Polymer shell coating material, polymer coating slow-release inorganic salt and preparation methods thereof

A technology of polymers and cladding materials, applied in chemical instruments and methods, and other chemical processes, can solve problems such as waste of resources, environmental pollution, and no research on material temperature control, and achieve the effect of lowering the freezing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Polymer Shell Covering Material

[0031] Follow the steps below:

[0032] 1. Mix 1-2g of acrylic acid, 20-24g of methyl acrylate, 15-20g of butyl acrylate, and 8-10g of styrene to prepare a polymer monomer solution.

[0033] 2. Take a four-neck flask, add 44-84g of isopropanol or propylene glycol methyl ether solution into it, connect it to a condenser, and stir in an oil bath at 100-140°C.

[0034] 3. Mix the polymer monomer solution prepared in step 1 with 1-4g KH570 (silane coupling agent), 0.8-1.0g AIBN (azobisisobutyronitrile) and add it dropwise to step 2 through a separatory funnel. In the four-necked flask with isopropanol or propylene glycol methyl ether, the dropwise addition time is 2.5-3.5 hours, then keep warm for 0.7-1.3 hours, and finally add 0.08-0.12 parts of AIBN and 2-3 parts of isopropanol or propylene glycol methyl ether, Continue to stir for 0.8 to 1.5 hours, lower the temperature to 40 to 60°C, then add 2 to 4 parts of t...

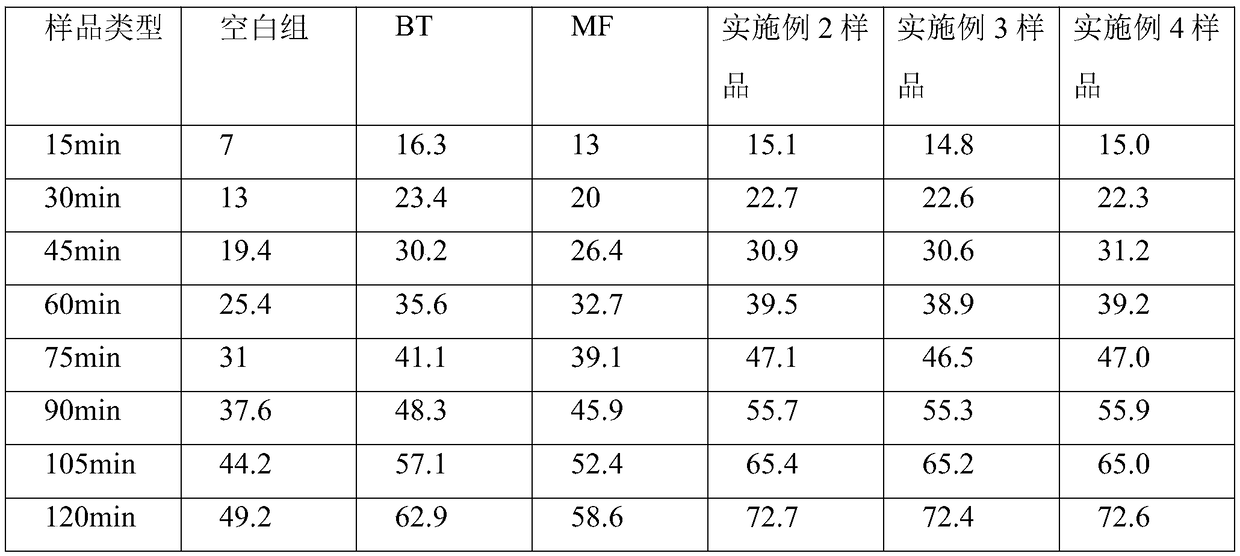

Embodiment 2

[0035] Example 2 Preparation of polymer-encapsulated slow-release inorganic salt

[0036] Follow the steps below:

[0037] 1. Preparation of slow-release inorganic salt core material

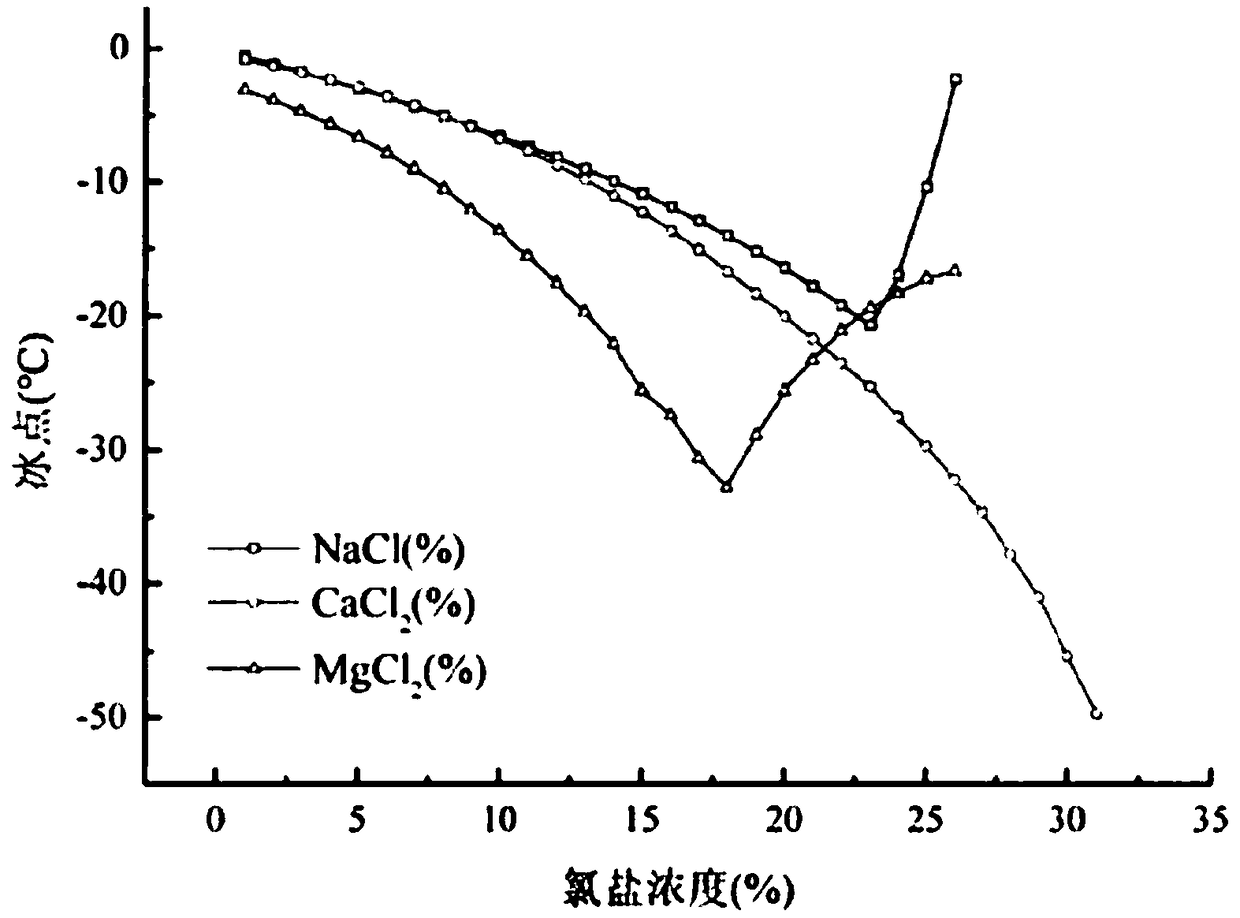

[0038] 1. First prepare 100g of calcium chloride saturated solution.

[0039] 2. Mix 8g of diatomite, 0.8g of nano silicon dioxide, 3g of surfactant op-10, and 140g of absolute ethanol in a four-necked flask, place the four-necked flask in a 50°C water bath, and then stir Stir with a polytetrafluoroethylene stirring rod under a container to prepare a nano-silica-modified diatomite suspension.

[0040] 3. Add the saturated calcium chloride solution dropwise to the diatomite suspension prepared in step 2 through a separatory funnel, and stir after the dropwise addition to obtain a mixed solution.

[0041] 4. Vacuum filter the mixed solution prepared in step 3, then put it into an oven for drying, and then pulverize it into powder with a mortar to obtain the slow-release inorganic salt core mate...

Embodiment 3

[0048] Example 3 Preparation of polymer-encapsulated slow-release inorganic salt

[0049] Follow the steps below:

[0050] 1. Preparation of slow-release inorganic salt core material

[0051] 1. First prepare 110 g of magnesium chloride saturated solution.

[0052] 2. Mix 9g of diatomite, 1.2g of nano silicon dioxide, 5g of surfactant op-8, and 160g of absolute ethanol in a four-necked flask, place the four-necked flask in a 70°C water bath, and then stir Stir with a polytetrafluoroethylene stirring rod under a container to prepare a nano-silica-modified diatomite suspension.

[0053] 3. Add the saturated magnesium chloride solution dropwise to the diatomite suspension prepared in step 2 through a separatory funnel, and stir after the dropwise addition to obtain a mixed solution.

[0054] 4. Vacuum filter the mixed solution prepared in step 3, then put it into an oven for drying, and then pulverize it into powder with a mortar to obtain the slow-release inorganic salt core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

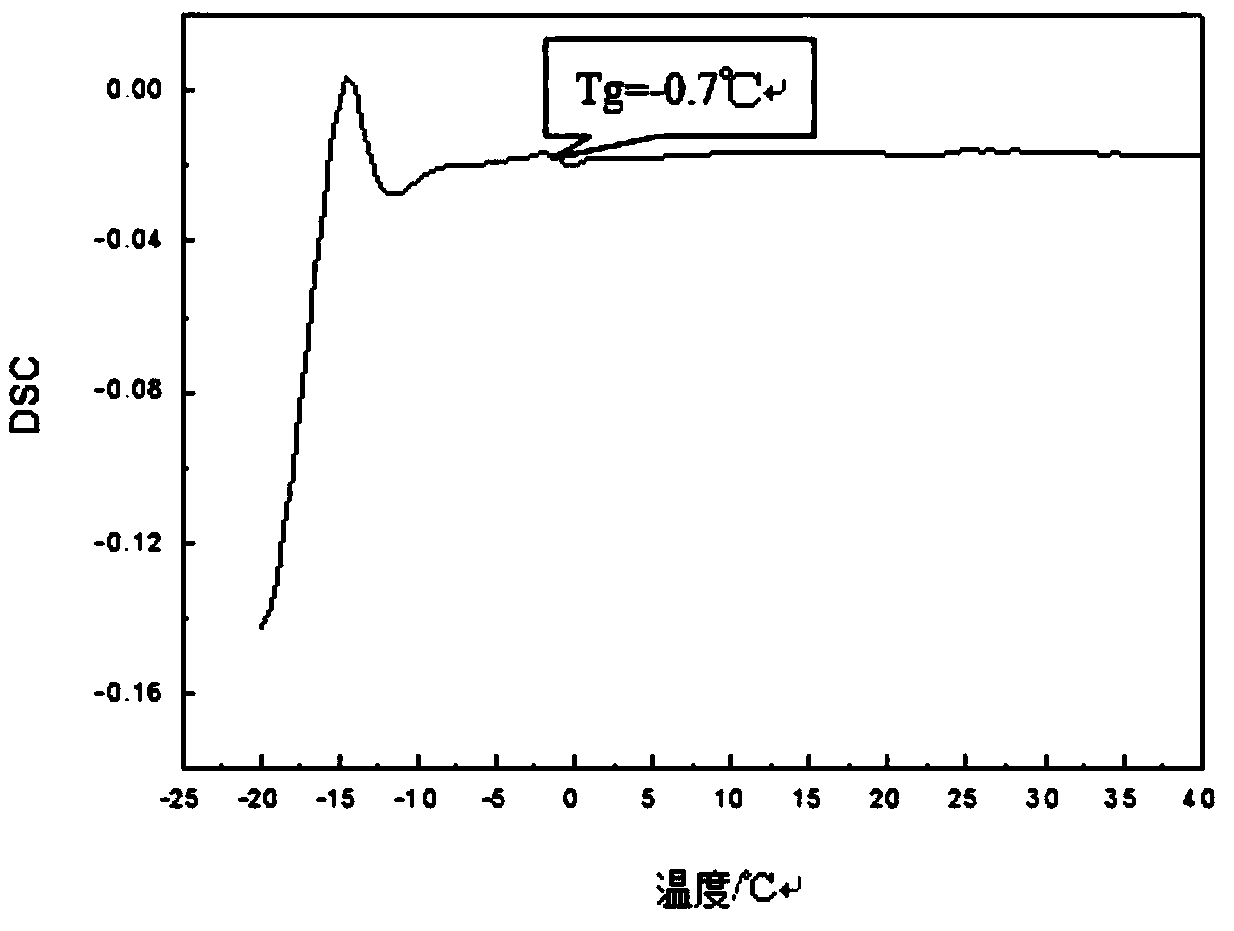

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com