Formula, preparation method and application of LAS-series glass ceramic abrasive binding agent

A glass-ceramic and bonding agent technology, applied in abrasives, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient content of microcrystalline phase, polluted macrofluoride, low microcrystallization temperature, etc. The effect of low crystallization heat treatment temperature, high apparent porosity and moderate density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Glass-ceramics were prepared by conventional methods, from Na 3 PO 4 and KNO 3 Introduce flux alkali metal oxide Na 2 O and K 2 O. By (wt%): SiO 2 48, Al 2 o 3 20, Li 2 O 8, B 2 o 3 15.5, Na 2 O 1,K 2 O 1, MgO 1, ZnO 1, BaO 0.5, TiO 2 4. Accurately weigh and mix evenly, first pre-fire at 900°C for 0.5h with a silicon carbide rod electric furnace, then raise to 1200-1300°C at a rate of 5°C / min, keep warm for 2-4h to obtain molten glass.

[0037] Part of the molten glass is poured into a preheated mold for molding, annealed in a muffle furnace to obtain a basic glass sample, which is used to observe the main crystal phase and morphology characteristics of the glass-ceramic, measure the thermal expansion coefficient, and conduct thermal analysis, etc. The nucleation temperature and crystallization temperature of the crystal glass, formulate the heat treatment temperature system; the remaining glass liquid is water-quenched, dried, crushed and sieved to obta...

Embodiment 2

[0040] By (wt%): SiO 2 50, Al 2 o 3 18.Li 2 O 7, B 2 o 3 12, Na 2 O2,K 2 O1, MgO3, ZnO2, BaO1, TiO 2 4. Accurately weigh and mix evenly, first use a silicon carbide rod electric furnace to pre-fire at 900°C for 0.5h, then raise it to 1200-1300°C at a rate of 5°C / min, and keep it warm for 2-4h to obtain molten glass. After being released from the furnace, the samples used for performance testing are poured into preheated molds and placed in a muffle furnace for annealing; the rest of the molten glass is crushed, dried and ground for later use.

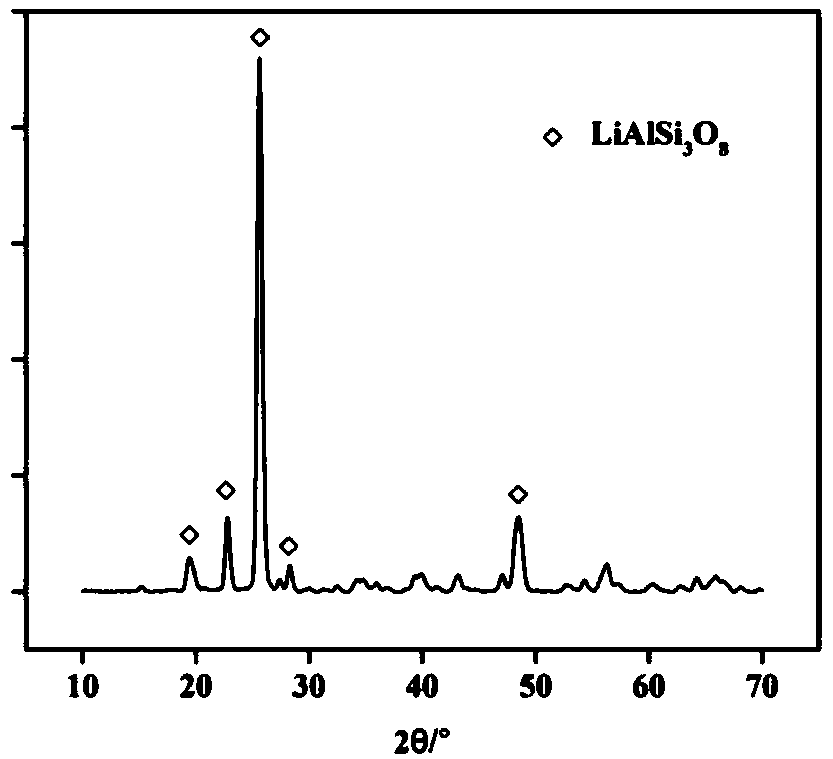

[0041] The formed basic glass was subjected to heat treatment, and the process conditions were: nucleation temperature 480°C, crystallization temperature 670°C, heat preservation for 2 hours, and a glass-ceramic sample was obtained. see image 3 , the XRD diffraction peaks of the glass-ceramic sample are consistent with the data of the JCPDF#35-0706 card, indicating that the main crystal phase of the glass-ceramics after he...

Embodiment 3

[0043] By (wt%): SiO 2 56.07, Al 2 o 3 16.16, Li 2 O 6.23, B 2 o 3 8.31, Na 2 O 0.9,K 2 O 0.97, MgO 4.15, ZnO 2.08, BaO 0.52, TiO 2 4.15; Accurately weigh and mix evenly, pre-fire in a silicon carbide rod electric furnace at 900°C for 0.5h, then raise to 1200-1300°C at a rate of 5°C / min, keep warm for 2-4h, obtain molten glass, and take it out of the furnace , the samples used for performance testing are poured into the preheated mold and annealed; the remaining glass liquid is crushed, dried and ground for later use.

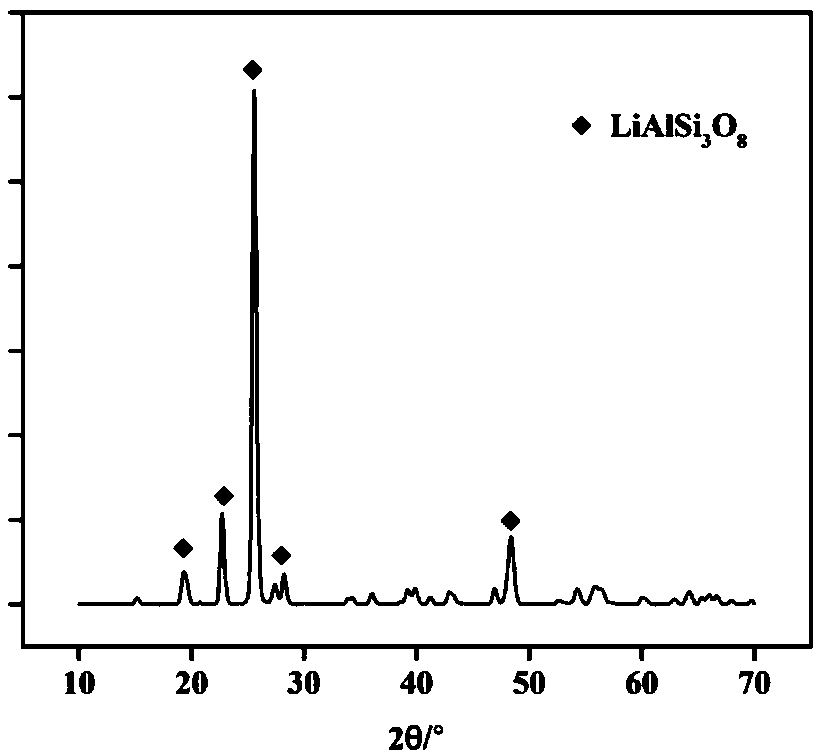

[0044] The formed basic glass was subjected to heat treatment, and the technological conditions were: nucleation temperature 490°C, crystallization temperature 680°C, heat preservation for 2 hours, and a glass-ceramic sample was obtained. see Figure 5 , the XRD diffraction peaks of the glass-ceramic sample are consistent with the J JCPDF#35-0794 card data, indicating that the main crystal phase of the glass-ceramics after heat treatment is β-spodu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com