Composite coated positive electrode active material and preparation method thereof, lithium ion battery positive electrode material and solid lithium ion battery

A positive electrode active material and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cycle stability and poor rate performance, achieve inhibition of dissolution and phase transition, avoid element diffusion, improve The effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to a second aspect of the present invention, the present invention provides a method for preparing the above-mentioned composite coated positive electrode active material, comprising the steps of:

[0040] The titanium alkoxide, graphene oxide and positive electrode active material are uniformly mixed in a solvent, and hydrolysis and solvothermal reaction are carried out to obtain a composite coated positive electrode active material.

[0041] The preparation method of the composite coating positive electrode active material provided by the present invention is to obtain the composite coating positive electrode active material by mixing titanium alkoxide, graphene oxide and positive electrode active material and then performing hydrothermal and solution thermal reactions. The process is simple and the coating Uniform, suitable for large-scale production.

[0042] In a preferred embodiment of the present invention, the titanium alkoxide and graphene oxide are f...

Embodiment 1

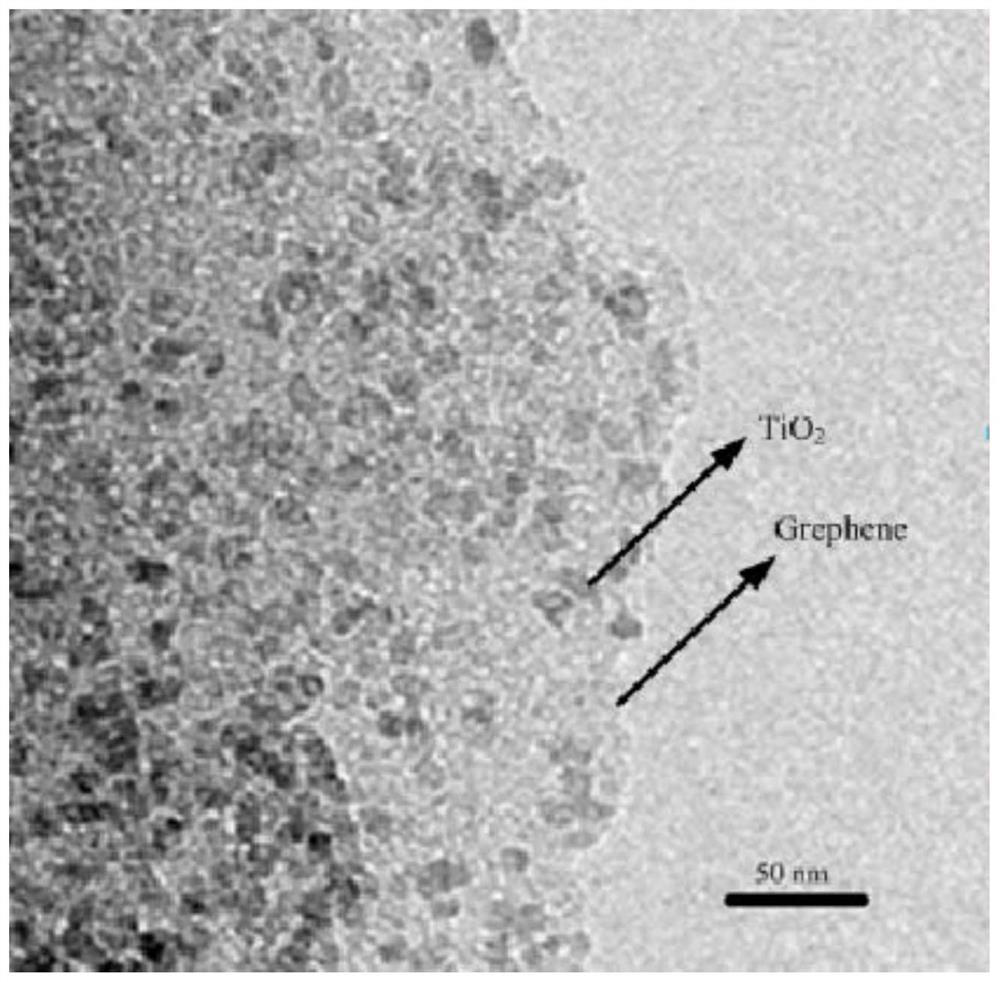

[0068] The present embodiment provides a composite coated positive electrode active material, which includes lithium nickel cobalt manganese oxide, titanium dioxide and graphene, and the mass ratio of the three is 92:7:1, the thickness of the composite material layer is 50nm, and its specific structure The surface of nickel cobalt lithium manganate is coated with a composite material layer, the composite material layer includes titanium dioxide and graphene, and titanium dioxide is grown on the sheet of graphene in situ;

[0069] The preparation method of the composite coated positive electrode active material comprises the following steps:

[0070] (1) Weigh 50mg of polyethylene glycol, dissolve it in 20mL (concentration 95%) ethanol solution under the condition of 70°C water bath, then add 0.2g graphene oxide for ultrasonic dispersion for 1h, measure 3mL (relative density 0.996g / mL) of tetrabutyl titanate and 1 mL (99.8% purity) of acetylacetone were added to a beaker, and ...

Embodiment 2

[0073] This embodiment provides a composite coated positive electrode active material, the structure of which is the same as that of the composite coated positive electrode active material provided in Example 1, except that the mass ratio of nickel cobalt lithium manganate, titanium dioxide and graphene is 99% :0.5:0.5, the composite layer thickness is 5nm;

[0074] The preparation method of the composite coated positive electrode active material provided in this example is the same as that of Example 1, except that the amount of raw materials is different, wherein the amount of nickel-cobalt lithium manganese oxide is 9.9g, and the amount of tetrabutyl titanate is 0.25mL (relative density 0.996g / mL), the amount of graphene oxide is 0.1g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com