SnO2-ZnO gas sensitive material with heterostructure and preparation method thereof

A technology of gas-sensing materials and heterogeneous structures, which is applied in the fields of analysis of materials, material resistance, and material analysis through electromagnetic means, which can solve the problems of limited improvement of gas-sensing performance, complicated process, and inability to fully utilize the synergistic effect of ZnO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0030] According to one aspect of the present invention, the present invention proposes a method for preparing heterostructured SnO 2 -The method of ZnO gas sensitive material, according to the specific embodiment of the present invention, this method comprises: (1) adds organic weak base to tin tetrachloride ethanol solution, adjusts pH to 8-10, and carries out aging, so that obtain Tin sol; (2) ZnO nanowires are dispersed in the tin sol, and hexamethylenetetramine is added to obtain a preliminary reaction solution; (3) the preliminary reaction solution is placed in an autoclave for reaction , and the reaction product is filtered, washed and dried in order to obtain the heterostructured SnO 2 -ZnO gas sensitive material.

[0031] The preparation of heterostructured SnO in the foregoing embodiments of the present invention 2 - Modified SnO by in-situ growth on the surface of ZnO nanowires in the method of ZnO gas-sensing materials 2 Nanoparticles, which significantly increa...

Embodiment 1

[0064] (1) SnO with heterostructure 2 -ZnO gas sensitive material:

[0065] Preparation of tin sol: Add 0.05 mol / L methyl triethyl ammonium hydroxide aqueous solution dropwise to 0.02 mol / L tin tetrachloride ethanol solution until the pH of the system is ~9; and age at 50°C for 3 hours Obtain tin sol. Disperse 0.81g of ZnO nanowires in the above tin sol, add 0.14g of hexamethylenetetramine, then transfer the mixed solution to a hydrothermal reaction kettle, react at 160°C for 10h, filter, wash and dry to obtain Heterostructured SnO 2 -ZnO gas sensitive material.

[0066] (2) Analysis test:

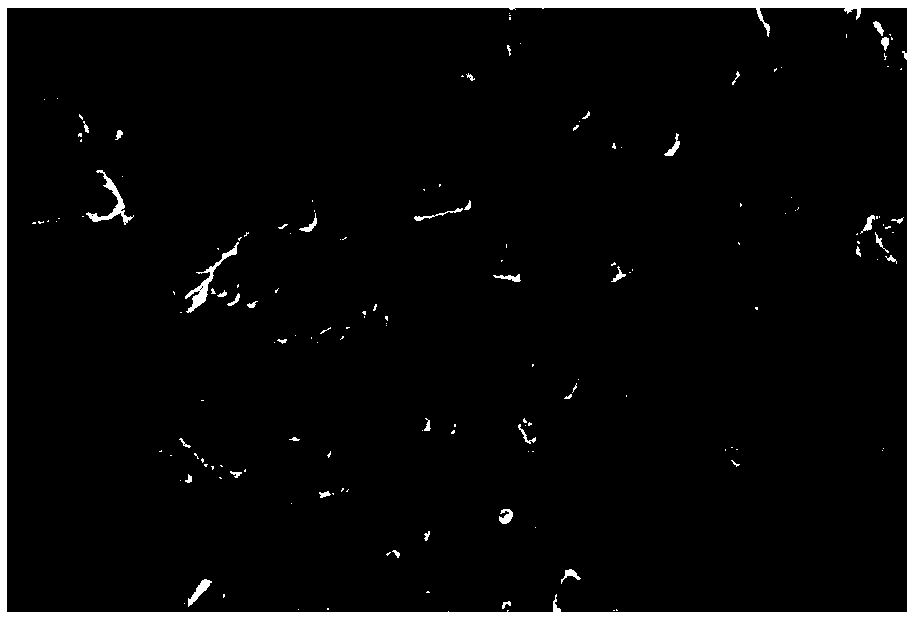

[0067] For the prepared heterostructured SnO 2 -ZnO gas sensitive material was observed under the scanning electron microscope, the results are shown in figure 2 .

[0068] The prepared sensitive material is made into a gas sensor element, and the performance is tested on a WS-30A gas sensor tester, and the test method is the same as that of the comparative example.

[0069] (3) C...

Embodiment 2

[0073] (1) Add 0.05mol / L methyltriethylammonium hydroxide aqueous solution dropwise to 0.03mol / L tin tetrachloride ethanol solution until the pH of the system is ~9; and age at 50°C for 3h to obtain tin sol. Disperse 0.61g of ZnO nanowires in the above tin sol, and add 0.42g of hexamethylenetetramine, then transfer the mixed solution to a hydrothermal reaction kettle, react at 160°C for 10h, filter, wash and dry to obtain Heterostructured SnO 2 -ZnO gas sensitive material.

[0074] (2) Analysis test:

[0075] For the prepared heterostructured SnO 2 -ZnO gas sensitive material was observed under the scanning electron microscope, the results are shown in image 3 .

[0076] (3) Conclusion:

[0077] Depend on image 3 shows that the prepared heterostructured SnO 2 -ZnO surface modified SnO 2 The particle size of nanoparticles is about 20nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com