Quantum dot and preparation method thereof

A technology for quantum dots and dispersions, applied in the field of quantum dots and their preparation, can solve the problems of high toxicity, maintain between 20-50%, low photoluminescence, etc., and achieve environmental friendliness, high monodispersity, high The effect of luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The quantum dots obtained by the above new preparation method have the following characteristics:

[0050] (1) All precursors used in the present invention are air stable.

[0051] That is to say, do not use the following precursors of ZnSe or ZnS quantum dots reported in the present invention in the new synthesis method: a, high heat precursors, such as diethylzinc, trioctylphosphine, tributylphosphine And other reagents sensitive to air or moisture; b, trioctylphosphine oxide; c, environmental reaction reagents such as hydrogen sulfide;

[0052] (2) Use weak binding ligands, such as aliphatic amines, to increase the activity of zinc precursors during the synthesis process;

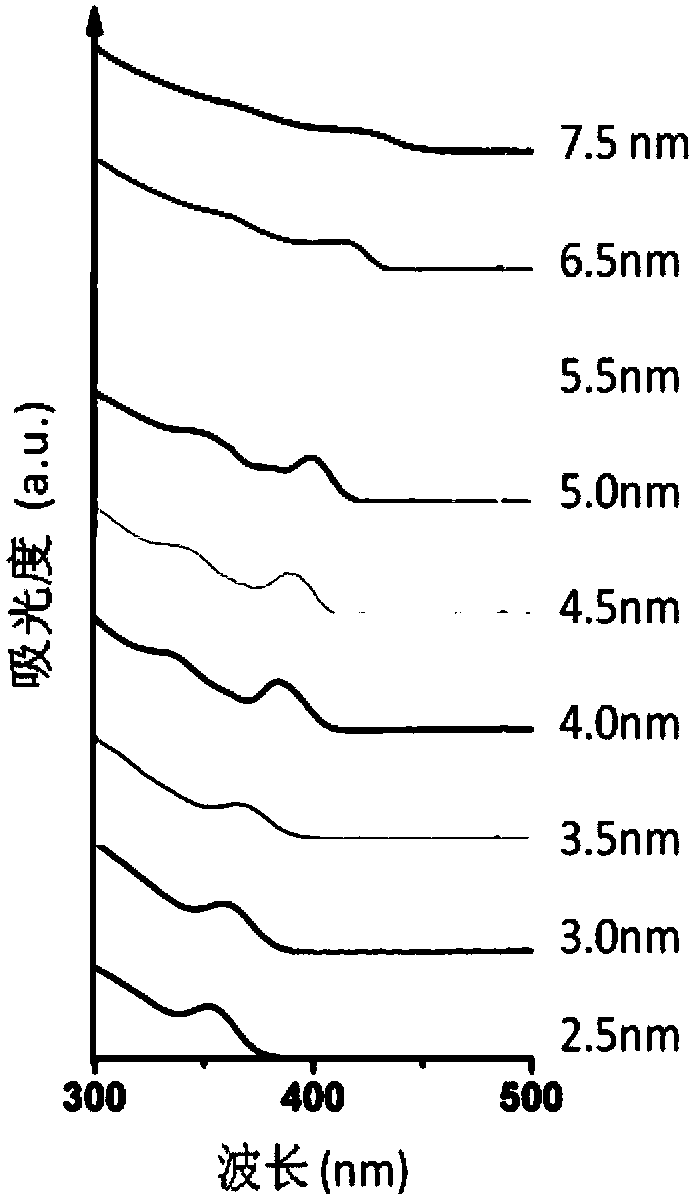

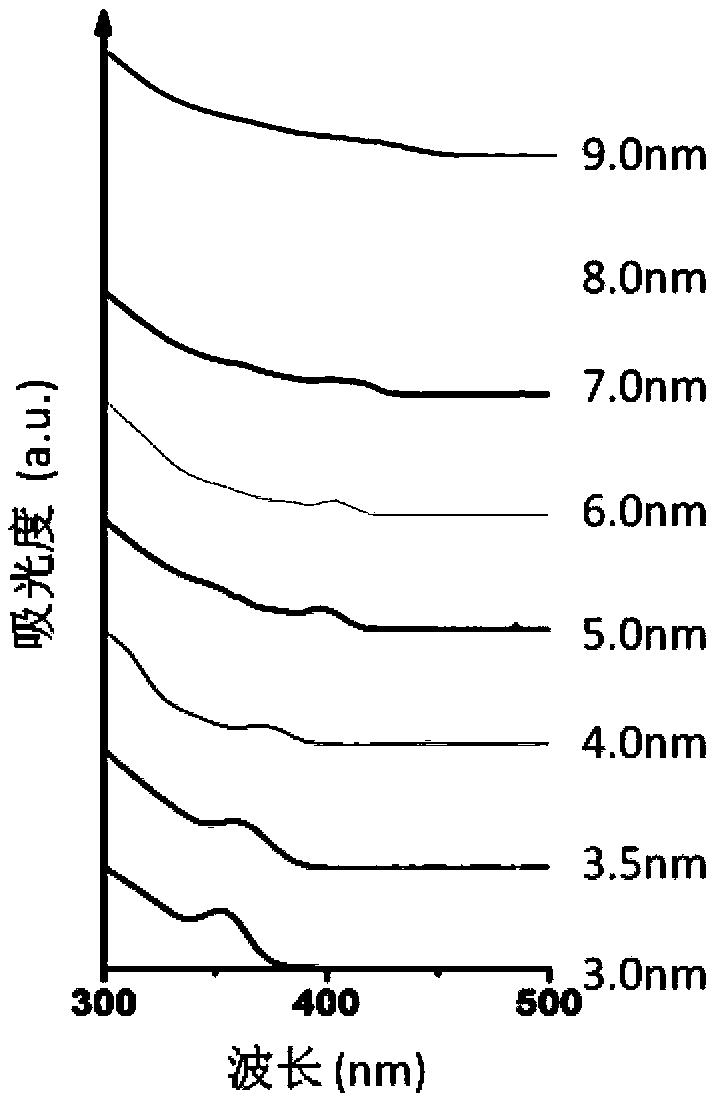

[0053] (3) The particle diameter of the prepared quantum dot product is in the scope of 2.5-9nm;

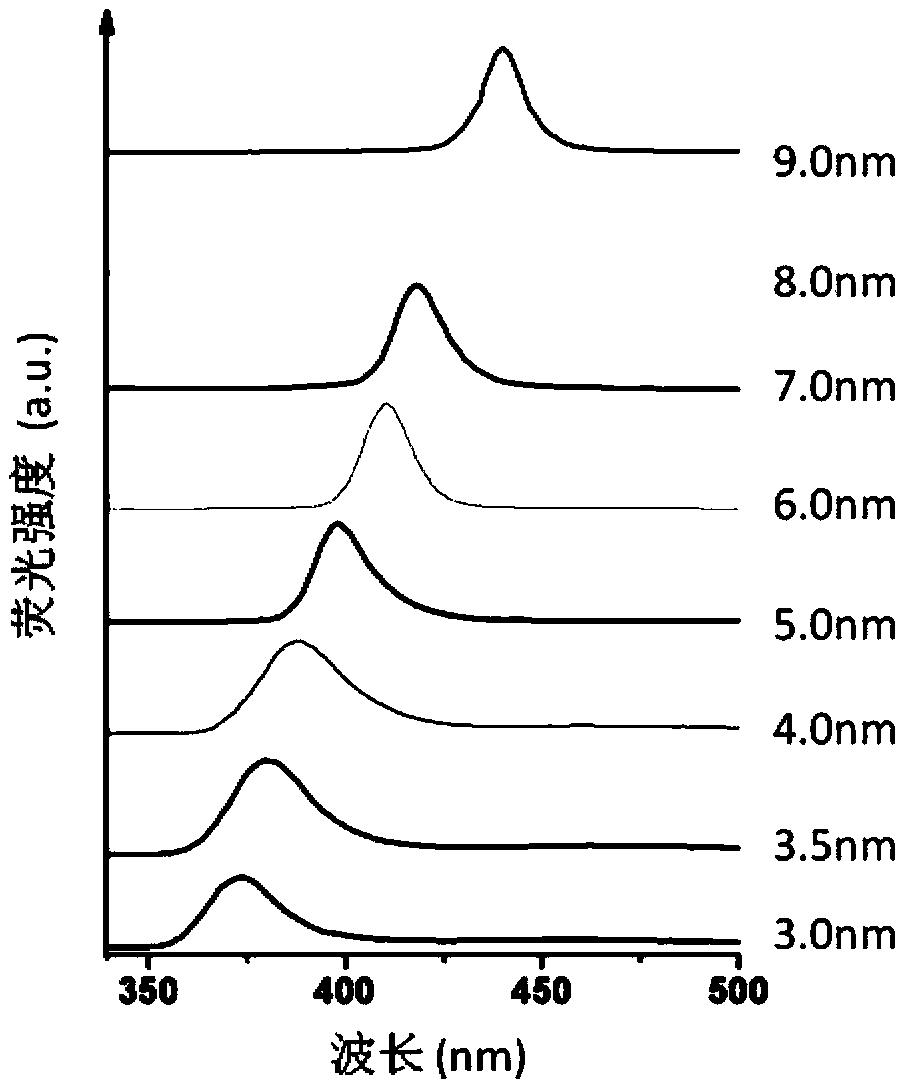

[0054] (4) The quantum dot product is excited by ultraviolet light or ultraviolet light source, and has ultraviolet photoluminescence in the range of 370-450nm. By adjusting the particle size of qu...

Embodiment 1

[0068] Preparation of ZnSe quantum dots with high monodispersity and high fluorescence:

[0069] Into a 250mL three-necked flask, add 300mg of zinc stearate, 20mL of octadecene and 0.2mL of triheptylamine, vacuumize the flask at room temperature for 30min, then heat the flask to 90°C while maintaining the vacuum for 15min, pass into argon. The flask was heated to 290°C under an argon atmosphere. Add 0.1 mL of 2 mol / L selenium dispersion solution under the protection of argon into the flask with a 1 mL syringe. Keep the flask at 290°C, cool to 260°C after 3min, and keep the temperature for 90min. At different time points, a small portion of the reaction solution was extracted for optical absorption spectrum and fluorescence spectrum test, so as to monitor the reaction process. When the quantum dots grew to the desired size, the flask was naturally cooled to room temperature. To the resulting slurry of quantum dot products was added 300 mL of methanol to induce quantum dot p...

Embodiment 2

[0072] Preparation of ZnSe quantum dot cores with high monodispersity:

[0073] Into a 100mL three-necked flask, add 300mg of zinc stearate, 6mL of octadecene and 0.2mL of triheptylamine, vacuumize the flask at room temperature for 30min, then heat the flask to 110°C while maintaining the vacuum for 15min, pass into argon. Under an argon atmosphere, the flask was heated to 290° C., and 0.2 mL of a 2 mol / L octadecene-selenium dispersion was added under the protection of argon. After 10 minutes, the flask was heated to 300°C and kept for 20 minutes. Next, raise the temperature to 310°C, keep it warm for 5 minutes, then lower the temperature to 300°C, keep it warm for 11 minutes, continue to cool down to 290°C, and keep it warm for 5 minutes. Heating was stopped, and the flask was naturally cooled to room temperature. At this time, the fluorescence emission peak is at 412nm, the half-peak width is 20.4nm, and the quantum yield is 14%.

[0074] The dispersion of core ZnSe quan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com