Freeze-drying powder for improving dry and sensitive skin and preparation method thereof

A technology of freeze-dried powder and solvent, which is applied in the field of cosmetics, can solve the problems of not being able to guarantee whether there is still activity, not being able to improve the skin in an all-round way, and discounting product effects, so as to relieve skin redness, relieve seborrheic dermatitis, and ensure dispersion Effects of Sex and Uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

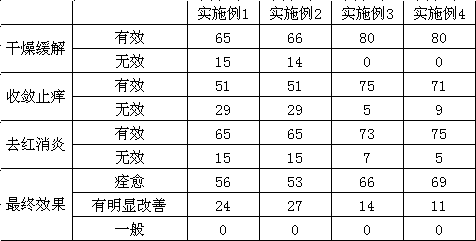

Embodiment 1

[0028] A kind of freeze-dried powder, its preparation steps are as follows:

[0029] (1) Weigh the following raw materials: 0.1 g of milk immune protein, 1 g of tetrahydromethyl pyrimidine carboxylic acid, 6 g of mannitol, and 85 g of phosphate buffer solution with a pH value of 6.8;

[0030] (2) Pre-disperse milk immune protein in an equal amount of glycerol, then add phosphate buffer, stir for 1 hour, and wait until the solution is translucent and free of granular substances; then add mannitol, tetrahydromethyl pyrimidine carboxylic acid , stirring and dissolving to obtain a mixed solution;

[0031] (3) Pre-freeze the prepared mixed solution in a -80°C refrigerator for 24 hours, then transfer to a vacuum freeze dryer for freeze-drying, turn off the machine after 48 hours, and take out the freeze-dried powder.

Embodiment 2

[0033] A kind of freeze-dried powder, its preparation steps are as follows:

[0034] (1) Weigh the following raw materials: 2 g of milk immune protein, 0.1 g of tetrahydromethyl pyrimidine carboxylic acid, 4 g of mannitol, and 95 g of phosphate buffer solution with a pH value of 7.4;

[0035] (2) Pre-disperse milk immune protein in an equal amount of glycerol, then add phosphate buffer, stir for 0.5 hours, and wait until the solution is translucent and free of granular substances; then add mannitol, tetrahydromethylpyrimidine carboxylate acid, stirring and dissolving to obtain a mixed solution;

[0036] (3) Pre-freeze the prepared mixed solution in a -80°C refrigerator for 48 hours, then transfer to a vacuum freeze dryer for freeze-drying, turn off the machine after 24 hours, and take out the freeze-dried powder.

Embodiment 3

[0038] (1) Weigh the following raw materials: 1 g of milk immune protein, 0.5 g of tetrahydromethylpyrimidine carboxylic acid, 4 g of mannitol, 1 g of trehalose, 1 g of glycine, and 92.5 g of phosphate buffer with a pH value of 6.8;

[0039] (2) Pre-disperse the milk immune protein in an equal amount of glycerol, then add phosphate buffer, stir for 0.5 hours, and wait until the solution is translucent and free of granular substances; then add mannitol, trehalose, glycine, four Hydromethylpyrimidine carboxylic acid, stirring and dissolving; finally adding the cell repair factor and stirring evenly to prepare a mixed solution, wherein the active concentration of the cell repair factor in the solution is 100 IU / mL;

[0040] (3) Pre-freeze the prepared mixed solution in a -80°C refrigerator for 48 hours, then transfer to a vacuum freeze dryer for freeze-drying, turn off the machine after 24 hours, and take out the freeze-dried powder.

[0041]The cell repair factor described in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com