Chemical adsorbent, application of chemical adsorbent in purification of tert-butanol co-produced through co-oxidation method and method

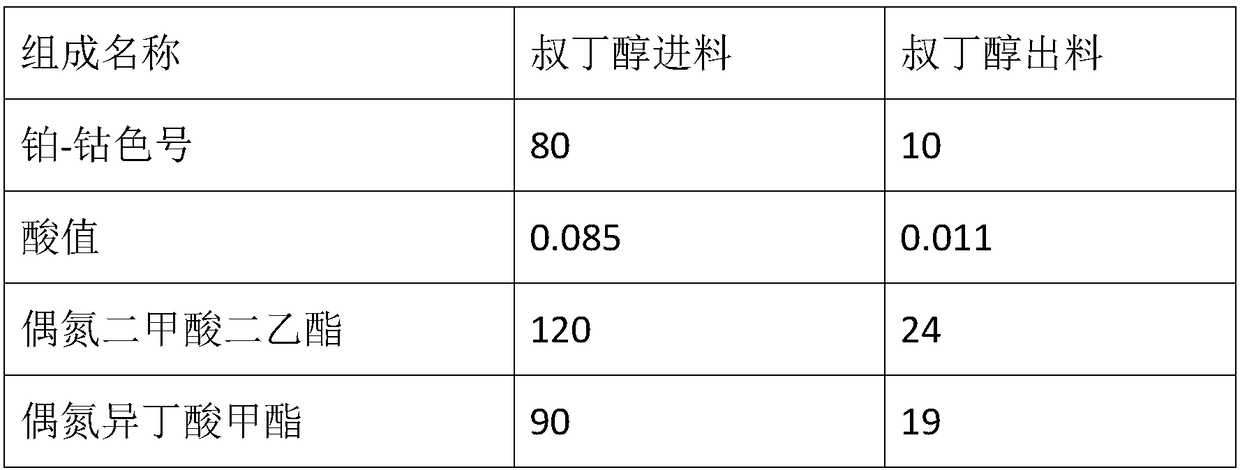

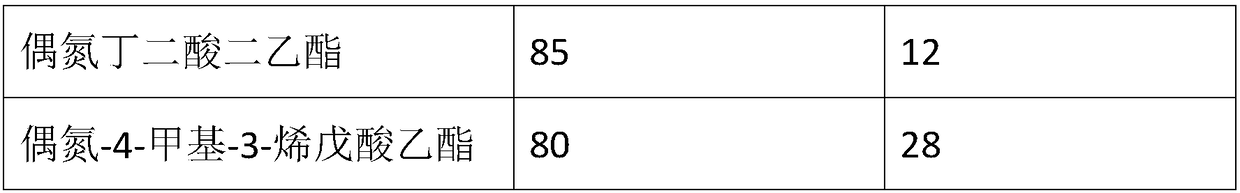

A technology of chemical adsorption and co-oxidation, applied in chemical instruments and methods, separation/purification of hydroxyl compounds, inorganic chemistry, etc., can solve problems affecting the use of downstream customers, yellowing of tert-butanol products, growth of platinum and cobalt color numbers, etc. problem, achieve optimal adsorption effect, long operation cycle, and solve the effect of acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] The coal slag of the gasification unit (its main component is SiO 2 48%, Al 2 o 3 36%, 8% iron oxide, 1.5% calcium oxide, 0.5% titanium oxide and 5.6% residual carbon. ), activated carbon powder, graphene, and NaOH powder are uniformly mixed in a mass ratio of 2.5:1:0.5:0.2, roasted at 800°C for 110min in a nitrogen atmosphere in a tube furnace, cleaned and soaked with 3% hydrochloric acid solution for 2h, and rinsed with water until Neutral, dry at 105°C for 3 hours to obtain the treated cinder-based activated carbon carrier.

[0041] The 2wt% ethanol solution of manganese acetate, palladium acetate, and citric acid is mixed according to the mass ratio of 2:0.4:2, and then add 60% of the activated carrier based on the total mass of the obtained mixture and the cinder-based active carrier, and soak at 60°C. Prepared for 72 hours, then dried at 85°C for 12 hours, and baked in a muffle furnace at 350°C for 2 hours. Obtain the manganese oxide chemical adsorbent 1 of ...

preparation example 2

[0043] The coal slag of the gasification unit (its main component is SiO 2 48%, Al 2 o 3 36%, 8% iron oxide, 1.5% calcium oxide, 0.5% titanium oxide and 5.6% residual carbon. ), activated carbon powder, graphene, and NaOH powder are uniformly mixed in a mass ratio of 2:0.5:0.4:0.1, roasted at 800°C for 90min in a nitrogen atmosphere in a tubular furnace, cleaned and soaked with 3% hydrochloric acid solution for 2h, and rinsed with water until Neutral, dry at 105°C for 3 hours to obtain the treated cinder-based activated carbon carrier.

[0044] The 2wt% ethanol solution of manganese acetate, palladium acetate and citric acid is mixed according to the ratio of 2:0.5:3, and then 60% of the activated carrier based on the total mass of the obtained mixture and the cinder-based active carrier is added, and soaked at 60°C 48h, then dried at 85°C for 12h, and baked in a muffle furnace at 350°C for 2h. Obtain the manganese oxide adsorbent 2 of described coal slag-based activated...

preparation example 3

[0046] The coal slag of the gasification unit (its main component is SiO 2 48%, Al 2 o 3 36%, 8% iron oxide, 1.5% calcium oxide, 0.5% titanium oxide and 5.6% residual carbon. ), activated carbon powder, graphene, and NaOH powder are uniformly mixed in a mass ratio of 2:1:0.5:0.2, roasted at 800°C for 90min in a nitrogen environment in a tube furnace, cleaned and soaked with 3% hydrochloric acid solution for 2h, and rinsed with water until Neutral, dry at 105°C for 3 hours to obtain the treated cinder-based activated carbon carrier.

[0047] The 2wt% ethanol solution of titanium acetate, platinum acetate, and citric acid is mixed according to the ratio of 1.8:0.5:3, and then 60% of the activated carrier based on the total mass of the obtained mixture and the cinder-based active carrier is added, and soaked at 60°C 48h, then dried at 85°C for 12h, and baked in a muffle furnace at 350°C for 2h. The cinder-based activated carbon-loaded nano-Pt modified titanium oxide adsorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com