Oil paint for ships and production method thereof

A paint and ship technology, applied in the field of ship paint and its production, can solve the problems of poor coating hardness, damage, and wear of the hull surface coating, and achieve the effects of low wear, improved fluidity, and prevention of electrochemical corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

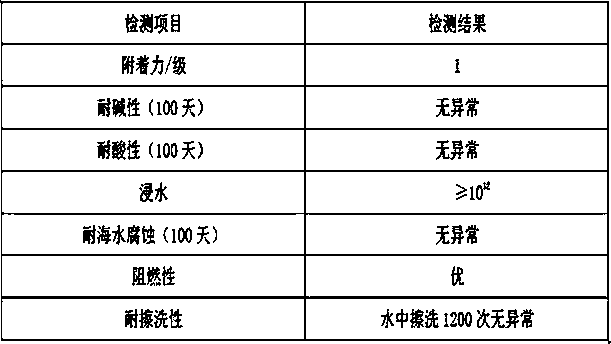

Image

Examples

Embodiment 1

[0050] A marine paint, comprising the following raw materials in parts by weight: 80 parts of epoxy resin; 50 parts of acrylic resin; 20 parts of titanium dioxide; 15 parts of nano ferroferric oxide; 15 parts of nano titanium oxide; 18 parts of barite; 5 parts of hydrogenated castor oil; 3 parts of perlite; 2 parts of defoamer; 1 part of dispersant; 0.8 part of anti-settling agent; 0.5 part of thickener.

[0051] The nano ferroferric oxide has a particle size of 16 nm; the nano titanium oxide has a particle size of 16 nm; the barite has a whiteness of 88% and a mesh number of 1250 mesh.

[0052] A ship paint, the steps are as follows:

[0053] (1) Heat the epoxy resin and acrylic resin in a water bath at 45°C and stir for 20 minutes to obtain a mixture A for use;

[0054] (2) The ferroferric oxide and titanium oxide are spheroidized in the particle compounding system, the condition is controlled at a speed of 11000 rpm, the treatment time is 5 minutes, and the temperature is controlle...

Embodiment 2

[0057] A marine paint, comprising the following raw materials in parts by weight: 90 parts of epoxy resin; 60 parts of acrylic resin; 25 parts of titanium dioxide; 17 parts of nanometer ferroferric oxide; 17 parts of nanometer titanium oxide; 19 parts of barite; 8 parts of hydrogenated castor oil; 4 parts of perlite; 2 parts of defoamer; 1 part of dispersant; 0.8 part of anti-settling agent; 0.7 part of thickener.

[0058] The nano ferroferric oxide has a particle size of 18 nm; the nano titanium oxide has a particle size of 18 nm; the barite has a whiteness of 90% and a mesh number of 2000 meshes;

[0059] A ship paint, the steps are as follows:

[0060] (1) Heat the epoxy resin and acrylic resin in a 60°C water bath and stir for 20 minutes to obtain a mixture A, which is ready for use;

[0061] (2) The ferroferric oxide and titanium oxide are spheroidized in a particle compounding system, the condition is controlled at a speed of 11000 rpm, a treatment time of 15 minutes, and a temp...

Embodiment 3

[0064] A marine paint, comprising the following raw materials in parts by weight: 100 parts of epoxy resin; 65 parts of acrylic resin; 28 parts of titanium dioxide; 18 parts of nano ferroferric oxide; 18 parts of nano titanium oxide; 20 parts of barite; 8 parts of hydrogenated castor oil; 4 parts of perlite; 3 parts of defoamer; 1.5 parts of dispersant; 1 part of anti-settling agent; 1 part of thickener.

[0065] The nano ferroferric oxide has a particle size of 20 nm; the nano titanium oxide has a particle size of 20 nm; the barite has a whiteness of 95% and a mesh number of 2000 mesh;

[0066] A ship paint, the steps are as follows:

[0067] (1) Heat the epoxy resin and acrylic resin in a water bath at 55°C and stir for 35 minutes to obtain a mixture A, which is ready for use;

[0068] (2) The ferroferric oxide and titanium oxide are spheroidized in a particle compounding system, the conditions are controlled at a speed of 15000 rpm, a processing time of 15 minutes, and a temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com