Ultrahigh-temperature-resistant and complex-salt-resistant amphoteric ion hydrophobic association polymer filter loss reducer and preparation method thereof

A fluid loss reducing agent, zwitterion technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of low product conversion rate, poor fluid loss reducing agent effect, low initiation efficiency, etc. Excellent salt performance, improving mud cake quality, suppressing overdispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

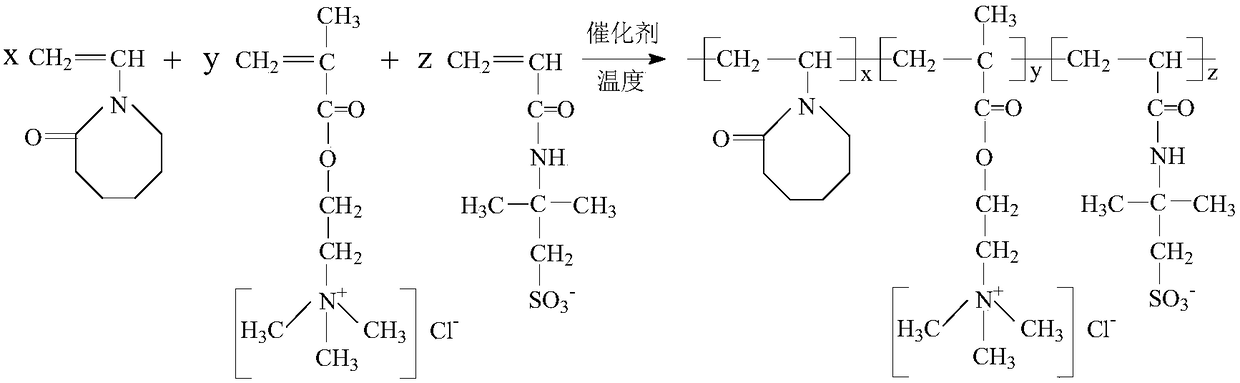

Method used

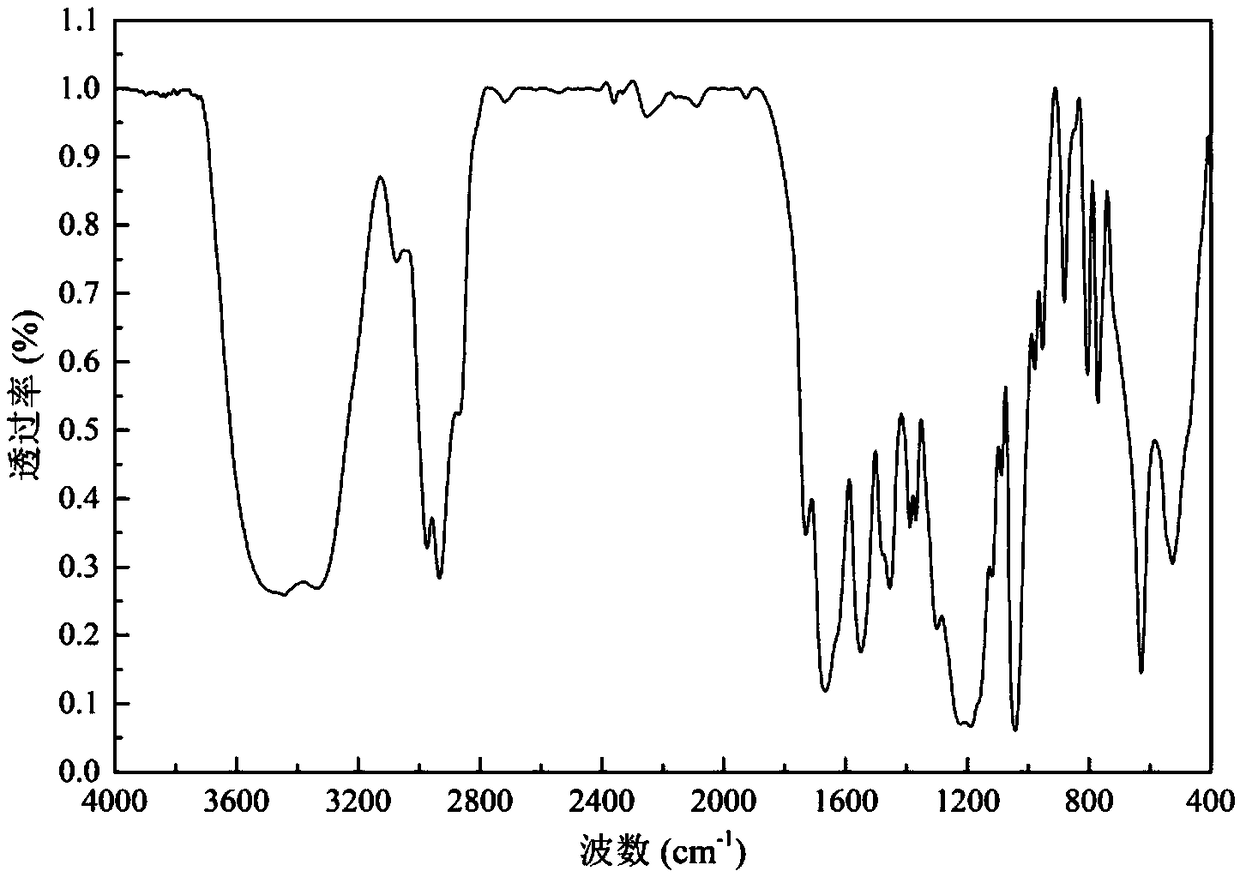

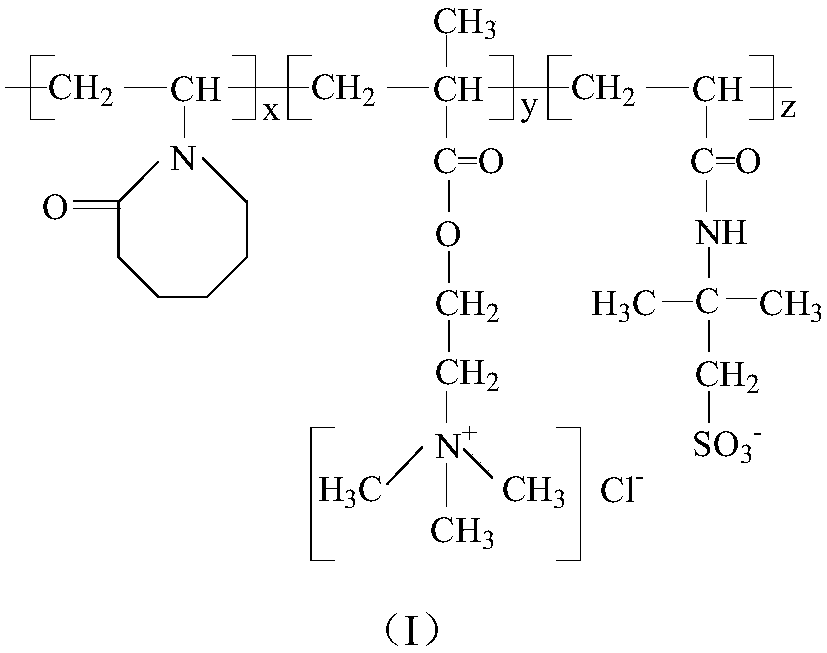

Image

Examples

Embodiment 1

[0048] Weigh 24.84 grams of 2-acrylamide-2-methyl-propanesulfonic acid into a 1-liter reactor equipped with a stirrer, reflux condenser, nitrogen protection device, temperature sensor and heating device and dissolve it in 120 Adjust the pH to 7 with 14 mol / L NaOH solution in ml of tap water and place it in the reaction kettle; then weigh 18.63 g of methacryloxyethyl trimethylammonium chloride and dissolve it in 50 ml of tap water. After the dissolution is complete, pour it into the reactor, then place the reactor in a 40℃ water bath and stir at low speed; melt the N-vinylcaprolactam in an environment of 40-45℃, and then weigh 3.39 grams of N-vinylcaprolactam Then pour into the reactor and stir quickly for 5 minutes; add tap water mixed with 0.1171 g of azobisisobuimidazoline hydrochloride, then add tap water to adjust the total mass concentration of the reaction monomer to 12%, and stir at high speed under nitrogen protection After 30 minutes, the temperature was raised to 55°C...

Embodiment 2

[0051] Weigh 25.70 grams of 2-acrylamide-2-methyl-propanesulfonic acid into a 1-liter reactor equipped with a stirrer, reflux condenser, nitrogen protection device, temperature sensor and heating device and dissolve it in 150 Adjust the pH to 7-8 with 14 mol / L NaOH solution in ml of tap water and place it in the reactor; then weigh 11.66 g of methacryloxyethyl trimethylammonium chloride and dissolve it in 50 ml of tap water After the dissolution is complete, pour into the reactor, then place the reactor in a 40℃ water bath and stir evenly at low speed; add tap water mixed with 0.1031 g of azoisobutylcyanoformamide, and then add tap water to a total of 276 Then melt the N-vinylcaprolactam in an environment of 40-45℃, then weigh 3.89g of N-vinylcaprolactam and pour it into the reactor, stir quickly for 5 minutes; then measure out 69ml of No. 5 white The oil was added to the reaction kettle, stirred at high speed for 30 minutes under the protection of nitrogen, and then heated to ...

Embodiment 3

[0054] To a stainless steel corrosion-resistant reactor with a capacity of 3-3.5 tons equipped with a stirrer, a reflux condenser, a nitrogen protection device, a thermometer and a heating device, first add 500 kg of tap water, turn on the stirrer, and remove it at a rate of 25 kg / min. 140 kg of 2-acrylamide-2-methyl-propanesulfonic acid was added to the reactor, stirred for 10 minutes, sodium hydroxide solid was added at a rate of 5 kg / min, and the pH was adjusted to 7-8. In the reactor Add tap water to 1500 kg, stir for 10 minutes, add 105 kg of methacryloxyethyl trimethyl ammonium chloride, continue stirring for 10 minutes, then melt N-vinylcaprolactam in an environment of 40-45°C, and then weigh Take 19.2 kg of N-vinylcaprolactam and pour it into the reaction kettle, continue to stir for 10 minutes; add tap water mixed with 0.6605 kg of azobisbuimidazoline hydrochloride, and then continue to add tap water until the total weight of tap water is 2200 kg , Blow nitrogen, stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com