Preparation method of graphene oxide-clad spiral carbon pipe three-dimensional composite materials and photochemical reduction nitrogen doping

A technology of ene-coated helix and composite materials, which is applied in the field of performance improvement of graphene materials to achieve high electrical conductivity, improved performance, and easy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

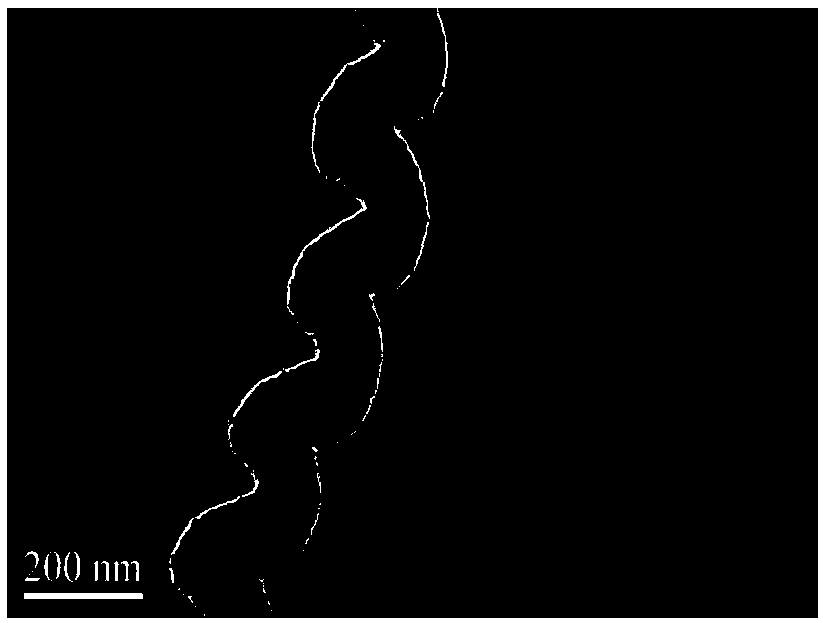

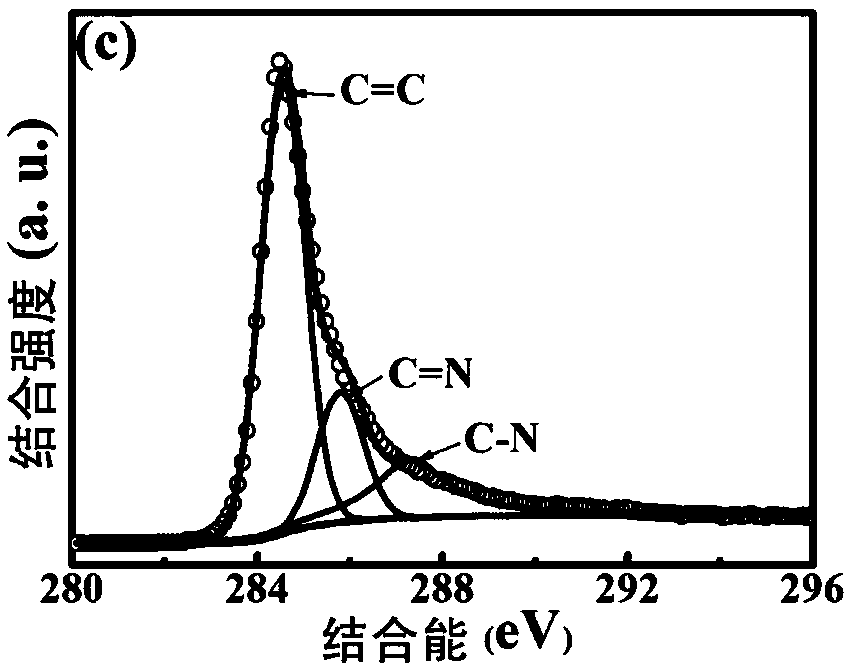

Image

Examples

Embodiment 1

[0036] (1) Mix 8g of flake graphite with 8g of sodium nitrate, add 384mL of concentrated sulfuric acid with a mass percentage concentration of 96.5% and soak for one day. The soaking process makes the sulfuric acid fully contact with the graphite, and the graphite will be more easily oxidized.

[0037] (2) Slowly add 48g potassium permanganate to the mixture obtained in step (1), note that the whole system is put into a low temperature constant temperature reaction bath, keep the temperature below zero degrees Celsius, and magnetically stir for 1.5 hours; the color of the reactant is changed from black After turning dark green, adjust the reaction temperature to 35°C and react for 2 hours. During this process, pay attention to temperature control so that the graphite is fully oxidized; then add 320mL water to the reactant dropwise with a dropping funnel, and stir for 15 minutes; continue Add 800mL of water and 40mL of 29.5% hydrogen peroxide solution by mass, and stir for 10 mi...

Embodiment 2

[0062] (1) Mix 8g of flake graphite with 8g of sodium nitrate, add 384mL of concentrated sulfuric acid with a mass percentage concentration of 96.5% and soak for one day. The soaking process makes the sulfuric acid fully contact with the graphite, and the graphite will be more easily oxidized.

[0063] (2) Slowly add 48g potassium permanganate to the mixture obtained in step (1), note that the whole system is put into a low temperature constant temperature reaction bath, keep the temperature below zero degrees Celsius, and magnetically stir for 1.5 hours; the color of the reactant is changed from black After turning dark green, adjust the reaction temperature to 35°C and react for 2 hours. During this process, pay attention to temperature control so that the graphite is fully oxidized; then add 320mL water to the reactant dropwise with a dropping funnel, and stir for 15 minutes; continue Add 800mL of water and 40mL of 29.5% hydrogen peroxide solution by mass, and stir for 10 mi...

Embodiment 3

[0081] (1) Mix 8g of flake graphite with 8g of sodium nitrate, add 384mL of concentrated sulfuric acid with a mass percentage concentration of 96.5% and soak for one day. The soaking process makes the sulfuric acid fully contact with the graphite, and the graphite will be more easily oxidized.

[0082] (2) Slowly add 48g potassium permanganate to the mixture obtained in step (1), note that the whole system is put into a low temperature constant temperature reaction bath, keep the temperature below zero degrees Celsius, and magnetically stir for 1.5 hours; the color of the reactant is changed from black After turning dark green, adjust the reaction temperature to 35°C and react for 2 hours. During this process, pay attention to temperature control so that the graphite is fully oxidized; then add 320mL water to the reactant dropwise with a dropping funnel, and stir for 15 minutes; continue Add 800mL of water and 40mL of 29.5% hydrogen peroxide solution by mass, and stir for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com