Radiation refrigeration optical filter, method for preparing same and application of radiation refrigeration optical filter

A technology of radiative refrigeration and optical filters, applied in optics, optical components, installation, etc., can solve the problems of high preparation cost, difficult processing, unfavorable large-scale and large-area production, etc., and achieve the effect of low preparation cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

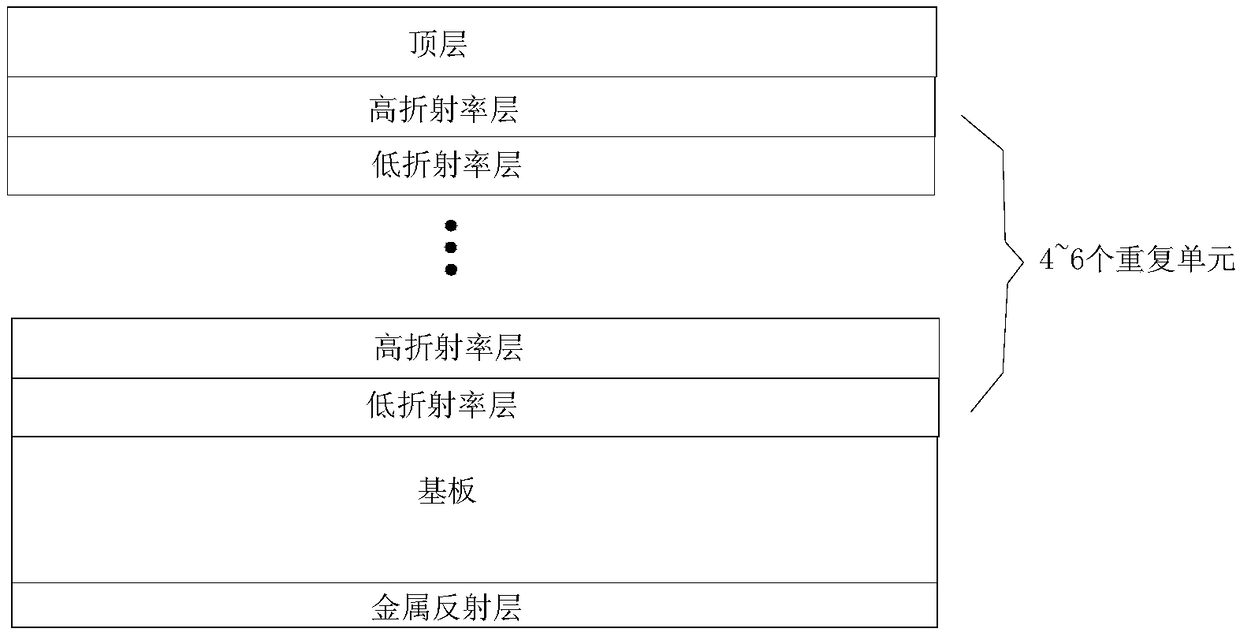

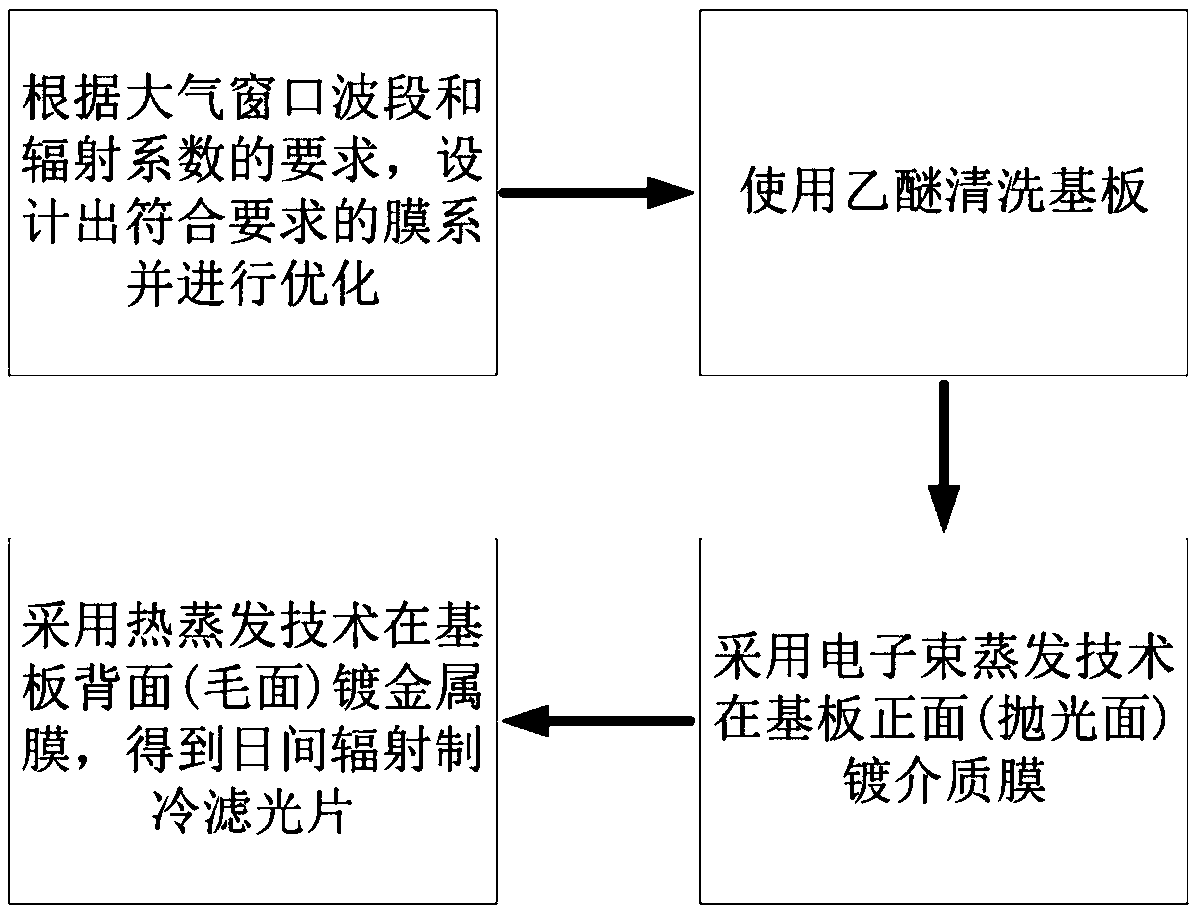

[0077] Such as figure 2 Shown, the preparation method of radiation cooling filter comprises the following steps:

[0078] 1) Based on the spectral characteristics of the three colors of red, green and blue, and considering the emissivity requirements of the atmospheric transparent window, the film system that meets the requirements is designed by optimizing the film system design, including the choice of film material and thickness optimization;

[0079] 2) Put the substrate into the ether solution and ultrasonically clean it for 8 minutes to ensure the cleanliness of the substrate surface;

[0080] 3) First, the middle layer and the top layer of the smooth surface of the substrate are sequentially deposited by electron beam evaporation technology, and then a metal reflective layer is plated on the rough surface of the substrate to obtain a radiation cooling filter.

Embodiment 1

[0082] The corresponding substrate material is white glass, the substrate is polished on one side, and the rough surface is coated with a metal reflective layer. The material of the metal reflective layer is silver (>100nm); an intermediate layer is deposited on the smooth surface of the substrate. The layers are stacked alternately, and the top layer of zinc sulfide (98nm) is deposited on the middle layer.

[0083] From the substrate to the top layer, the deposition parameters of the middle layer are as follows:

[0084]

[0085]

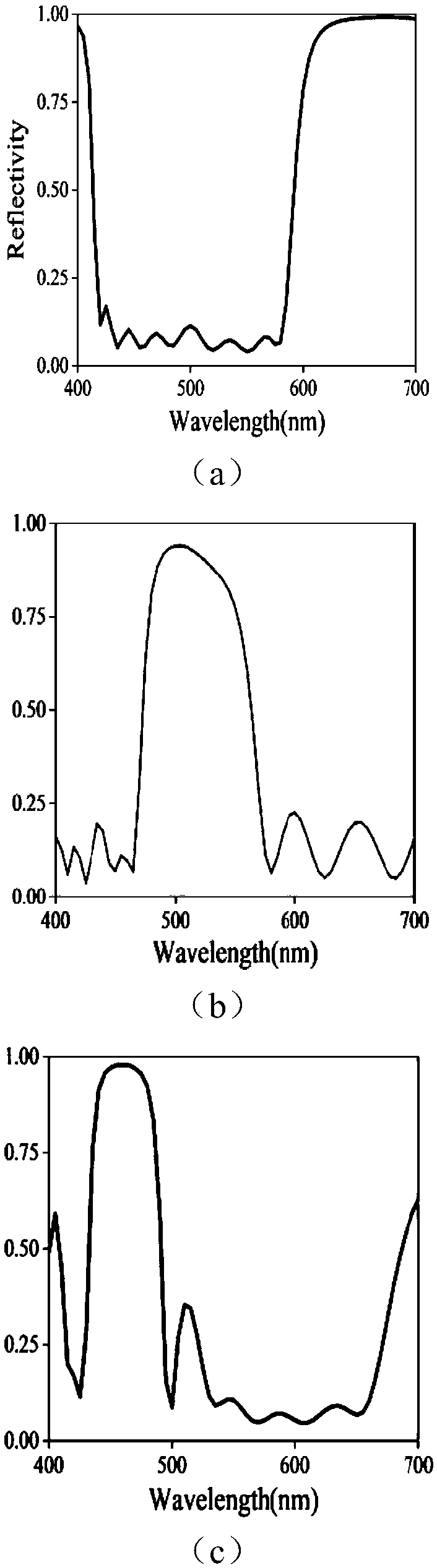

[0086] The visible light spectrum of the obtained radiation cooling filter is as follows: image 3 As shown in (a), the average reflectance in the 630-680nm band is 98.8%, and the average reflectance in the 420-580nm band is 7.6%, which is a red filter.

[0087] At normal incidence, the average emissivity of the filter's atmospheric transparent window is given by Figure 4 shown.

[0088] The filter is insensitive to the angle of radiation...

Embodiment 2

[0090] The corresponding substrate material is white glass, the substrate is polished on one side, and the rough surface is coated with a metal reflective layer. The material of the metal reflective layer is silver (>100nm); an intermediate layer is deposited on the smooth surface of the substrate. The layers are stacked alternately, and the top layer of zinc sulfide (170nm) is deposited on the middle layer.

[0091] From the substrate to the top layer, the deposition parameters of the middle layer are as follows:

[0092] film layer

Material

Thickness / nm

1

TiO 2

104

2

SiO 2

168

3

TiO 2

112

4

SiO 2

148

5

TiO 2

130

6

SiO 2

124

7

TiO 2

143

8

SiO 2

104

9

TiO 2

163

10

SiO 2

62

[0093] The visible light spectrum of the obtained radiation cooling filter is as follows: image 3 As shown in (b), the average reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com