Main chain benzoxazine copolymer oligomer containing polystyrene, copolymer resin and preparation method thereof

A technology of benzoxazine copolymer resin and polystyrene, which is applied in the field of organic polymer materials, can solve the problems that cannot meet the requirements well, and achieve the effect of improving dielectric properties, improving thermal stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

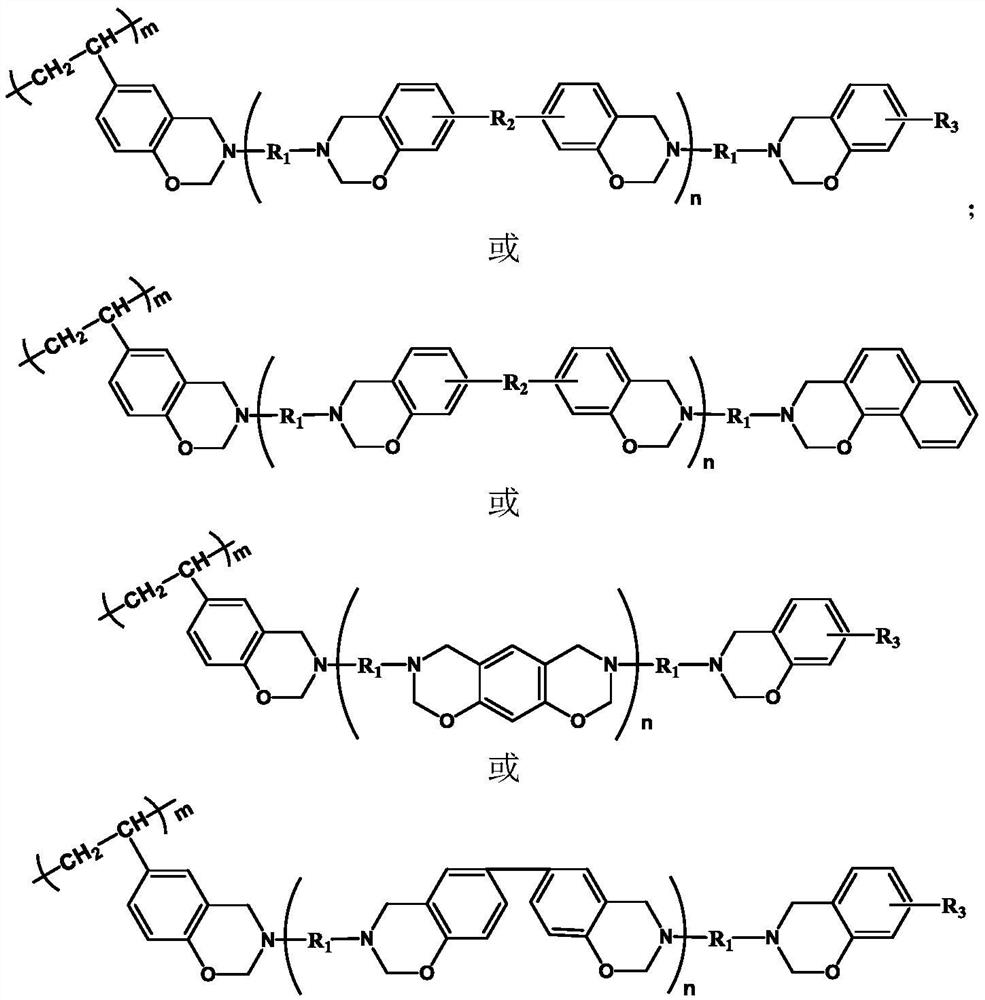

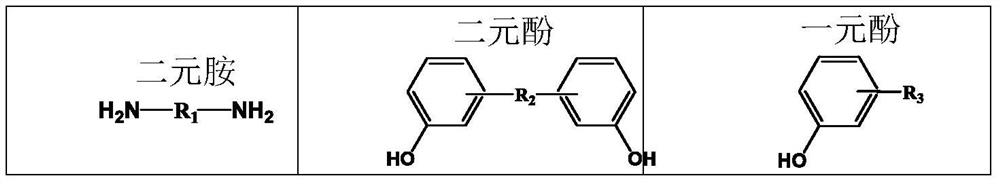

Method used

Image

Examples

Embodiment 1

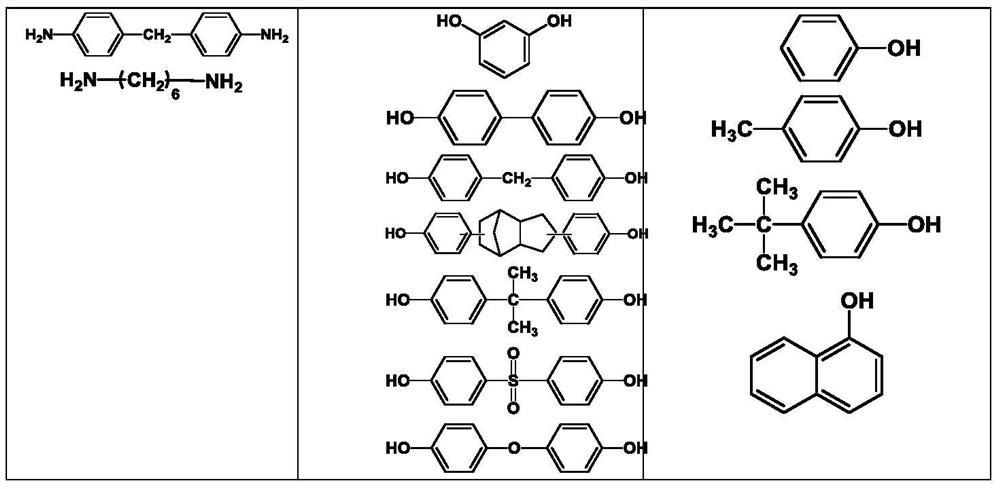

[0031] Add 0.05mol 4,4'-diaminodiphenylmethane and 0.2mol paraformaldehyde into a three-necked flask equipped with a condenser, magnetic stirring, and a thermometer, and add 60mL of toluene / N,N'-dimethylformamide mixed solvent (Volume ratio is 1:1), heated to 105°C and stirred for 60 minutes, then introduced nitrogen gas, added 0.025mol resorcinol, stirred for another 60 minutes, added 0.025mol p-cresol and 0.025mol poly-p-vinylphenol, aldehyde group , The molar ratio of phenolic hydroxyl group and amino functional group is 2:1:1, and then continue to react for 72h. After the reaction, pour the reaction solution into 100mL methanol solution (concentration 85wt%) and let it stand for 24h to obtain a precipitate. Vacuum drying for 6 hours, and finally grinding the dried product to obtain a powder which is the main chain benzoxazine copolymer oligomer.

[0032] The molecular structural formulas of 4,4'-diaminodiphenylmethane, resorcinol and p-cresol used in this example are respe...

Embodiment 2

[0039] Add 0.05mol 4,4'-diaminodiphenylmethane and 0.2mol paraformaldehyde into a three-necked flask equipped with a condenser, magnetic stirring, and thermometer, and add 60mL of xylene / methanol mixed solvent (volume ratio 3:1) . After heating to 120°C and stirring for 60 minutes, nitrogen gas was introduced, 0.025mol of 4,4'-dihydroxybiphenyl was added, and after stirring for 100 minutes, 0.025mol of phenol and 0.025mol of poly-p-vinylphenol were added, and the molar ratio of aldehyde groups, phenolic hydroxyl groups and amino functional groups 2:1:1, and then continue to react for 36 hours. After the reaction, pour the reaction solution into 100mL methanol solution (concentration 95wt%) and let it stand for 24 hours to obtain a precipitate. Vacuum dry the precipitate at 60°C for 6 hours, and finally dry it The powder obtained by grinding the product is the main chain benzoxazine copolymer oligomer.

[0040] The molecular structural formulas of 4,4'-diaminodiphenylmethane, ...

Embodiment 3

[0047] Add 0.05mol 1,6-hexamethylenediamine and 0.2mol paraformaldehyde into a 250mL three-neck flask equipped with a condenser, magnetic stirring, and a thermometer, add 60mL of toluene / ethanol mixed solvent (volume ratio: 1:5), and heat Stir at 80°C for 60min. After feeding nitrogen, add 0.025mol bisphenol A, stir for another 120min, add 0.025mol phenol, 0.025mol poly-p-vinylphenol, the molar ratio of aldehyde group, phenolic hydroxyl group and amino functional group is 2:1:1, and then continue to react for 100h After the reaction, pour the reaction liquid into 100mL methanol solution (concentration 60wt%), let it stand for 24 hours to obtain a precipitate, dry the precipitate in vacuum at 50°C for 24 hours, and finally grind the dried product to obtain a powder that is polystyrene End-capped backbone benzoxazine copolymer oligomer.

[0048] The molecular structural formulas of 1,6-hexamethylenediamine, bisphenol A and phenol used in this embodiment are respectively:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com