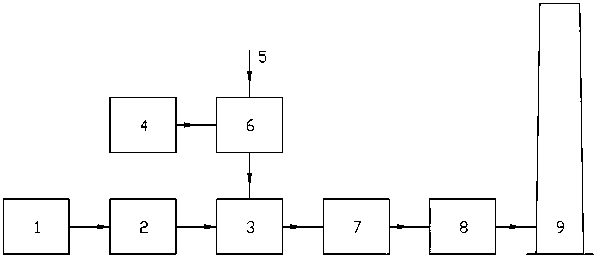

Low-temperature SCR denitration treatment method and device

A treatment method, low-temperature denitrification technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve problems such as easy poisoning and deactivation of low-temperature SCR catalysts, affecting denitrification efficiency and service life, and difficulties in the application of SCR technology. Achieve the effect of reducing denitrification cost, reducing replacement frequency, and good low-temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (1)Al 2 o 3 Preparation of sol: Add pseudo-boehmite to deionized water, add concentrated nitric acid dropwise while stirring, heat to 50-90°C, add nitric acid dropwise until completely peptized, control the pH value of the solution to 2-5, and age After 12-48 hours, a transparent aluminum sol was obtained. The mass ratio of pseudo-boehmite to deionized water is 1:2-1:10, and the mass ratio of concentrated nitric acid to pseudo-boehmite is 1:5-3:5.

[0031] (2)Al 2 o 3 Preparation of the coating: the honeycomb ceramic substrate is immersed in Al 2 o 3 Immerse in the sol for 3-10 minutes, after taking it out, blow off the residual liquid in the channel with compressed air, dry and roast to obtain Al-coated 2 o 3 Coated carrier. The honeycomb ceramic matrix is a cordierite honeycomb ceramic matrix.

[0032] (3) TiO 2 - Preparation of molecular sieve composite slurry: TiO with anatase structure 2 Mix the powder with molecular sieve and urea, add Al 2 o 3 Sol,...

Embodiment 1

[0038] After the flue gas of a coal-fired boiler is pretreated by dust removal and heated to 150 °C, the relevant parameters of the flue gas are shown in Table 1.

[0039] Table 1 Flue gas composition of a coal-fired boiler

[0040]

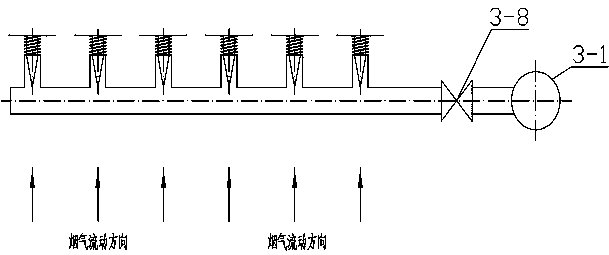

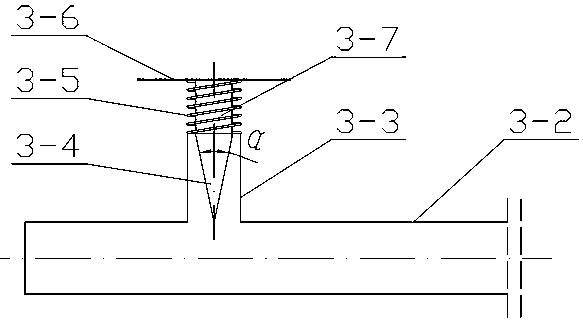

[0041] The low-temperature denitration catalyst prepared by CN201510801022.2 Example 1-4 is marked as A-D catalyst, loaded in the SCR denitration reactor, and the operating space velocity is 4800h -1 . With hot air as the dilution gas, the volume concentration of ammonia in the diluted ammonia gas is 3.5v%. The ammonia injection grid adopts the ammonia injection grid commonly used in this field. The final catalyst composition (based on the mass of the honeycomb ceramic substrate) and the treatment effect are shown in Table 2.

[0042] Table 2 Composition and treatment effect of low-temperature denitrification catalyst

[0043]

Embodiment 2

[0045] After the regenerated flue gas of a catalytic cracking unit is pretreated by dedusting and heated to 180 °C, the relevant parameters of the flue gas are shown in Table 3.

[0046] Table 3 Flue gas composition of a coal-fired boiler

[0047]

[0048] Using the same catalysts A-D as in Example 1, packed in the SCR denitrification reactor, the denitrification reactor operates at a space velocity of 5400h -1 . With hot air as the dilution gas, the volume concentration of ammonia in the diluted ammonia gas is 3.0v%. The ammonia injection grid adopts the ammonia injection grid commonly used in this field. The treatment effect is shown in Table 4.

[0049] Table 4 Treatment Effects of Different Catalysts

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com