Titanium dioxide/carbon nitride/Cu-ZSM-5 photocatalyst and preparation method of titanium dioxide/carbon nitride/Cu-ZSM-5 photocatalyst

A photocatalyst, titanium dioxide technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high electron-hole recombination rate, complex preparation conditions, easy wear and tear of catalysts, etc. The effect of strength, simplifying the operation process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

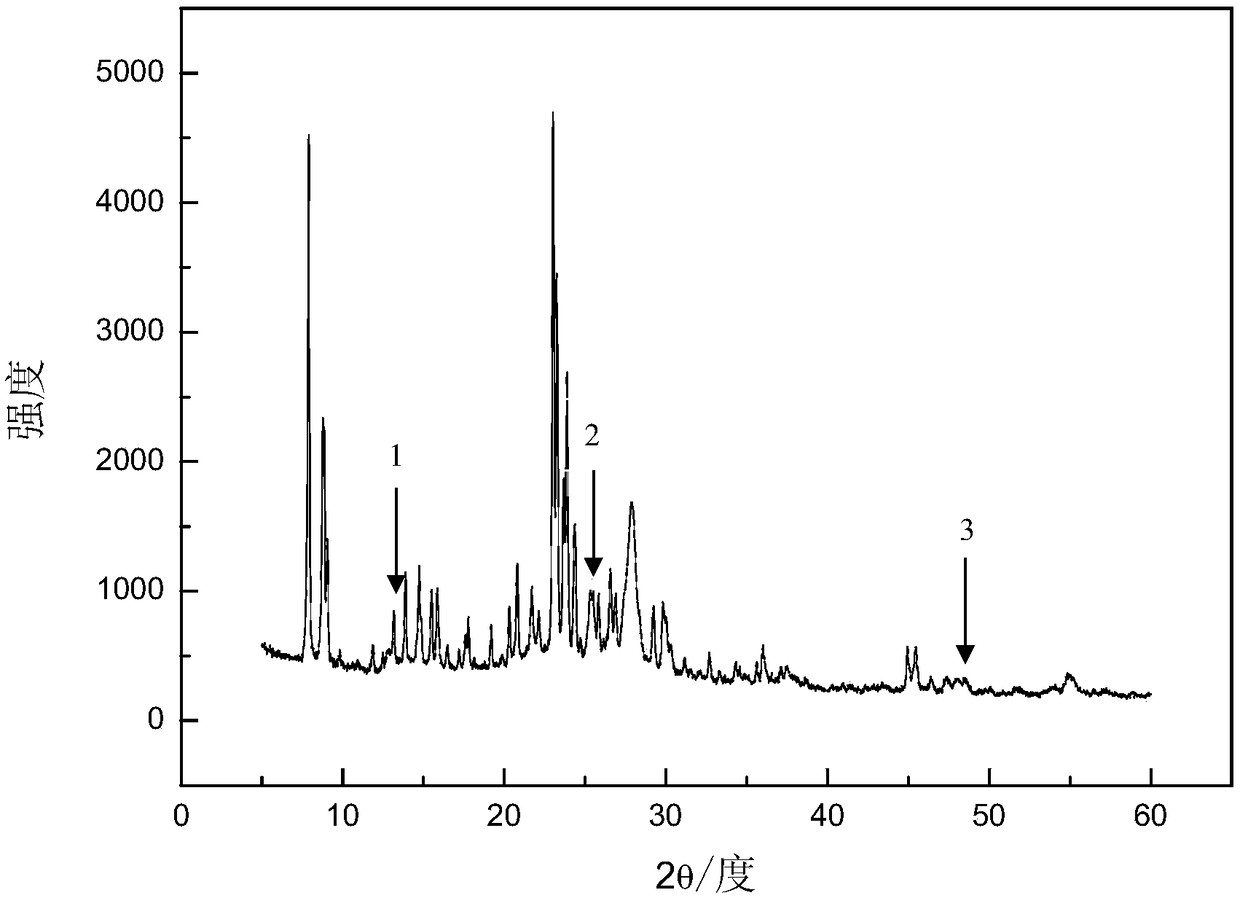

Image

Examples

Embodiment 1

[0044] (1) Wash 100 g of Cu-ZSM-5 with 0.01 mol / L sodium nitrate solution, deionized water, suction filtration, and dry at 105° C. for later use.

[0045] (2) Take 25mL of ethanol, add 7mL of tetrabutyl titanate dropwise to absolute ethanol and stir for 30min, denoted as A solution, take 15ml of absolute ethanol, add 3mL of acetic acid and 1mL of deionized water to it and stir, A solution is slowly added to the above solution, and TiO is obtained after standing and aging 2 Precursor.

[0046] (3) TiO to be prepared 2 The precursor and Cu-ZSM-5 were uniformly mixed and sonicated for 30 min, and then dried at 105-130 °C.

[0047] (4) The obtained Cu-ZSM-5 after drying was evenly mixed with 20 g of melamine.

[0048] (5) The mixed catalyst was placed in a tube furnace, and the temperature was controlled by a program to increase the temperature at a rate of 3°C / min. The temperature was raised from room temperature to 250°C. After 1 hour of constant temperature, the temperature ...

Embodiment 2

[0064] (1) Wash 100 g of Cu-ZSM-5 with 0.01 mol / L sodium nitrate solution, deionized water, suction filtration, and dry at 105° C. for later use.

[0065] (2) Take 25mL of ethanol, add 7mL of tetrabutyl titanate dropwise to absolute ethanol and stir for 30min, denoted as A solution, take 15ml of absolute ethanol, add 3mL of acetic acid and 1mL of deionized water to it and stir, A solution is slowly added to the above solution, and TiO is obtained after standing and aging 2 Precursor.

[0066] (3) TiO to be prepared 2 The precursor was uniformly mixed with Cu-ZSM-5 and 20 g of urea and sonicated for 30 min.

[0067] (4) drying the sonicated catalyst at 105-130°C.

[0068] (5) The catalyst is placed in a tube furnace, and the temperature is controlled by a program. The temperature rise rate is 3°C / min, and the temperature is raised from room temperature to 250°C. Constant temperature for 2h, slowly cooled to room temperature.

[0069] (6) Wet with 0.73 mol / L sodium silicate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com