Ordered mesoporous gamma-MnO2 catalyst and preparation method and application thereof

A catalyst and mesoporous technology, applied in the field of ordered mesoporous γ-MnO2 catalyst and its preparation, can solve the problems that the preparation method has not been reported yet, and achieve the effect of simple and controllable preparation method, low energy consumption and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

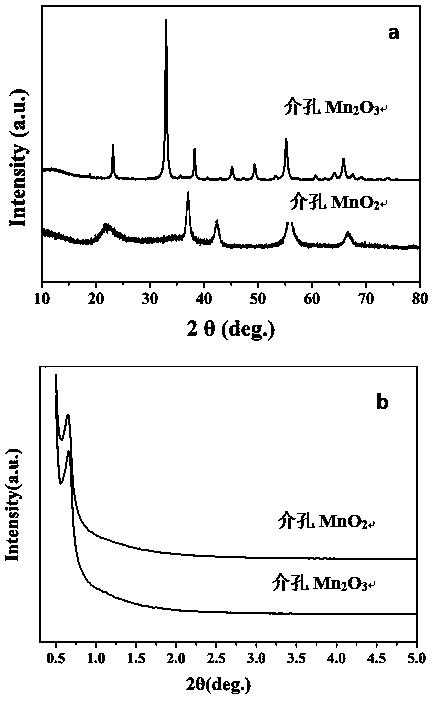

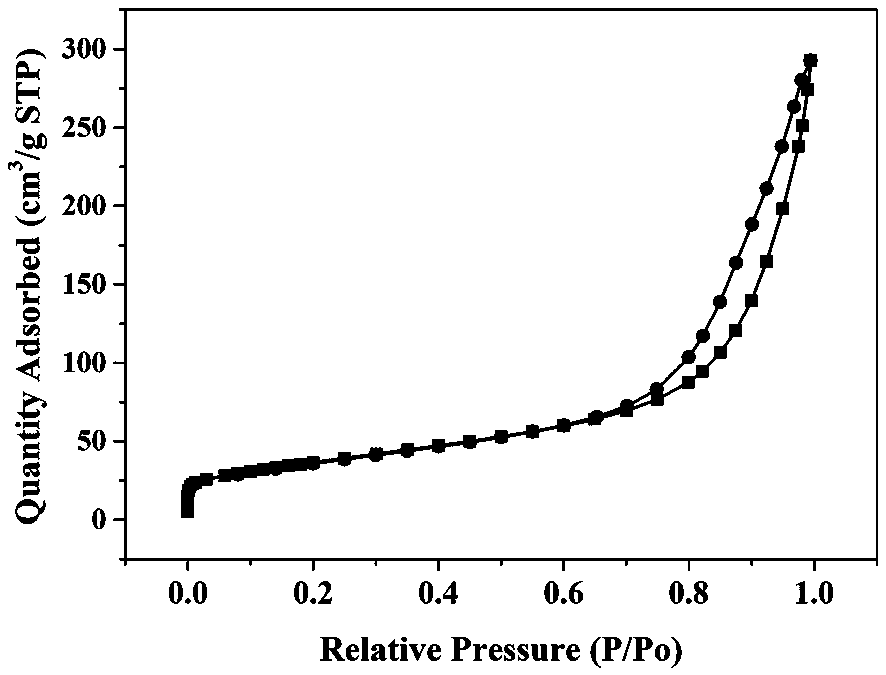

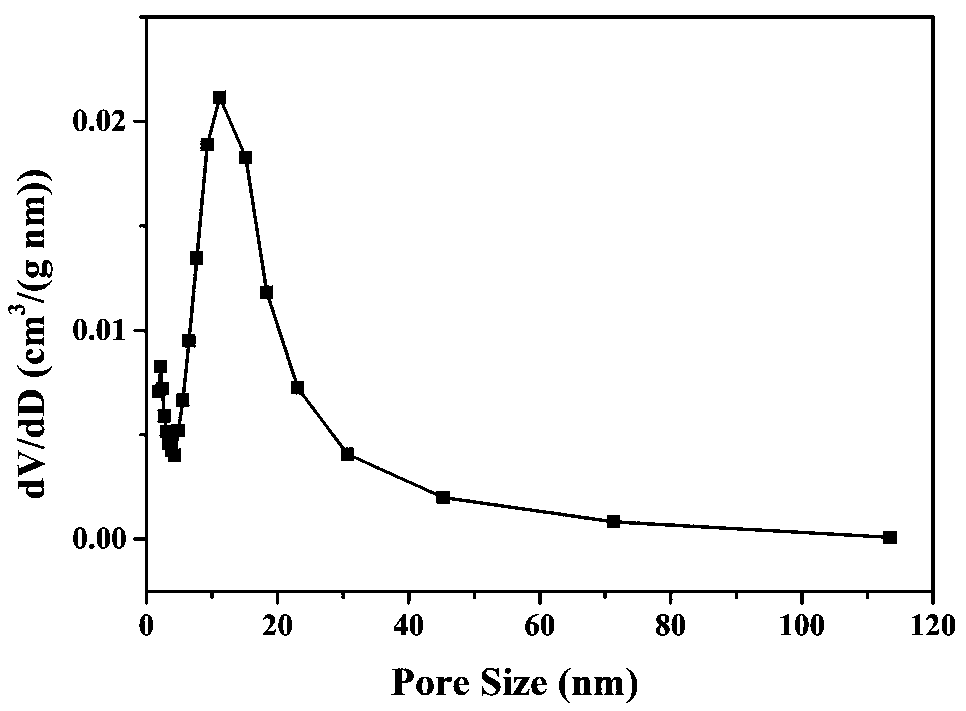

[0055] Example 1 An ordered mesoporous γ-MnO 2 catalyst

[0056] 1. Preparation method

[0057] This example provides an ordered mesoporous γ-MnO 2 Catalyst, its preparation method comprises the following steps:

[0058] (1) Add 1.0 g of KIT-6 mesoporous silica to 10 mL, 0.3 mol / L manganese nitrate ethanol solution, stir and impregnate at room temperature for 2 h, evaporate excess ethanol at 80 °C and dry it at 60 °C, and Preliminary calcination at 350°C for 3 hours in the atmosphere, with a heating rate of 1°C / min; repeat the impregnation and drying step 1 to 2 times, and finally calcine at a constant temperature of 650°C for 5 hours in the air atmosphere, with a heating rate of 1°C / min, to obtain high-filling Mn 2 o 3 precursor; then, the mesoporous Mn 2 o 3 The precursor was soaked and stirred in 2mol / L sodium hydroxide solution for 24h, centrifuged, washed, and dried to obtain the mesoporous Mn 2 o 3 Precursor;

[0059] (2) 1g of the above-mentioned mesoporous Mn ...

Embodiment 2

[0066] The preparation method of the catalyst of the present embodiment is substantially the same as that of Example 1, except that:

[0067] (1) In step (1), the final calcination temperature of the precursor is 600°C;

[0068] (2) In step (2), the obtained 1g mesoporous Mn 2 o 3 The precursor powder was added to 100mL, 3mol / L nitric acid solution, stirred at 80°C for 2h, and then centrifuged, washed and dried several times to obtain ordered mesoporous γ-MnO 2 catalyst.

[0069] Gained catalyst is analyzed by X-ray diffraction and electron microscope, and its result is identical with embodiment 1, and this catalyst is ordered mesoporous γ-MnO 2 catalyst.

Embodiment 3

[0071] The preparation method of the catalyst of the present embodiment is substantially the same as that of Example 1, except that:

[0072] (1) In step (1), the concentration of manganese nitrate ethanol solution is 0.9mol / L;

[0073] (2) In step (2), the obtained 1g mesoporous Mn 2 o 3 The precursor powder was added to 50mL, 5mol / L nitric acid solution, stirred at 120°C for 0.5h, and then centrifuged, washed and dried several times to obtain ordered mesoporous γ-MnO 2 catalyst.

[0074] Gained catalyst is analyzed by X-ray diffraction and electron microscope, and its result is identical with embodiment 1, and this catalyst is ordered mesoporous γ-MnO 2 catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com