An aqueous mineral binder for a silicon negative electrode of a lithium ion battery and a preparation method and application thereof

A technology of lithium-ion batteries and water-based minerals, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as high cost and complicated preparation process, and achieve low production cost and simple operation , Improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

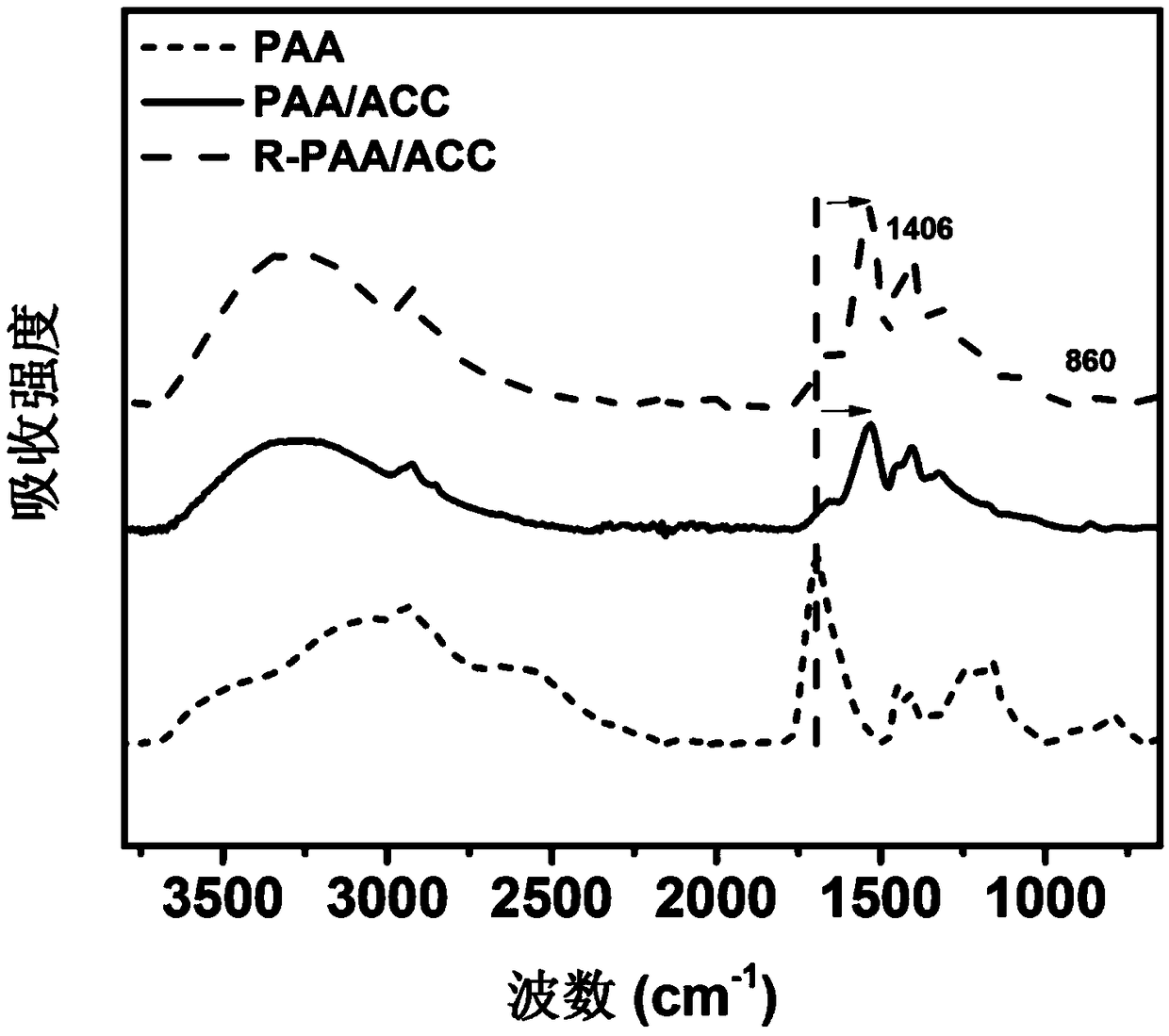

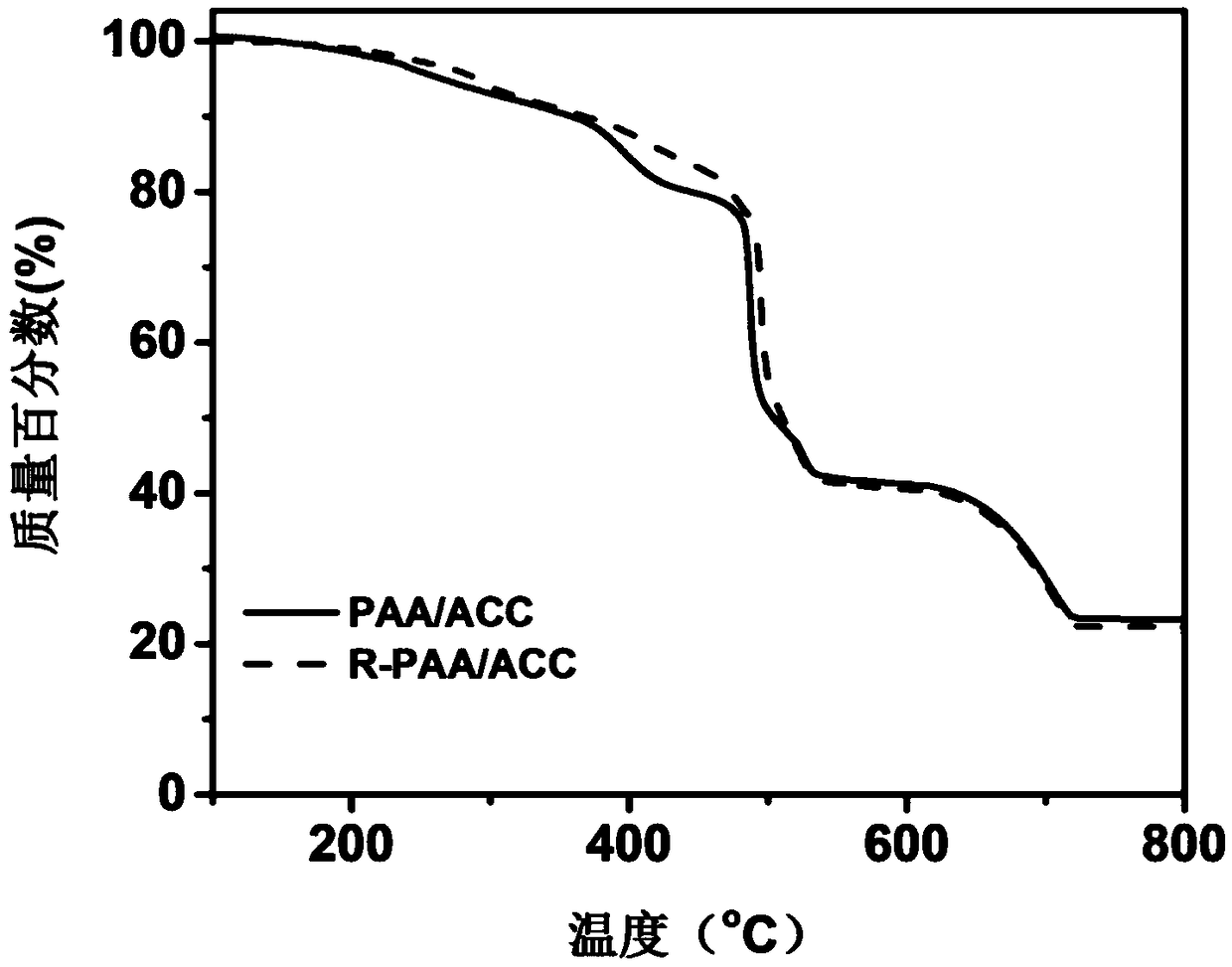

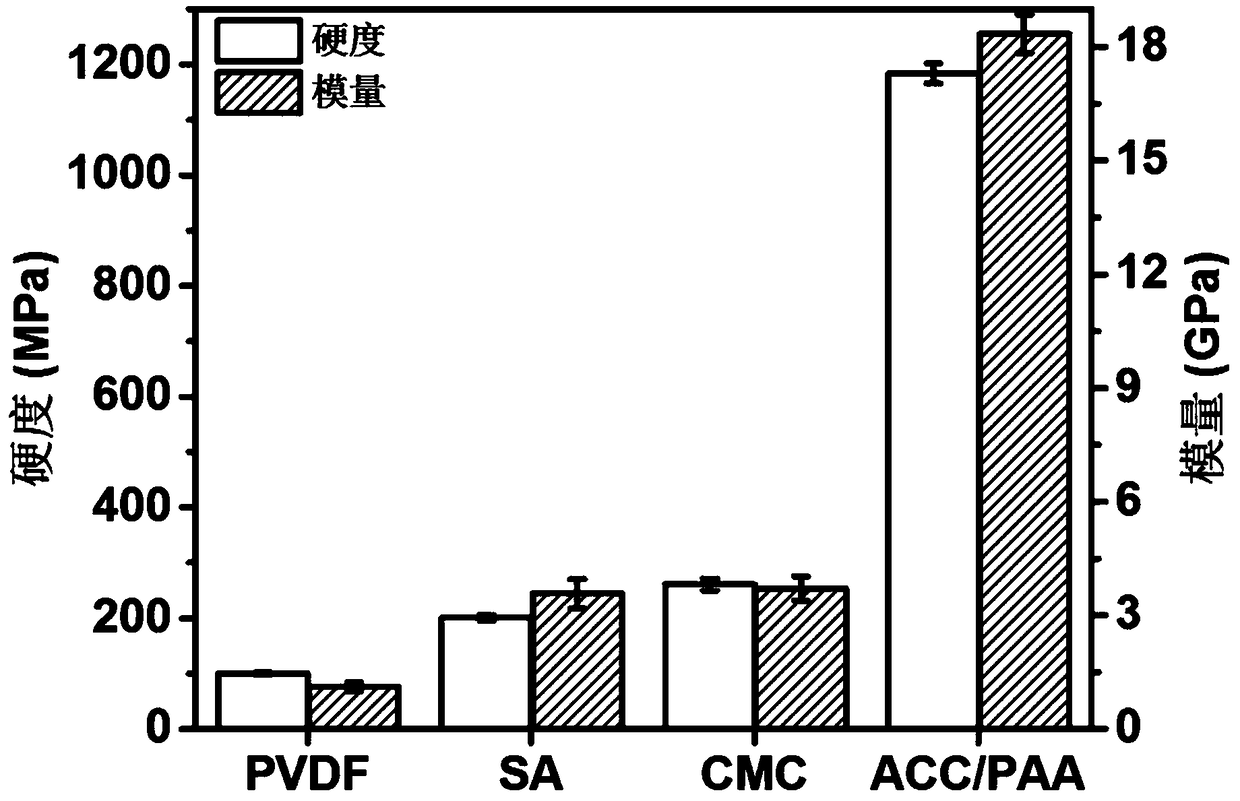

[0029] (1) Dissolve 1g of polyacrylic acid (PAA) with a molecular weight of one hundred thousand and 1.5g of calcium chloride in 100ml of deionized water and stir for 10min, then dissolve 1.5g of sodium carbonate in 100ml of deionized water, and stir for 10min; then add sodium carbonate The solution was added to the PAA and calcium ion mixed solution and stirred for 1 hour to obtain a lumpy precipitate, which was washed with deionized water. The white lumps were the PAA / ACC hydrogel;

[0030] (2) Take 0.1g of PAA / ACC hydrogel, dissolve it in 0.1M hydrochloric acid solution, and stir for 2h to obtain a PAA / ACC solution;

[0031] (3) Weigh 40mg of silicon powder (particle size 100~700nm), 5mg of carbon black conductive agent, add them to a mortar, grind evenly, add 5mg of PAA / ACC solution; then stir for 12h to form a uniform slurry; Spread it on the copper foil of the current collector and place it in an ammonia atmosphere to react for 20 minutes; then place the pole piece in a vacuu...

Embodiment 2

[0038] (1) Dissolve 1g of 200,000 molecular weight polyacrylic acid (PAA) and 1.5g of calcium chloride in 100ml of deionized water, stir for 10min, then dissolve 1.5g of sodium carbonate in 100ml of deionized water, and stir for 10min; then add carbonic acid Add the sodium solution to the mixed solution of PAA and calcium ions, stir for 1 hour to obtain a lumpy precipitate, which is cleaned with deionized water. The white lumps are PAA / ACC hydrogel;

[0039] (2) Take 0.1g of PAA / ACC hydrogel, dissolve it in 0.1M hydrochloric acid solution, and stir for 2h to obtain a PAA / ACC solution;

[0040] (3) Weigh 40mg of silicon powder (particle size about 100-700nm) and 5mg of carbon black conductive agent, add them to a mortar, grind them evenly, add PAA / ACC solution (including PAA / ACC 5mg); then stir for 12h, A uniform slurry is formed; the slurry is spread on the copper foil of the current collector and placed in an ammonia atmosphere to react for 20 minutes; then the pole pieces are dri...

Embodiment 3

[0043] (1) Dissolve 2g of polyacrylic acid (PAA) with a molecular weight of 100,000 and 3g of calcium chloride in 100ml of deionized water and stir for 10min, then dissolve 3g of sodium carbonate in 100ml of deionized water, and stir for 10min; then add the sodium carbonate solution The mixed solution of PAA and calcium ions is stirred for 1 hour to obtain a lumpy precipitate, which is washed with deionized water. The white lumps are PAA / ACC hydrogel;

[0044] (2) Take 0.2g of PAA / ACC hydrogel, dissolve it in 0.1M sulfuric acid solution and stir for 2h to obtain a PAA / ACC solution;

[0045] (3) Weigh 40mg of silicon powder (particle size about 100-700nm) and 5mg of carbon black conductive agent, add them to a mortar, grind them evenly, add PAA / ACC solution (including PAA / ACC 5mg); then stir for 12h, A uniform slurry is formed; the slurry is spread on the current collector copper foil and placed under ammonium carbonate to react for 20 minutes; then the pole pieces are placed in a 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse capacity | aaaaa | aaaaa |

| Inverse capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com