A method of improving the adhesion of flexible transparent conductive film

A technology of transparent conductive film and transparent conductive layer, which is applied to the conductive layer, circuit, electrical components and other directions on the insulating carrier, can solve the problems of easy scratching and falling off of the transparent conductive film, limiting the application of PEDOT conductive film, etc. Low cost, high light transmittance, improved peeling and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the examples, PEDOT:PSS was purchased from Heraeus, Germany, product model PH1000. Other drugs and solvents were purchased from Sinopharm Chemical Reagent Co., Ltd.

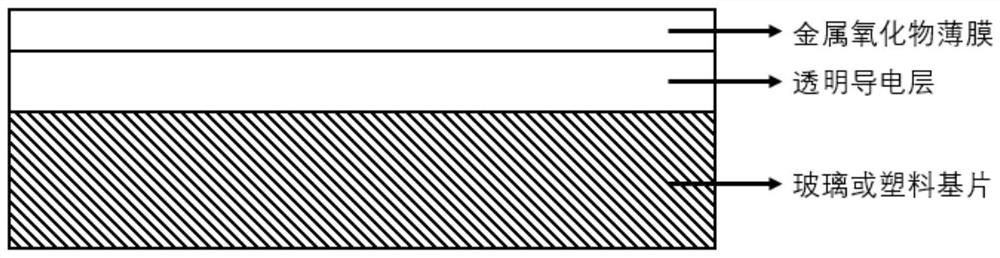

[0052] Such as figure 1 and figure 2 Shown, a kind of method for improving the adhesiveness of flexible transparent conductive film is characterized in that, comprises the following steps:

[0053] 1) Preparation of organic polymer conductive ink

[0054] Add 5mL of PEDOT:PSS dispersion liquid and 5% dimethyl sulfoxide into the container successively, after stirring, the conductive ink doped with organic polymer is obtained;

[0055] In the stirring process: the stirring rate is 500rpm, and the stirring time is 20min.

[0056] 2) Preparation of metal oxide quantum dots

[0057] Mix 2ml of zinc acetate solution, 1ml of sodium hydroxide solution and 10ml of isopropanol, and disperse evenly to obtain a metal oxide quantum dot solution;

[0058] The concentration of the zinc acetate solution is 0.01-...

Embodiment 2

[0078] A method for improving the adhesion of a flexible transparent conductive film, characterized in that it comprises the following steps:

[0079] 1) Preparation of organic polymer conductive ink

[0080] Add 5mL of PEDOT:PSS dispersion liquid and 5% dimethyl sulfoxide into the container successively, after stirring, the conductive ink doped with organic polymer is obtained;

[0081] In the stirring process: the stirring rate is 500rpm, and the stirring time is 20min.

[0082] 2) Coating a layer of conductive ink on the base material

[0083] Coating the organic polymer conductive ink obtained in step 1) on the base material after pretreatment;

[0084] The pretreatment process of described substrate material is:

[0085] Cut the base material into a square base of 20mm×20mm, clean it with detergent, deionized water, acetone, and isopropanol in sequence for 20 minutes, and then use high-purity nitrogen to remove residues from the base material;

[0086] Put the dried s...

Embodiment 3

[0094] A method for improving the adhesion of a flexible transparent conductive film, characterized in that it comprises the following steps:

[0095] 1) Preparation of organic polymer conductive ink

[0096] Add 5mL of PEDOT:PSS dispersion liquid and 5% dimethyl sulfoxide into the container successively, after stirring, the conductive ink doped with organic polymer is obtained;

[0097] In the stirring process: the stirring rate is 500rpm, and the stirring time is 20min.

[0098] 2) Preparation of metal oxide quantum dots

[0099] Mix 2ml of zinc acetate solution, 1ml of sodium hydroxide solution and 10ml of isopropanol, and disperse evenly to obtain a metal oxide quantum dot solution;

[0100] The concentration of the zinc acetate solution is 0.01-1M;

[0101] The concentration of the sodium hydroxide is 0.05~1M;

[0102] 3) Coating a layer of conductive ink on the base material

[0103] The 50 μm thick optical PET substrate was cut into A4 paper size, cleaned with dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com