubber 9012 has a viscosity of 6000mP·s at 25°C, and the curing mixing ratio is 1:1. Uniform;

[0032] Step 2: The above-mentioned components are transported to the sprue through a gear pump, mixed and extruded by a twin-screw extruder for continuous reaction. 170°C, 180°C in the sixth, seventh, and eighth zones, 200°C in the ni...

Embodiment 2

[0034] A kind of preparation of silicone rubber polyurethane thermoplastic elastomer specifically comprises the following steps:

[0035] Step 1: In parts by weight, take the following raw materials: 75 parts of polyhexamethylene adipate diol with a molecular weight of 2200 g / mol, 4.25 parts of 1,4-butanediol, 20.75 parts of diphenylmethane diisocyanate, 10 parts of liquid phenyl silicone rubber 9060A component, 5 parts of liquid phenyl silicone rubber 9060B component, 0.03 part of antioxidant 168, 0.08 part of light stabilizer 770, 0.03 part of lubricant ethylene bisoleic acid amide and two 0.03 parts of dibutyltin laurate, in which the viscosity of liquid silicone rubber 9060 at 25°C is 6800mP·s, the curing mixing ratio is 2:1, dibutyltin dilaurate is pre-added to polyhexanediol adipate diol and mixed evenly;

[0036] Step 2: The above-mentioned components are transported to the sprue through a gear pump, mixed and extruded by a twin-screw extruder for continuous reaction. ...

Embodiment 3

[0038] A kind of preparation of silicone rubber polyurethane thermoplastic elastomer specifically comprises the following steps:

[0039] Step 1: In parts by weight, take the following raw materials: 73 parts of polytetrahydrofuran diol with a molecular weight of 2000 g / mol, 4.25 parts of 1,4-butanediol, 22 parts of diphenylmethane diisocyanate, liquid methyl silicone rubber 15 parts of 9017A component, 3 parts of liquid methyl silicone rubber 9017B component, 0.05 part of antioxidant 1010, 0.05 part of light stabilizer 622, 0.05 part of lubricant stearic acid amide and 0.05 part of dibutyltin dilaurate, of which , liquid silicone rubber 9017, viscosity at 25°C is 5000mP·s, curing mixing ratio is 3:1, dibutyltin dilaurate is added to polytetrahydrofuran glycol in advance and mixed evenly;

[0040] Step 2: The above-mentioned components are transported to the sprue through a gear pump, mixed and extruded by a twin-screw extruder for continuous reaction preparation. The temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com