A kind of polyimide dielectric film and its preparation method and application

A technology of polyimide film and polyimide electricity is applied in the field of high temperature resistant polyimide dielectric film for film capacitors and its preparation, which can solve the problems of low g and the like, and achieve high dielectric constant and low dielectric Loss, the effect of highlighting heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

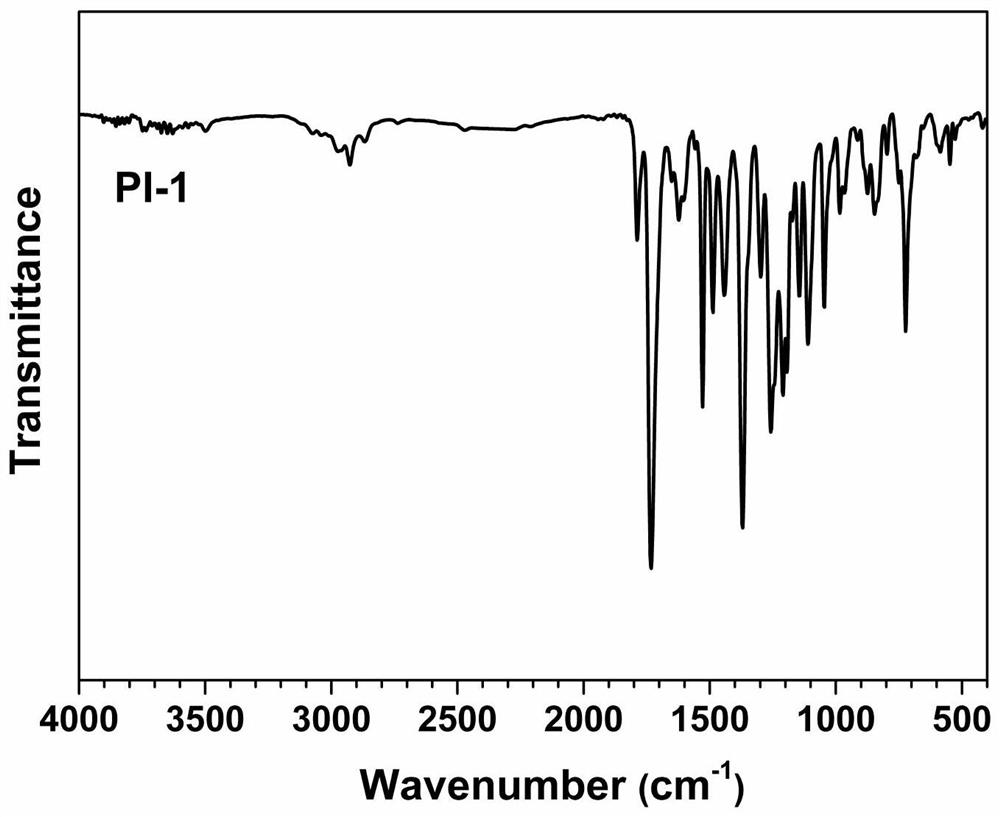

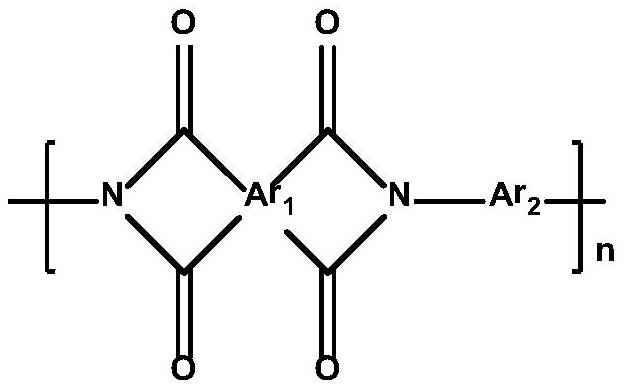

[0044] Embodiment 1, the preparation of polyimide dielectric film

[0045] At room temperature and normal pressure, in a three-neck round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 1.9623 grams of 0.0098 moles of 4,4'-diaminodiphenyl ether and 40.1 grams of N-methylpyrrolidone (NMP), Stir under nitrogen protection until completely dissolved, add 2.4922 grams of 0.01 mole 3,3',4,4'-biphenyltetraacid dianhydride to obtain a homogeneous solution with a solid content of 10wt.%, and continue to react for 6 hours to obtain Polyamic acid solution.

[0046] After the above polyamic acid solution is filtered and vacuum degassed, it is coated on a glass plate with a smooth surface. The temperature is raised in the step of ℃, an imidization reaction occurs, and a polyimide film is obtained. Place the glass plate in deionized water to peel off the film automatically, and dry it in vacuum to obtain a polyimide dielectric film with a thickness of...

Embodiment 2

[0049] Embodiment 2, the preparation of polyimide dielectric film

[0050] At room temperature and normal pressure, in a three-necked round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 1.9826 grams of 0.01 mole 4,4'-diaminodiphenylmethane and 28.8 grams of dimethyl sulfoxide (DMSO), Stir under nitrogen protection until completely dissolved, then add 3.1020 grams of 0.01 mole 3,3',4,4'-diphenyl ether tetraacid dianhydride to obtain a homogeneous solution with a solid content of 15wt.%, and continue the reaction for 8 hours to obtain a polyamic acid solution.

[0051] After the above polyamic acid solution is filtered and vacuum defoamed, it is coated on a silicon wafer with a smooth surface. °C, 250 °C for 1 hour, and 300 °C for 0.5 hour, and the imidization reaction occurred to obtain a polyimide film. The silicon wafer was placed in deionized water to peel off the film automatically, and dried in vacuum to obtain a polyimide dielectr...

Embodiment 3

[0053] Embodiment 3, preparation and characterization of polyimide dielectric film

[0054] At room temperature and normal pressure, in a three-neck round-bottomed flask equipped with mechanical stirring and a nitrogen inlet and outlet, add 3.5571 grams of 0.0095 moles of 1,4-bis(4-aminobenzoic acid) hydroquinone ester and dimethyl sulfoxide ( DMSO) and N,N-dimethylformamide (DMF) mixed solvent 20.3 grams, volume ratio DMSO:DMF=1:1, stirred under nitrogen protection until completely dissolved, added 3.2223 grams of 0.01 mole of 3,3', 4,4'-benzophenonetetraacid dianhydride to obtain a homogeneous solution with a solid content of 25 wt.%, and continue to react for 6 hours to obtain a polyamic acid solution.

[0055] After the above polyamic acid solution is filtered and vacuum degassed, it is coated on a glass plate with a smooth surface. The temperature is raised in the step of ℃, an imidization reaction occurs, and a polyimide film is obtained. Place the glass plate in deion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| breakdown field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com