Photovoltaic polyolefin encapsulating adhesive film

A technology for encapsulating adhesive films and polyolefins. It is used in applications, adhesives, household appliances, etc. It can solve problems such as differences in glass batch stability, decreased adhesion between polyolefin films and glass, and delamination of polyolefin films. , to reduce the phenomenon of salting out, solve the delamination of polyolefin packaging film, and improve the hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

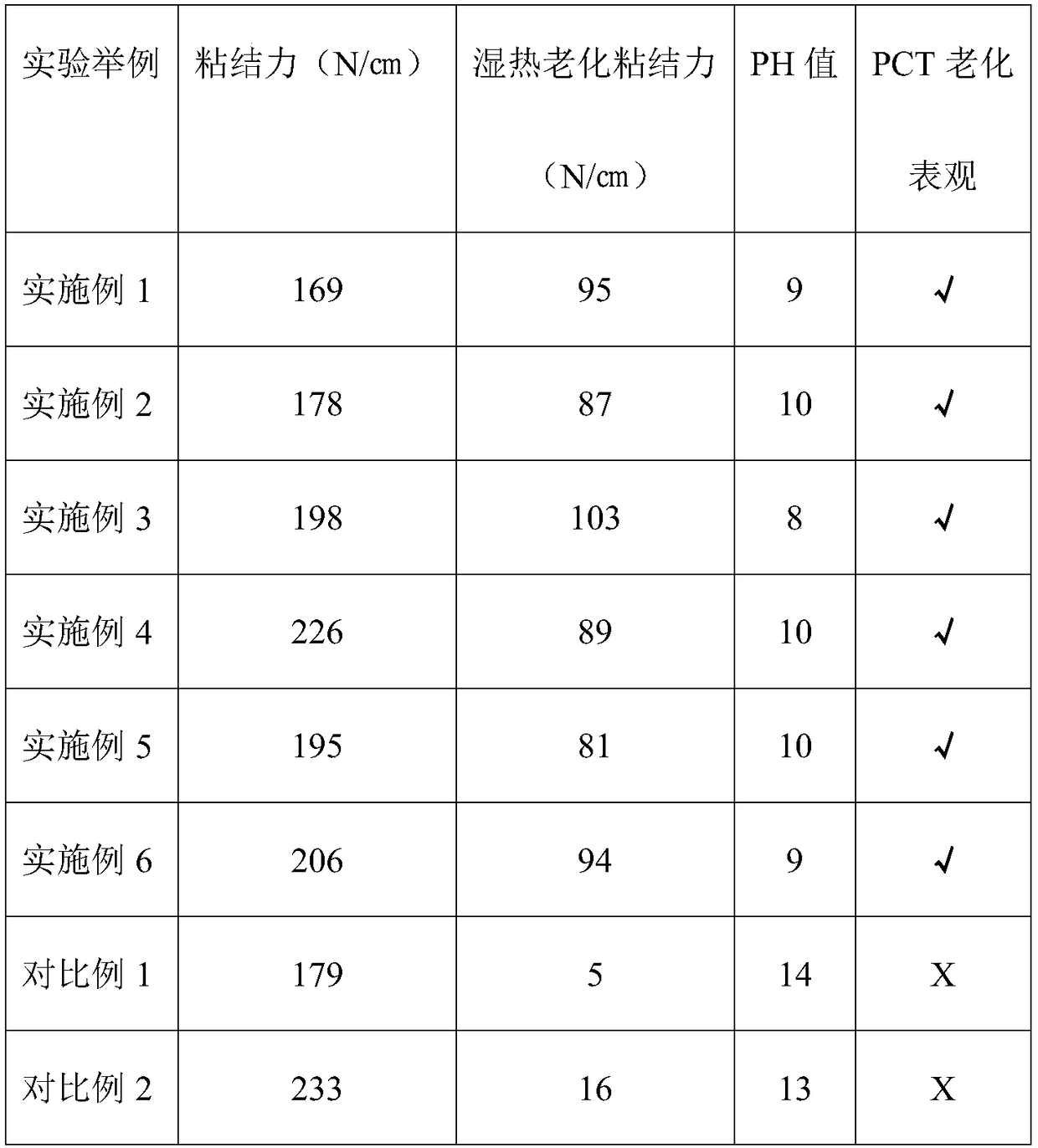

Examples

Embodiment 1

[0044] Ethylene-1-octene random copolymer (Dow Chemical ENGAGE 8137) 100g, in which 0.1g tert-butylperoxycarbonate-2-ethylhexyl ester was added as a crosslinking agent, and 0.1g trimethylolpropane trimethyl Base acrylate as a crosslinking agent, 2g of anti-aging agent (containing 0.8g of 2,2'-dihydroxy-4-methoxybenzophenone as a UV absorber, 0.6g of Lowilite-62 and Lowilite- 94 weight ratio 1:1 mixture as light stabilizer, 0.2g of tetra[methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester and 0.1g of tri (2,4-Di-tert-butylphenyl) phosphite as an antioxidant, 0.2g of nano-magnesium hydroxide as an acid absorbent, 0.1gMgAl(CO 3 )(OH)·nH 2 O as a metal ion trapping agent), 0.05g γ-(methacryloxy)propyltrimethoxysilane as a silane coupling agent, 4g hydrogenated C5 petroleum resin (Puyang Kairuide Petroleum Resin Co., Ltd. BT100, softening point 90-100°C) as a stabilizer. The uniformly mixed materials are added to the melt-extrusion casting machine for extru...

Embodiment 2

[0046] Propylene-ethylene random copolymer (Dow Chemical VERSIFY 3401) 100g, in which 2.5g of tert-butylperoxycarbonate-2-ethylhexyl ester was added as a crosslinking agent, and 0.5g of pentaerythritol tetramethacrylate was used as a crosslinking aid Coupling agent, 0.05g anti-aging agent (containing 0.05 parts of Lowilite-62 and Lowilite-94 weight ratio 1:1 mixture as light stabilizer), 10g silane grafted POE, 0.05 parts of γ-(methacryloyloxy) ) Propyltrimethoxysilane is used as a silane coupling agent, and 0.7g of n-octyltriethoxysilane is used as a stabilizer. The uniformly mixed materials are added to the melt-extrusion casting machine for extrusion, and the temperature is controlled at 100°C. The extrudate is cast, cooled, drawn, and crimped to obtain a polyolefin encapsulating film with a thickness of 0.45 mm.

Embodiment 3

[0048] Propylene-ethylene random copolymer (ExxonMobil Vistamaxx 6202FL) 100g, in which 2g tetracosyl peroxydicarbonate is added as a crosslinking agent, 3g 1,3,5-triallyl-s-triazine- 2,4,6-triketone is used as a crosslinking agent, 1g of anti-aging agent (0.1g of Lowilite-62 and Lowilite-94 weight ratio 1:1 mixture as light stabilizer, 0.2g of tetra[methyl- A mixture of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.1 g of tris(2,4-di-tert-butylphenyl) phosphite as an antioxidant , 0.3g of nano-magnesium hydroxide as acid absorbent, 0.3gMgAl(CO 3 )(OH)·nH 2 O is used as a metal ion trap), 1 g of vinyl ethoxysilane is used as a silane coupling agent, and 0.5 g of paraffin wax (Honeywell AC1702, softening point 90°C) is used as a stabilizer. The uniformly mixed materials are added to the melt-extrusion casting machine for extrusion, and the temperature is controlled at 100°C. The extrudate is cast, cooled, drawn, and crimped to obtain a polyolefin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com