Method for fermenting production of butanol

A technology of butanol and fermentation bacteria, applied in the field of microorganisms, can solve the problems of restricting the development of butanol fermentation industry, unable to grow normally, increasing the difficulty of product separation, etc., so as to avoid the phenomenon of non-growth of bacteria and improve the utilization rate of carbon source. , high yield and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the soybean meal hydrolyzate comprises: weighing an appropriate amount of soybean meal, adding 5 times the mass of water, and mixing uniformly. Add concentrated sulfuric acid with a mass concentration of 98% according to 2% of the water volume, mix quickly and evenly, and do not partially carbonize the material. Steam was introduced to raise the temperature of the material to 100°C, and the temperature was kept for 20 hours, during which, it was stirred for 5 minutes every hour. After the hydrolysis is finished, a soybean meal hydrolyzate that is red in sauce and has a fruity aroma is obtained.

[0028] Analyze the products and by-products in the fermentation broth by liquid chromatography to calculate the concentration of the main components: liquid chromatography (Agilent 1200), the chromatographic column is Bio-Rad HPX-87H (300mm×7.8mm), mobile phase 0.005mol / L H2SO4, the flow rate is 0.6 ml / min, the temperature of the column oven is 65°C, ...

Embodiment 1

[0033] Liquid medium (including seed medium and fermentation medium) components: peptone 10 g / L, beef extract 6 g / L, glucose 45 g / L, sodium chloride 0.5 g / L, ammonium sulfate 0.9 g / L, iron sulfate 0.1 g / L, magnesium sulfate 0.3 g / L, calcium chloride 0.1 g / L, potassium dihydrogen phosphate 1 g / L, disodium hydrogen phosphate 2 g / L, p-aminobenzoic acid 0.04 g / L, vitamin B1 0.04 g / L and biotin 0.004g / L, pH 7.0, sterilized at 121°C for 15min. Add 1wt% agar to the liquid medium for solid medium.

[0034] Add the calcium carbonate of 0.5g / L in above-mentioned medium as fermentation medium.

[0035] The method of using Clostridium beijerinckii CGMCC No. 9124 to ferment and produce butanol under facultative conditions includes: (1) inoculating the Clostridium beijerinckii on a solid medium slant, placing it in an anaerobic environment, and culturing at 30°C 24h; (2) Scrape 2 rings of the Clostridium beijerinckii cultivated in step (1) from the slope and insert them into the seed medi...

Embodiment 2

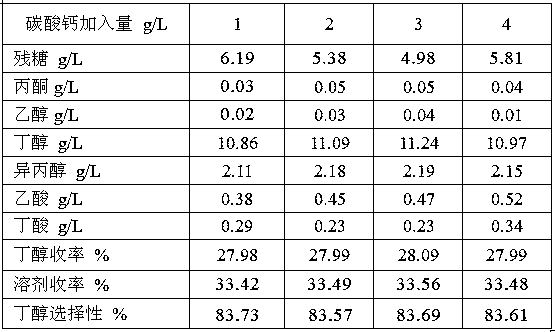

[0037] According to the method of embodiment 1, difference is that calcium carbonate add-on is respectively 1g / L, 2g / L, 3g / L and 4g / L. The results are shown in Table 1.

[0038] Table 1

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com