Method for preparing Au@InP nanopore array photo-anode plate material

A nanopore array, photoanode technology, applied in anodizing, electrode, electrode shape/type, etc., can solve the problem of easy recombination of photogenerated electrons and holes, and achieve favorable application prospects for diffusion and migration of photogenerated charges. , the effect of high photocurrent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

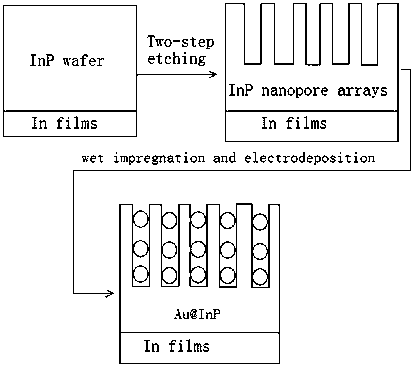

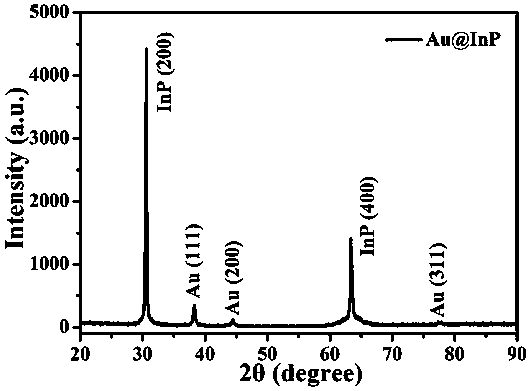

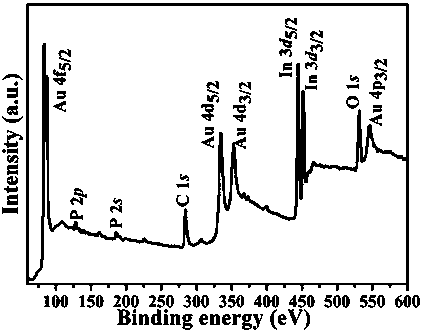

[0037] A method for preparing an Au@InP nanohole array photoanode material. First, an InP wafer is used as a substrate, and a one-dimensional ordered InP nanohole array is prepared by electrochemical anodization combined with wet etching, and then the one-dimensional ordered The InP nanopore array is used as a template, and the Au nanoparticles are uniformly loaded in the InP nanopore array by the impregnation electrochemical deposition method, so as to construct the Au@InP nanopore array composite structure photolysis water photoanode material.

[0038] Such as figure 1 As shown, the preparation of Au@InP nano-heterojunction arrays can be divided into two steps. Firstly, the ordered InP nanohole arrays are prepared by two-step etching method, and then the Au@InP nano-heterojunction arrays are constructed by dipping and electrochemical deposition techniques. Mass knot array.

Embodiment 2

[0040] As a preference of Example 1, the InP wafer is Sn-doped (100) plane n-type single crystal InP, chloroauric acid is the gold source in immersion electrochemical deposition, and neutral sodium chloride solution is the inert electrolyte.

Embodiment 3

[0042] As a preferred embodiment of Example 1, the steps of preparing a one-dimensional InP nanopore array are as follows:

[0043] 1. Perform mechanical mirror polishing on one side of the InP wafer, clean the polished InP wafer to remove the oil on the surface of the InP wafer, then rinse the InP wafer with deionized water several times, and then dry it for later use;

[0044] 2. Use DC magnetron sputtering method to sputter indium film on the unpolished surface of the InP wafer obtained in step 1, and then anneal at a certain temperature. After the annealing, cut the InP wafer into samples of the same size, and then use high-purity The conductive silver paste connects one side of the indium-plated film of the InP sample to the copper wire to prepare the InP electrode;

[0045] 3. Use the InP electrode in step 2 as the anode, and the graphite sheet as the cathode, put the anode and the cathode into the hydrochloric acid solution, and connect the stabilized power supply betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com