A kind of preparation method and application of oxygen evolution catalyst

A catalyst and oxygen evolution technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve high cost, widespread application obstacles, affect energy conversion efficiency, etc. problem, to achieve the effect of improving the catalytic activity of oxygen evolution, low cost, and easy to realize industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 100 mg OMC was added 5 ml of 2m nitrate water bath 60 ° C for 30 min, and centrifugally washed once, and the mesoporous carbon was obtained.

[0043] (2) Nickel nickel nitrate and hexahydrate of hexahydrate is weighed in a molar ratio of 1: 2, dissolved in 5 ml absolute ethanol.

[0044] (3) The OMC of step (1) was transferred to a solution of step (2) with 5 ml of ethanol, stirred for 10 min, then supera for 2 h, then stirred to dryness, resulting in powder. (Stir until the end, the sample will be a little tide, and can be dried after the step is completed).

[0045] (4) Place the powder of step (3) is placed in a tube furnace, and the argon atmosphere is 350 ° C. Calcination for 6 h.

[0046] Property characterization:

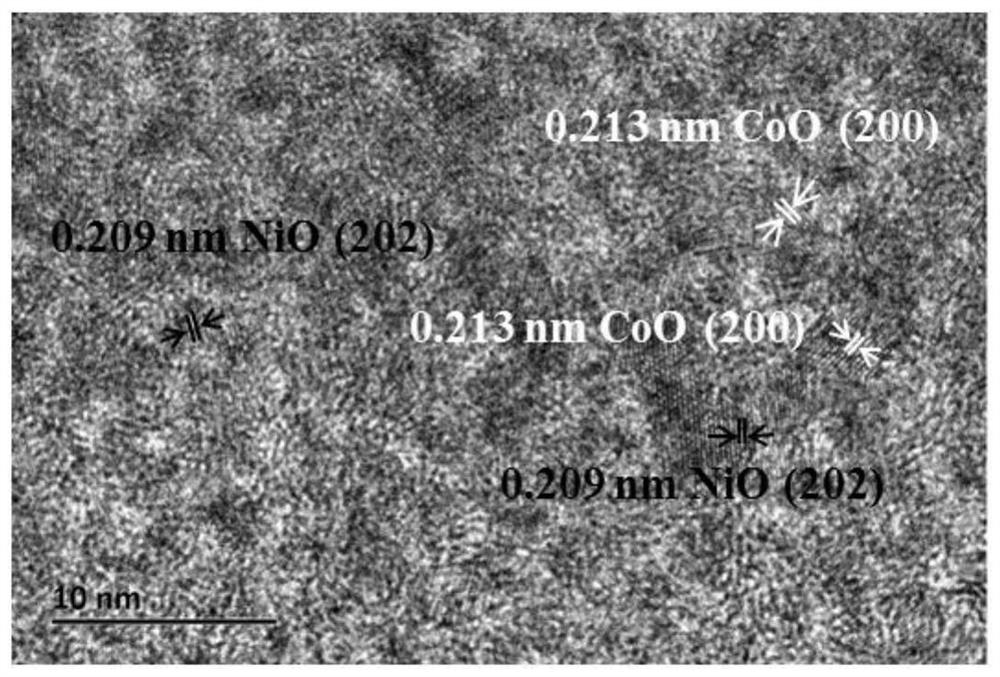

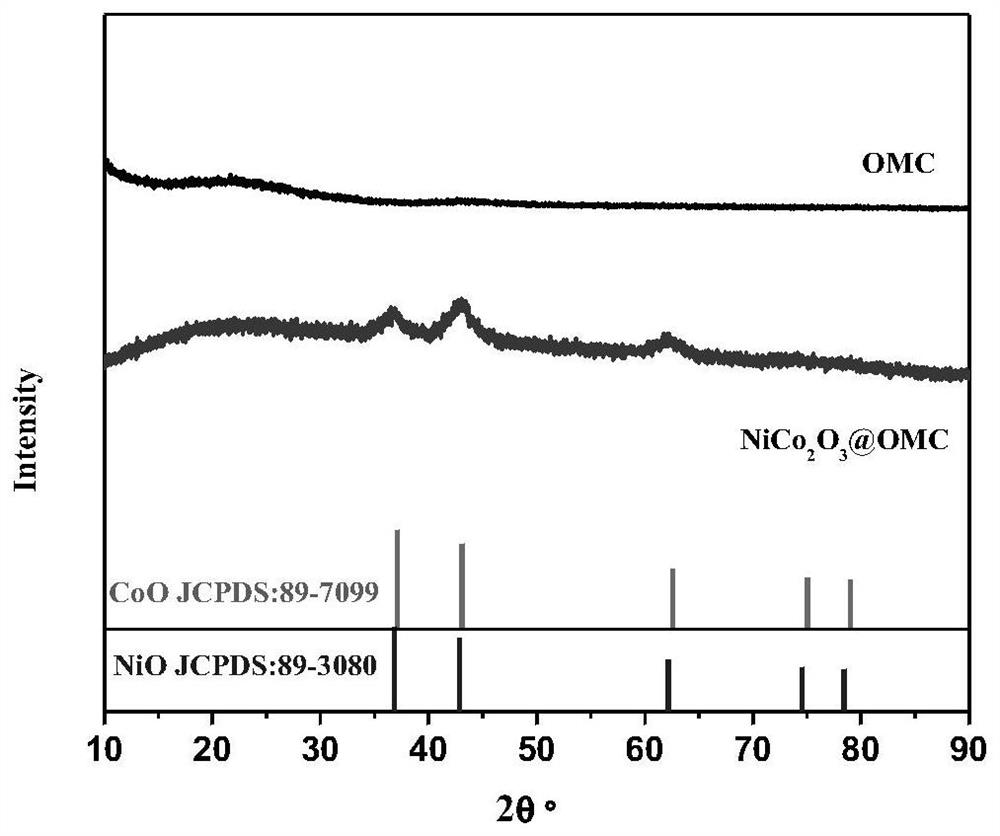

[0047] figure 1 The Nico obtained by Example 1 was shown 2 O 3 High resolution TEM image of @omc.

[0048] like figure 1 As shown, a nickel cobalt oxide is formed on the OMC, and the average particle diameter of the nickel cobalt oxide particles is 3-8...

Embodiment 2

[0051] Example 2 Nico 2 O 3 @OMC catalyst catalytic activity evaluation

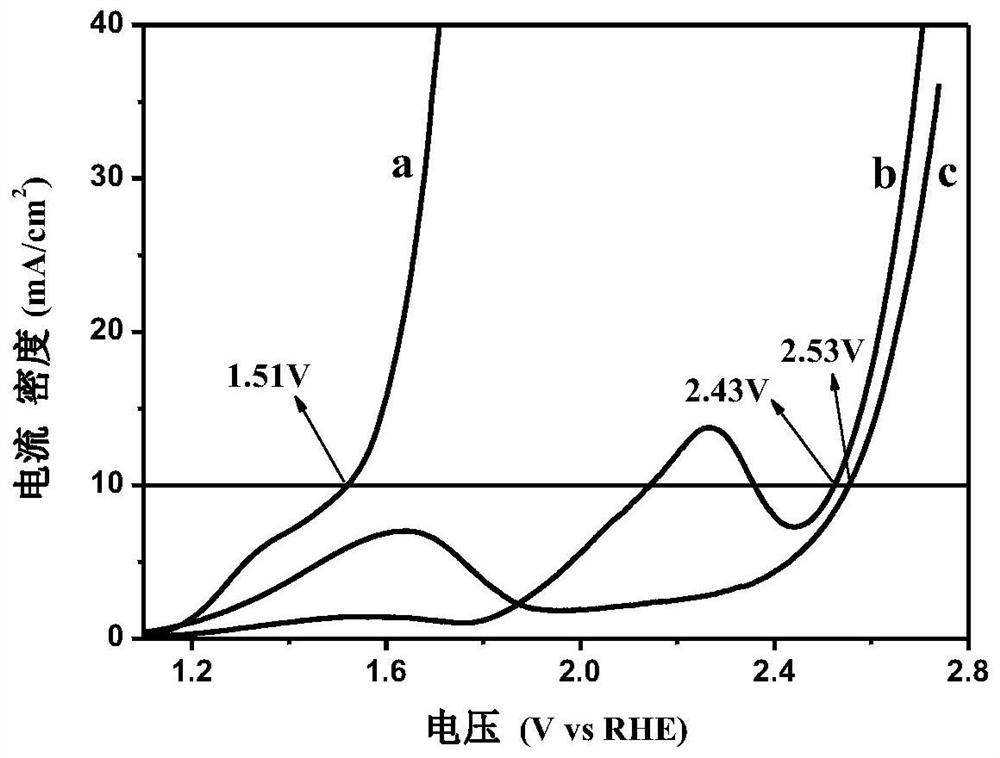

[0052] With 1 M NaOH as the electrolyte solution, Ag / AgCl is the reference electrode, the platinum network is the counter electrode, the glass-carbon electrode is the working electrode, the sweep is 5mV / s, and linearly scanned volts (LSV) on the Autolab PGSTAT 302N electrochemical workstation. Test, such as image 3 Indicated. Nico prepared by Example 1 2 O 3 @Omc catalyst (0.567mg / cm 2 ) 10 mA / cm in alkaline electrolyte solution 2 The potential at the current density is 1.51V, and the corresponding over-potential is 280mV, which is superior to Nico. 2 O 3 + OMC (1200mV) and OMC (1300mV)

Embodiment 3

[0053] Example 3 Nico 2 O 3 @OMC catalyst in electrocatalytic stability appraisal under constant potential

[0054] like Figure 4 As shown in 1 M NaOH as the electrolyte solution, Ag / AgCl is the reference electrode, the platinum network is a counter electrode, and the glass-carbon electrode is a working electrode, and the electrochemical stability is measured at a constant potential. After 20000s, the current drops. 25.7%, indicating Nico prepared in Example 1 2 O 3 The @omc catalyst has good stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com