Method for preparing magnesium aluminum hydrotalcite nanosheets in one step for adsorbing phosphorus removal

A technology of magnesium aluminum hydrotalcite and nanosheets, which is applied in the field of environmental protection, can solve the problems of large specific surface area and small size of hydrotalcite nanosheets, and achieve the effects of good dispersion, short production time and high phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Mix 100mL of urea solution containing 36.0g and 0.01mol·L -1 The sodium nitrate solution was placed in a water bath at 25°C; (2) Weighed 4.096g magnesium nitrate hexahydrate and 3.000g aluminum nitrate nonahydrate respectively and mixed them in 200mL deionized water; (3) Added dropwise to the urea solution Add magnesium-aluminum mixed solution and 1.0mol·L -1 Sodium hydroxide controls the pH to be 10; (4) under nitrogen protection, magnetically stirs for 15 minutes; (5) then at 10000r min -1 Centrifuge at high speed, wash with ethanol and deionized water repeatedly for three times, dry in a freeze dryer for 24 hours, and then grind to obtain hydrotalcite nanosheet powder.

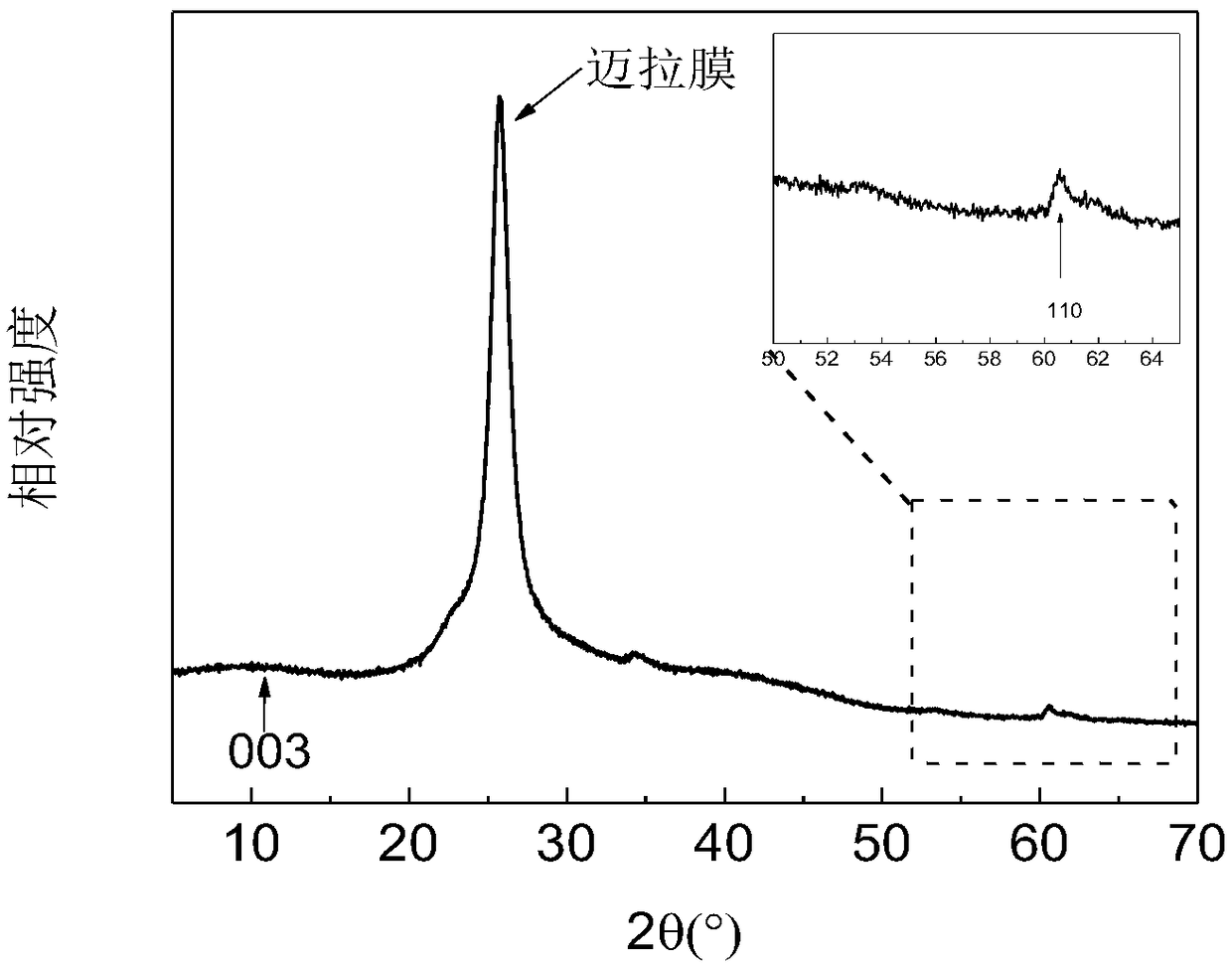

[0025] In this embodiment, the X'Pert PRO MPD X-ray diffractometer (XRD) of PANalytical Company in the Netherlands is used to characterize the crystal structure of the prepared hydrotalcite nanosheets. figure 1 It is the XRD spectrum of hydrotalcite nanosheets. It can be seen from the figure th...

Embodiment 2

[0027] (1) Mix 100mL of urea solution containing 18.0g and 0.01mol·L -1 The sodium nitrate solution was placed in a water bath at 25°C; (2) Weighed 3.072g magnesium nitrate hexahydrate and 2.250g aluminum nitrate nonahydrate respectively, mixed and dissolved in 200mL deionized water; (3) simultaneously added dropwise to the urea solution Add magnesium-aluminum mixed solution and 0.5mol·L -1 Sodium hydroxide controls the pH to 10; (4) under the protection of nitrogen, magnetically stirs for 10 minutes; the rest of the preparation process is repeated in Example 1 (5).

Embodiment 3

[0029] (1) Mix 100mL of urea solution containing 54.0g and 0.01mol·L -1 Place the sodium nitrate solution in a water bath at 25°C; (2) Weigh 5.120g of magnesium nitrate hexahydrate and 3.750g of aluminum nitrate nonahydrate, mix and dissolve them in 200mL of deionized water; (3) drop by drop in the urea solution Add magnesium-aluminum mixed solution and 2.0mol·L -1 Sodium hydroxide was used to control the pH to 10; (4) under nitrogen protection, magnetic stirring was carried out for 30 minutes; the rest of the preparation process was repeated in Example 1 (5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com