A kind of processing method of concentrated ginger juice

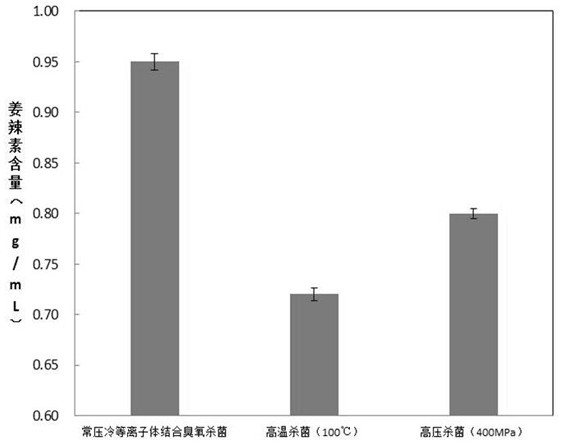

A processing method and technology for concentrated juice, which are applied in the preservation of food ingredients as antimicrobials, food freezing, fresh-keeping of fruits and vegetables, etc., can solve problems such as enzymatic browning of contact areas, achieve a low browning index, reduce enzymatic browning, etc. variable, low activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Raw material processing

[0032] Choose fresh ginger that is tender and thick without moth-eaten rot, wash off the soil and sundries with clean water, and peel and slice the cleaned ginger with a thickness of about 1cm;

[0033] (2) Liquid nitrogen spray freezing

[0034] The ginger treated in step (1) is sprayed with liquid nitrogen under the conditions of liquid nitrogen content of 0.001kg / s and freezing temperature of 0°C;

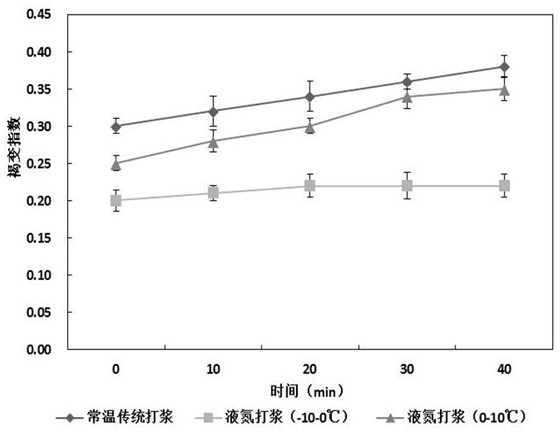

[0035] (3) Liquid nitrogen exhaust oxygen beating

[0036] Add water to the ginger treated in step (2) at a liquid-to-solid ratio of 1:3g / ml, add citric acid accounting for 1.6‰ of the water mass, and then use a crusher to crush the fresh ginger slices into a coarse slurry. During the beating process, liquid nitrogen was input for deoxygenation. The beating speed is 20000r / min, the time is 6min, the liquid nitrogen content is 0.001kg / s, and the temperature is 0°C;

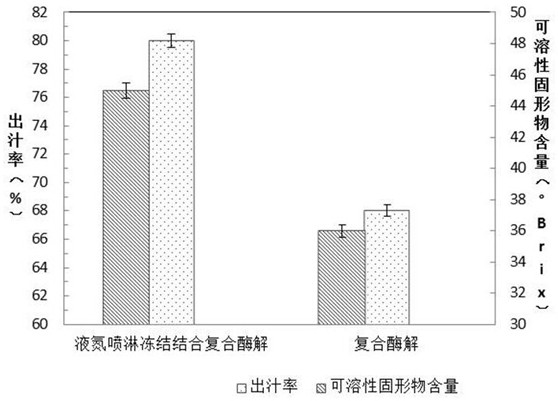

[0037] (4) Complex enzymatic hydrolysis

[0038] Put the slurry treated ...

Embodiment 2

[0046] (1) Raw material processing

[0047] Choose fresh ginger that is tender and thick without moth-eaten rot, wash off the soil and sundries with clean water, and peel and slice the cleaned ginger with a thickness of about 1cm;

[0048] (2) Liquid nitrogen spray freezing

[0049] The ginger treated in step (1) is sprayed with liquid nitrogen at a liquid nitrogen content of 0.002kg / s and a freezing temperature of -5°C;

[0050] (3) Liquid nitrogen exhaust oxygen beating

[0051] Add water to the ginger treated in step (2) at a liquid-to-solid ratio of 1:4 g / ml, add citric acid accounting for 1.6‰ of the water mass, and then use a crusher to crush the fresh ginger slices into a coarse slurry. During the beating process, liquid nitrogen was input for deoxygenation. The beating speed is 22500r / min, the time is 5min, the liquid nitrogen content is 0.002kg / s, and the temperature is -5°C;

[0052] (4) Complex enzymatic hydrolysis

[0053] Put the slurry treated in step (3) in a...

example example 3

[0061] (1) Raw material processing

[0062] Choose fresh ginger that is tender and thick without moth-eaten rot, wash off the soil and sundries with clean water, and peel and slice the cleaned ginger with a thickness of about 1cm;

[0063] (2) Liquid nitrogen spray freezing

[0064] The ginger treated in step (1) is sprayed with liquid nitrogen at a liquid nitrogen content of 0.003kg / s and a freezing temperature of -10°C;

[0065] (3) Liquid nitrogen exhaust oxygen beating

[0066] Add water to the ginger treated in step (2) at a liquid-to-solid ratio of 1:5 g / ml, add citric acid accounting for 1.6‰ of the water mass, and then use a crusher to crush the fresh ginger slices into a coarse slurry. During the beating process, liquid nitrogen was input for deoxygenation. The beating speed is 25000r / min, the time is 4min, the liquid nitrogen content is 0.003kg / s, and the temperature is -10°C;

[0067] (4) Complex enzymatic hydrolysis

[0068] Put the slurry treated in step (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com