Low-nitrogen oxide incineration technology and device

A technology with low nitrogen oxides and nitrogen oxides, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of large equipment investment, high energy consumption, and high operating costs, saving energy consumption and increasing contact reaction time. , the effect of reducing the generation of harmful gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

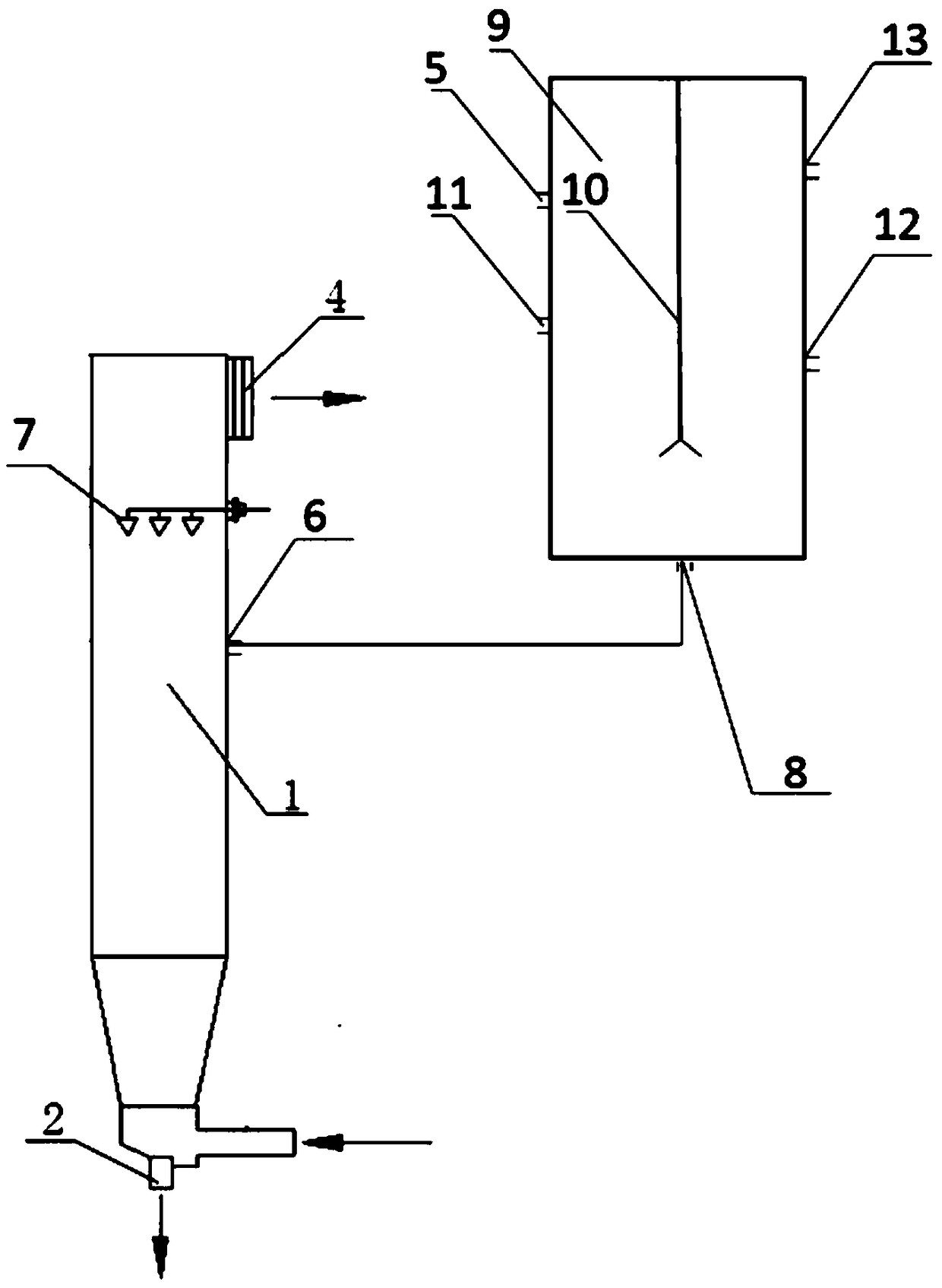

[0027] The low nitrogen oxide incineration process includes a mixing step, a limestone powder decomposition step, an ammonia gas generation step and a nitrogen oxide reduction step.

[0028] Mixing step: add the dehydrated dry mud to the mixer 9 from the first inlet 11, add the coal to the mixer 9 from the second inlet 12, add the recovered ammonium sulfate to the mixer 9 from the third inlet 13, and add the recovered ammonium sulfate to the mixer 9 from the second inlet 12. The fourth inlet 5 feeds limestone powder to the mixer 9 . Recovery of ammonium sulfate is the recovery of ammonium sulfate obtained from the treatment of high-concentration ammonium sulfate wastewater produced in the processes of ammonia desulfurization, ammonium hydrogen phosphate method to caprolactam and three-stage ammonia suction method to recover sulfuric acid tail gas. In this example, activated carbon is first added to the wastewater containing high concentration of ammonium sulfate to remove inso...

no. 2 example

[0039] The shape and structure of the low nitrogen oxide incineration device in the second embodiment are the same as those in the first embodiment, most of the steps in the low nitrogen oxide incineration process in the second embodiment The oxide incineration process is the same, and the same components use the same labels, which will not be repeated here. Only the differences are described below.

[0040] The reaction temperature range of the limestone powder decomposition step is 900°C. The amount of limestone powder added ensures that the molar ratio of calcium to sulfur is in the range of 2:1. The flue gas is controlled by controlling the input speed of limestone powder, the mixing material and the exhaust gas. The contact reaction time with ammonia gas is 5s.

no. 3 example

[0042] The low nitrogen oxide incineration device in the third embodiment has the same shape and structure as that in the first embodiment, and most of the steps in the low nitrogen oxide incineration process in the third embodiment are the same as those in the first embodiment. The oxide incineration process is the same, and the same components use the same labels, which will not be repeated here. Only the differences are described below.

[0043] The reaction temperature range of the limestone powder decomposition step is 900°C. The amount of limestone powder added ensures that the molar ratio of calcium to sulfur is in the range of 2:1. The flue gas is controlled by controlling the input speed of limestone powder, the mixing material and the exhaust gas. The contact reaction time with ammonia gas is 6s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com