Ceramic alloy coating and coating layer

A ceramic alloy and coating technology, applied in the field of ceramic alloy coatings and coatings, can solve the problems of coating failure, limited toughening effect, shutdown, etc., and achieve the effect of ensuring hardness, construction difficulty and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

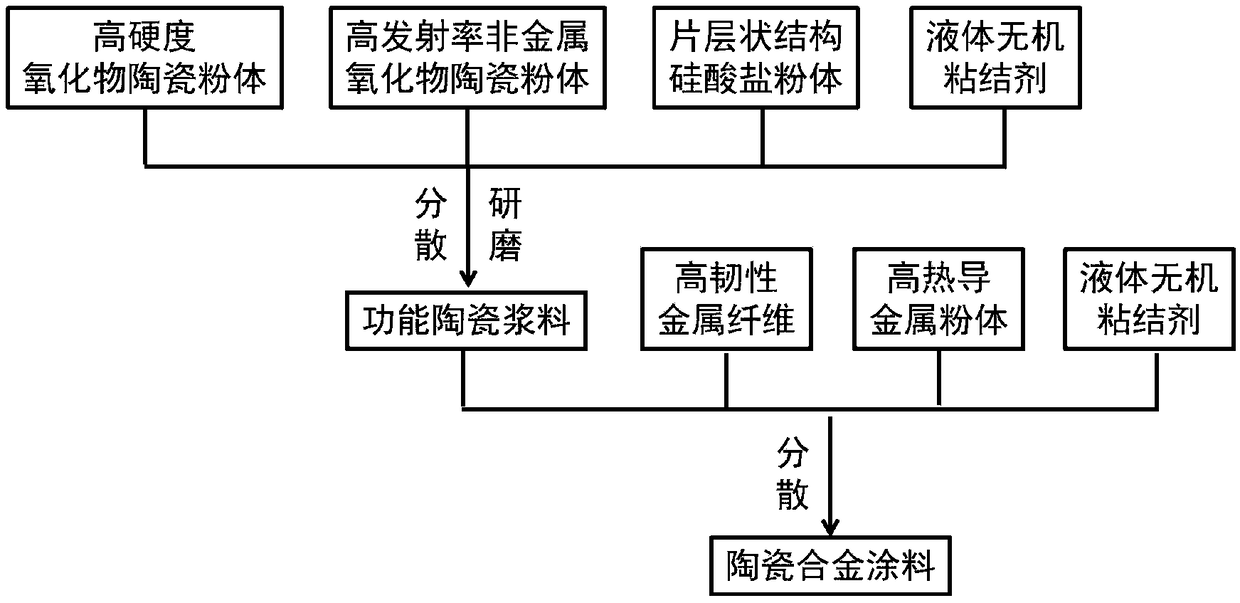

Method used

Image

Examples

Embodiment 1

[0041] Weigh the high hardness Al 2 O 3 25 kg of ceramic powder, 30 kg of SiC ceramic powder with high emissivity, 15 kg of kaolin, and 50 kg of sodium silicate aqueous solution, pour into a stirring vessel, stir evenly to obtain a liquid mixture; inject the above liquid mixture into the vertical In the sand mill, the ball-to-battery ratio is 1:1, the sand is homogenized for 2 hours, and the high-temperature functional ceramic slurry is obtained after filtration.

[0042] Weigh 40 kilograms of high-toughness metallic Cr fiber, 20 kilograms of high thermal conductivity aluminum powder, and 50 kilograms of sodium silicate aqueous solution into a stirring vessel for stirring treatment, add the high-temperature functional ceramic slurry prepared above and stir at high speed for 30 minutes. After filtering, the high-temperature ceramic alloy coating is obtained after packaging.

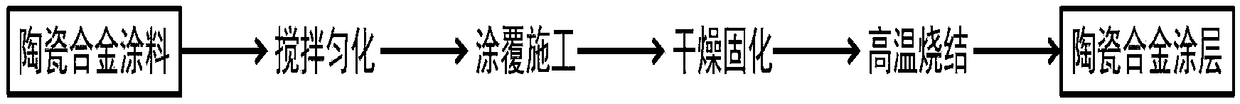

[0043] The obtained high-temperature ceramic alloy coating is stirred and filtered, sprayed onto the surface...

Embodiment 2

[0046] Weigh high hardness SiO 2 Ceramic powder 30 kg, high emissivity Si 3 N 4 30 kg of ceramic powder, 40 kg of montmorillonite, and 80 kg of potassium silicate aqueous solution are poured into a stirring vessel and stirred evenly to obtain a liquid mixture; the above liquid mixture is injected into a vertical sand mill with a ball-to-material ratio of 1:1, sanding and homogenizing treatment for 2 hours, and filtering treatment to obtain high-temperature functional ceramic slurry.

[0047] Weigh 20 kilograms of high-toughness metallic Ni fiber, 10 kilograms of high thermal conductivity copper powder, and 40 kilograms of potassium silicate aqueous solution into a stirring vessel for stirring treatment. Add the high-temperature functional ceramic slurry prepared above and stir at high speed for 30 minutes. After filtering, the high-temperature ceramic alloy coating is obtained after packaging.

[0048] The obtained high-temperature ceramic alloy coating is stirred and filtered, spr...

Embodiment 3

[0051] Weigh high hardness ZrO 2 40 kg of ceramic powder, 40 kg of BN ceramic powder with high emissivity, 10 kg of rectorite, 60 kg of aluminum dihydrogen phosphate aqueous solution, pour into a stirring vessel, stir evenly to obtain a liquid mixture; combine the above liquid mixture Inject into a vertical sand mill with a ball-to-battery ratio of 1:1, sand and homogenize for 2 hours, and filter to obtain high-temperature functional ceramic slurry.

[0052] Weigh 15 kilograms of high-toughness metal Ti fiber, 25 kilograms of high thermal conductivity aluminum powder, and 30 kilograms of aluminum dihydrogen phosphate aqueous solution into a stirring vessel for stirring. Add the high-temperature functional ceramic slurry prepared above and stir at high speed for 30 minutes , After filtering and packaging, high-temperature ceramic alloy coatings can be obtained.

[0053] The obtained high-temperature ceramic alloy coating is stirred and filtered, sprayed onto the surface of the metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com