Extracting desulfurizing agent, preparation method thereof and desulfurizing refining method for biodiesel oil

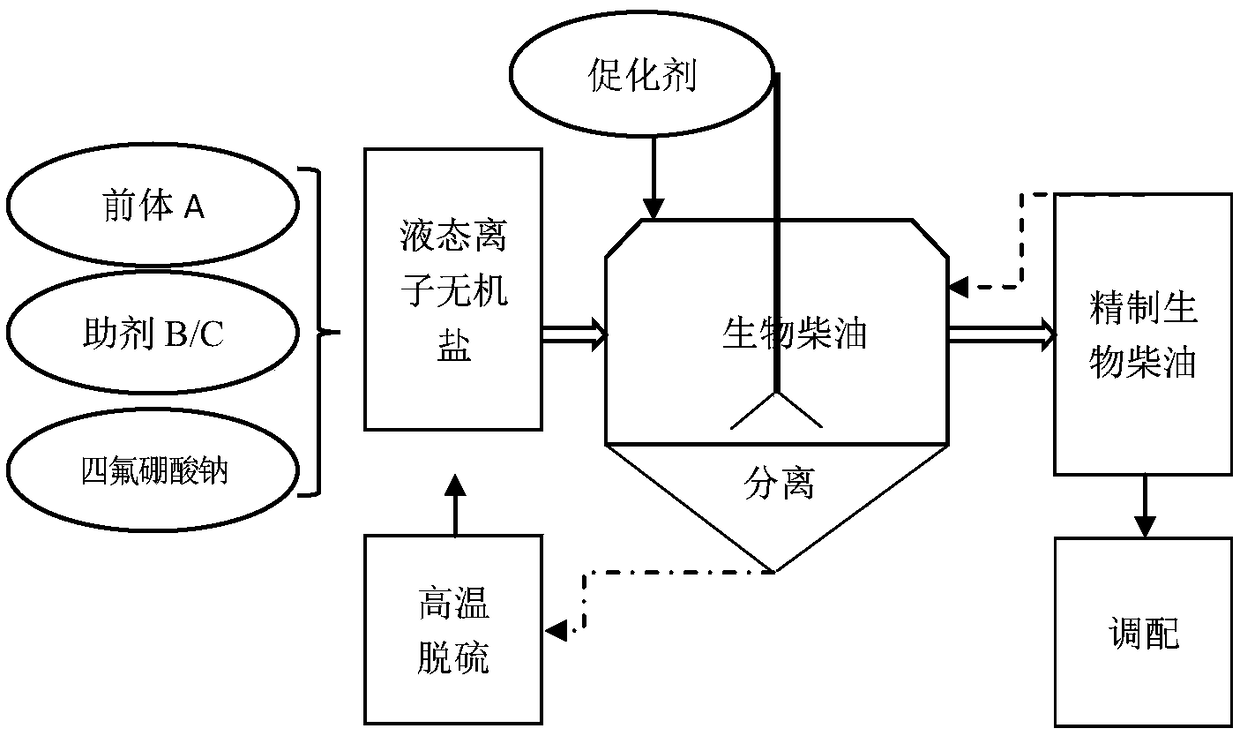

The technology of a biodiesel and a refining method is applied in the field of deep processing of biomass energy liquid fuel, which can solve the problems of pollution, high energy consumption and high refining consumption, and achieve the effects of simple process, low energy consumption and low refining consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Further, the present invention also provides a method for preparing the above-mentioned extractive desulfurizer, the method comprising the following steps:

[0043] (1) Preparation of precursor A: 1-methylimidazole and n-bromobutane or bromopropane are stirred and reacted according to the mass ratio of 30-50:40-60. Place until a white solid is precipitated, then recrystallize with auxiliary agent B, and dry by rotary evaporation to obtain white solid precursor A; the components of said auxiliary agent B include: 20-40 parts of acetonitrile, 20-40 parts of ethyl acetate and 20 ~30 parts of acetone;

[0044] (2) Under the condition of stirring, put the above precursor A and sodium tetrafluoroborate in an acetone solvent according to the mass ratio of 40~50:50~70 to react to obtain a yellow viscous liquid, and the obtained liquid is washed with auxiliary agent C, spin steaming to obtain a bright yellow clear product; the composition of the auxiliary agent C includes: 40-6...

preparation example 1

[0064] The extractive desulfurizer is prepared by the following steps:

[0065] The composition of precursor A includes: 45 parts of 1-methylimidazole, 55 parts of n-bromobutane or bromopropane.

[0066] The composition of auxiliary agent B includes: 40 parts of acetonitrile, 40 parts of ethyl acetate and 20 parts of acetone.

[0067] The composition of auxiliary agent C (stabilizer C) includes: 50 parts of dichloromethane, 50 parts of chloroform.

[0068] Precursor A, sodium tetrafluoroborate (1.2 times the molar mass of Precursor A) and acetone of 1 / 3 of the total mass of raw materials were used as a solvent for the reaction, and electromagnetic stirring was performed at 20°C for 15 hours to obtain a yellow viscous liquid. The resulting liquid was washed twice with 3 times the volume of auxiliary agent C. The yellow viscous liquid was rotary evaporated under vacuum at 80 °C for 60 min to obtain a bright yellow clear product.

Embodiment 1

[0069] Example 1 Biodiesel desulfurization and refining method-extraction desulfurization process

[0070] The biodiesel produced from gutter oil raw material has a sulfur content of 1.73mg / L.

[0071] In a reactor with an interlayer, the raw material biodiesel was preheated to 120° C., and there was no residual methanol and water after vacuum distillation for 2 hours. The raw material biodiesel is cooled to 50° C., and a liquid ionic inorganic salt with a mass fraction of 18% is added. Stir continuously at 800r / min for 100min, during which 0.5% mass fraction of hydrogen peroxide is added dropwise as a catalyst for the extraction reaction. After the reaction is completed, the biodiesel is separated after standing and stratified, and the lower liquid ionic inorganic salt is recovered. The extraction and desulfurization were repeated 3 times under the same conditions.

[0072] After testing, the sulfur content of refined biodiesel was 0.14mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com